Electromechanical telescopic control mechanism

A telescopic control and electromechanical technology, applied in the direction of electromechanical devices, electrical components, mechanical equipment, etc., can solve problems such as error-prone retraction, affecting the effect of telescopic lifting, rusting of internal parts, etc., to avoid falling and improve rotation efficiency , the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

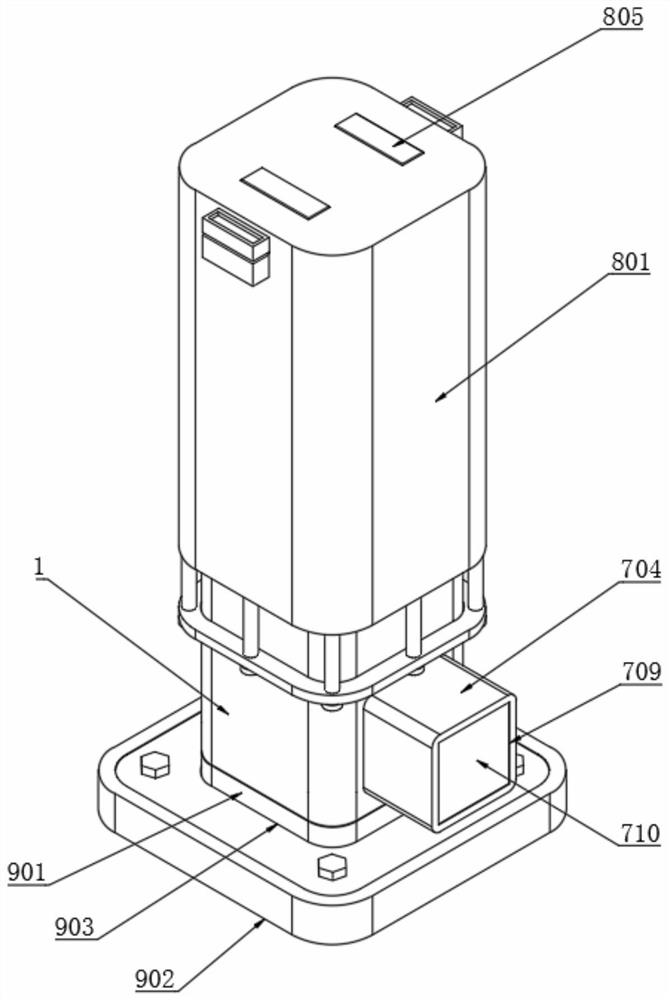

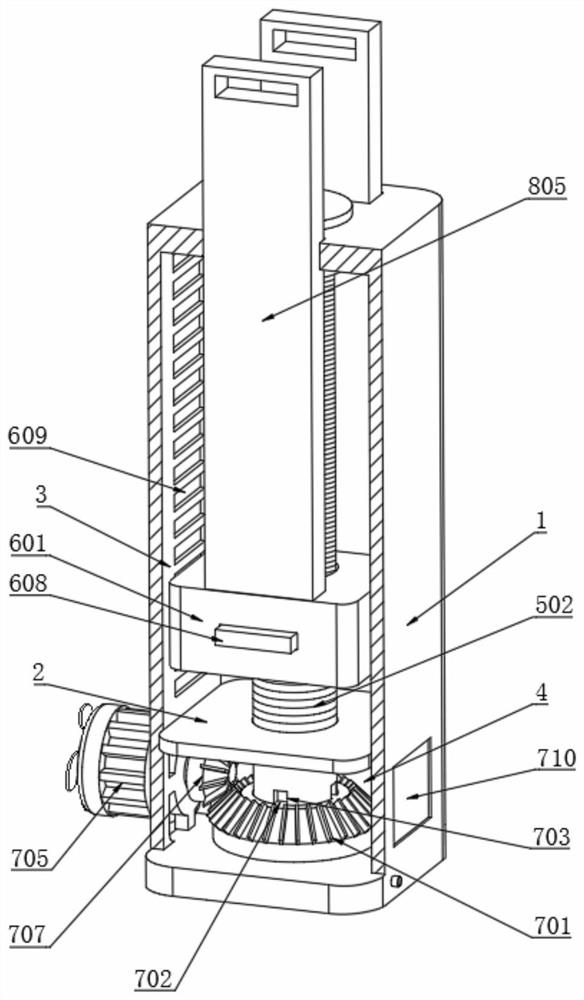

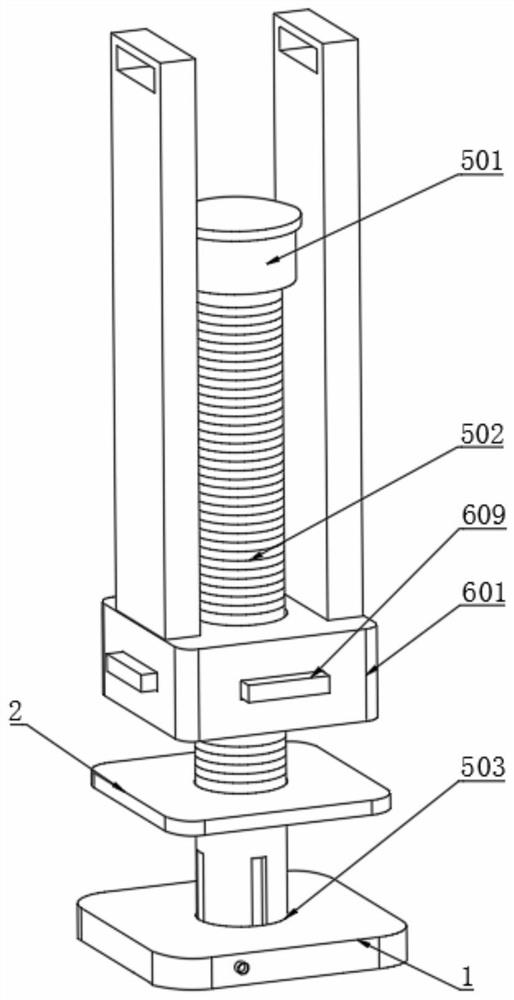

[0046] Example: such as Figure 1-10 As shown, the present invention provides a technical solution of a telescopic control mechanism for electromechanical use. A telescopic control mechanism for electromechanical use includes an inner shell 1, the inner wall of the inner shell 1 is fixedly connected with a partition plate 2, and the interior of the inner shell 1 corresponds to the partition plate 2. A lifting chamber 3 is provided at the top position, a transmission chamber 4 is provided at the bottom position corresponding to the partition plate 2 inside the inner shell 1, and a rotating lubrication mechanism 5 is provided at the bottom position corresponding to the transmission chamber 4 inside the inner shell 1, and the rotating lubrication mechanism 5 is provided at the bottom position corresponding to the transmission chamber 4. The mechanism 5 includes a shaft seat 501, a lifting rod 502, a rotating groove 503, a support spring 504, a support plate 505, an oil storage cha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap