Tire bursting test simulation device and simulation method thereof

A technology of blasting test and simulation device, applied in the direction of automobile tire testing, measuring device, vehicle testing, etc., can solve the problems of inability to apply a variety of tire and wheel models, poor operational flexibility, low test efficiency, etc., to improve diversification. , the effect of increasing range and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

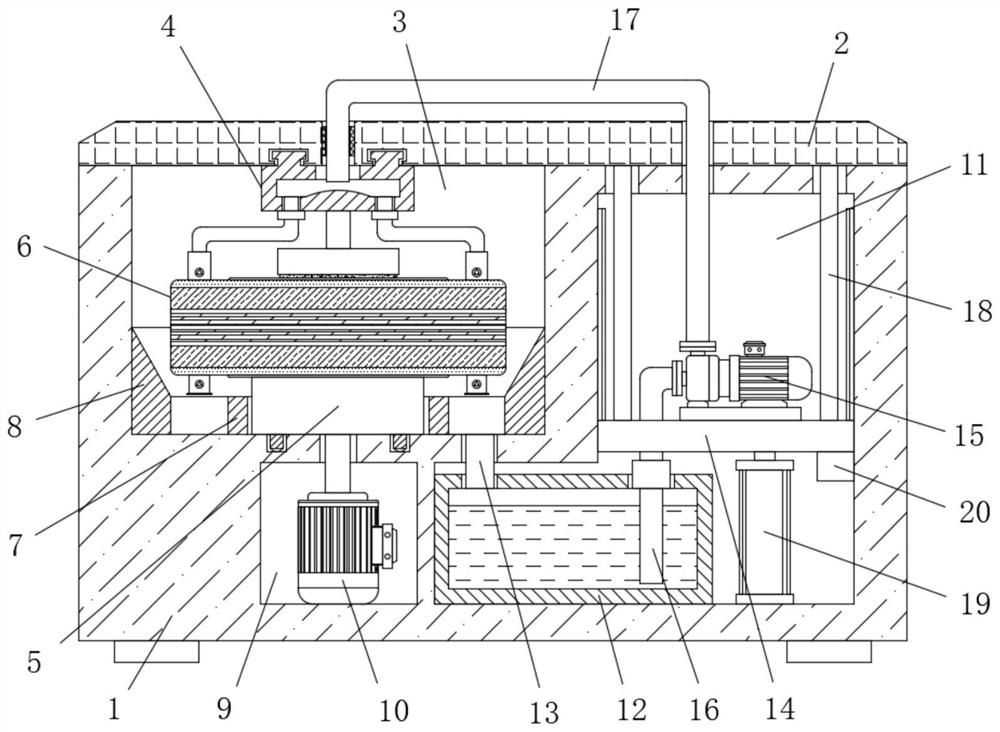

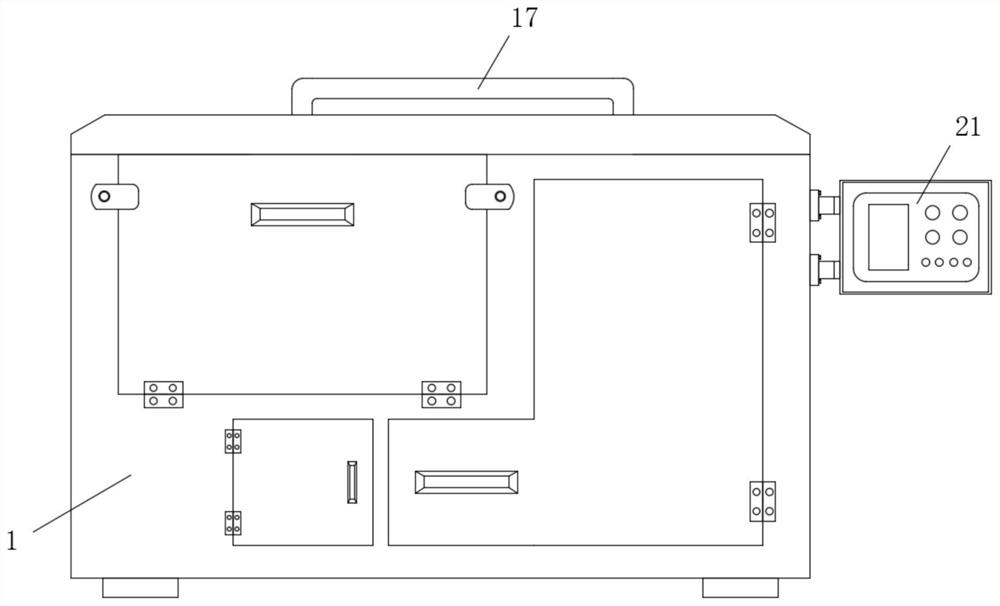

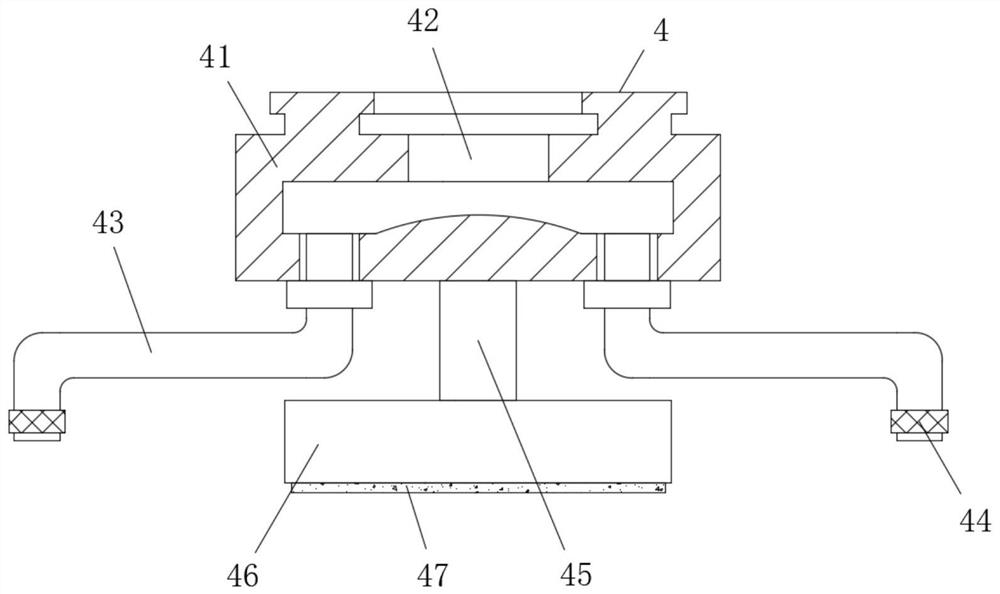

[0044] like Figure 1-10 As shown, a tire burst test simulation device includes a test box 1, the top of the test box 1 is in contact with a cover plate 2, a test chamber 3 is provided on the top side of the test box 1, and the bottom of the cover plate 2 is rotatably connected There is a water delivery mechanism 4 located in the test chamber 3. The bottom inner wall of the test chamber 3 is rotatably connected to a support mechanism 5. The top limit support of the support mechanism 5 is supported by a simulation mechanism 6, and the simulation mechanism 6 is connected to the support mechanism 5. The test chamber The inner wall of the bottom of 3 is provided with a drainage assembly, and the interior of the test box 1 is respectively provided with a drive chamber 9 and an L-shaped installation chamber 11. The cavity 3 is adjacent to one side of the drive cavity 9, the bottom inner wall of the drive cavity 9 is fixedly connected with the drive motor 10 that drives the support m...

Embodiment 2

[0052] This embodiment is as a further improvement of the previous embodiment: as Figure 1-10As shown, a tire burst test simulation device includes a test box 1, the top of the test box 1 is in contact with a cover plate 2, a test chamber 3 is provided on the top side of the test box 1, and the bottom of the cover plate 2 is rotatably connected There is a water delivery mechanism 4 located in the test chamber 3. The bottom inner wall of the test chamber 3 is rotatably connected to a support mechanism 5. The top limit support of the support mechanism 5 is supported by a simulation mechanism 6, and the simulation mechanism 6 is connected to the support mechanism 5. The test chamber The inner wall of the bottom of 3 is provided with a drainage assembly, and the interior of the test box 1 is respectively provided with a drive chamber 9 and an L-shaped installation chamber 11. The cavity 3 is adjacent to one side of the drive cavity 9, the bottom inner wall of the drive cavity 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com