Ladder for high-rise steel structure construction

A steel structure construction and high-rise technology, which is applied to the on-site preparation of building components, building construction, and construction, etc., can solve problems such as inability to meet demand, and achieve the effects of reducing occupied space, stabilizing fixed points, and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

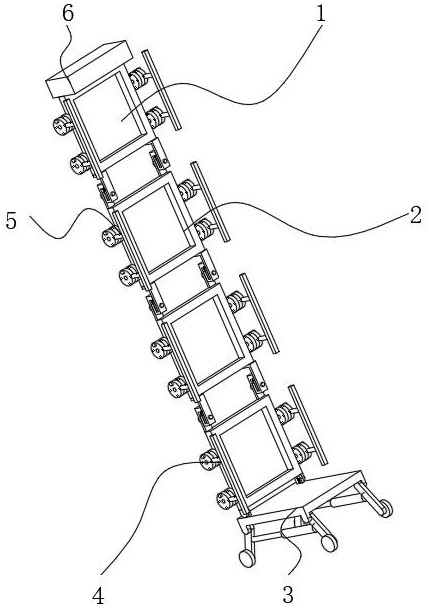

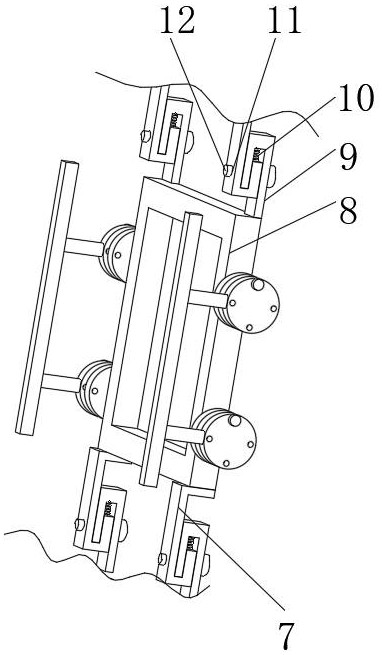

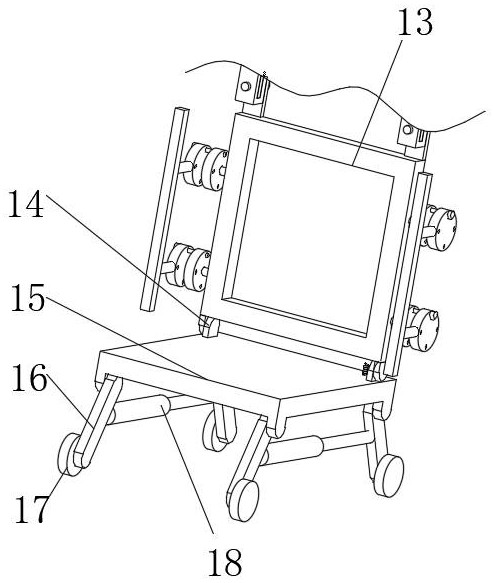

[0035] A ladder used for high-rise steel structure construction, such as figure 1 As shown, it includes top stair sections 1 interlocked with each other, at least one set of intermediate stair sections 2 and bottom stair sections 4, the top of the top stair sections 1 is provided with a top fixing assembly 6, and the bottom of the bottom stair sections 4 The bottom support assembly 3 is provided, and the outer walls of both sides of the top ladder section 1, the intermediate ladder section 2, and the bottom ladder section 4 are provided with guardrail assemblies 5, and the intermediate ladder section 2 includes two hooks-7, a frame One 8 and two hooks two 9, the two hooks one 7 are respectively welded to the outer walls on both sides of the bottom of the frame one 8, and the two hooks two 9 are respectively welded to the outer walls on both sides of the top of the frame one 8, and the Hook one 7 cooperates with hook two 9, and the inwalls of described hook one 7 and hook two 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com