Electrostatic chuck with charge dissipation coating

An electrostatic chuck and coating technology, applied in the direction of holding devices, circuits, and manufacturing tools that apply electrostatic attraction, can solve problems such as damage to sharp edges and limited utility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

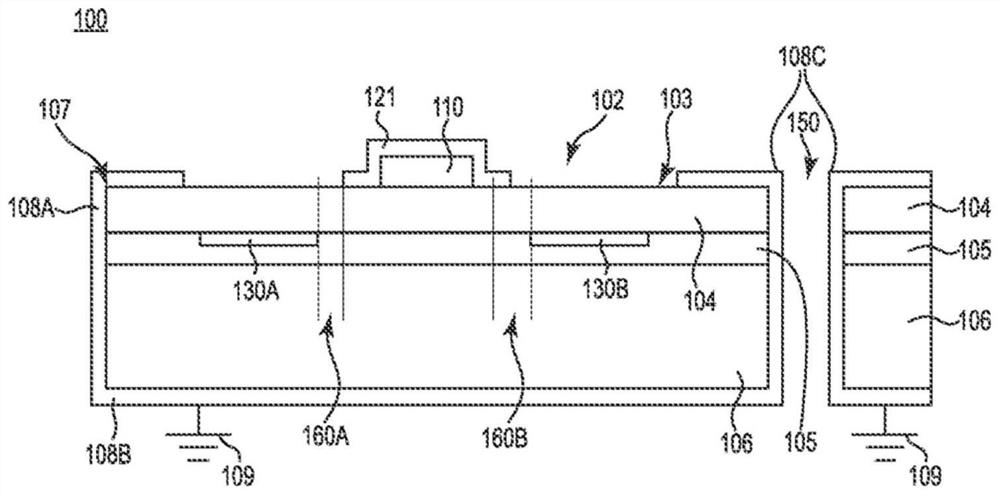

[0016] Various example implementations of novel wafer substrate unchucking structures that provide electrostatic chucks and methods for using this configuration to reduce charge buildup that cause wafer substrates to "stick" after the electrostatic chuck has been powered down are described below. example. Localized surface charges can lead to unintended wafer clamping even in the absence of an external voltage. Therefore, there is also a need for improved platen or chuck configurations that control charge buildup in electrostatic chucks.

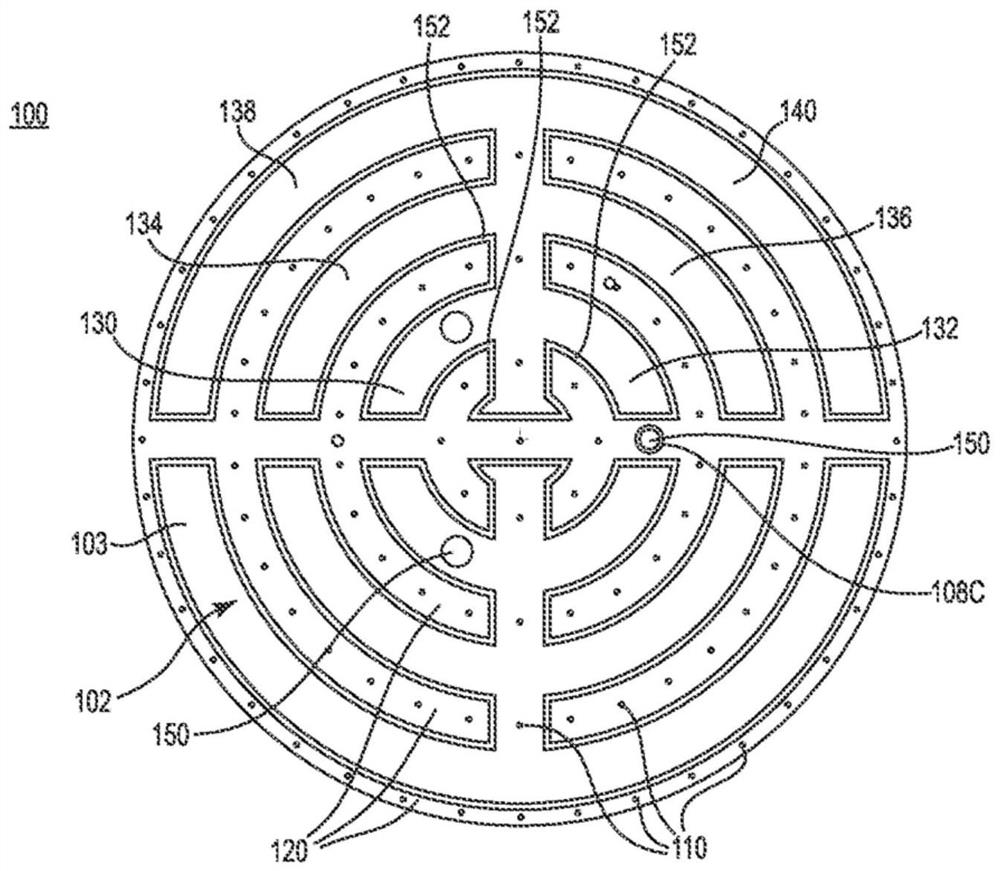

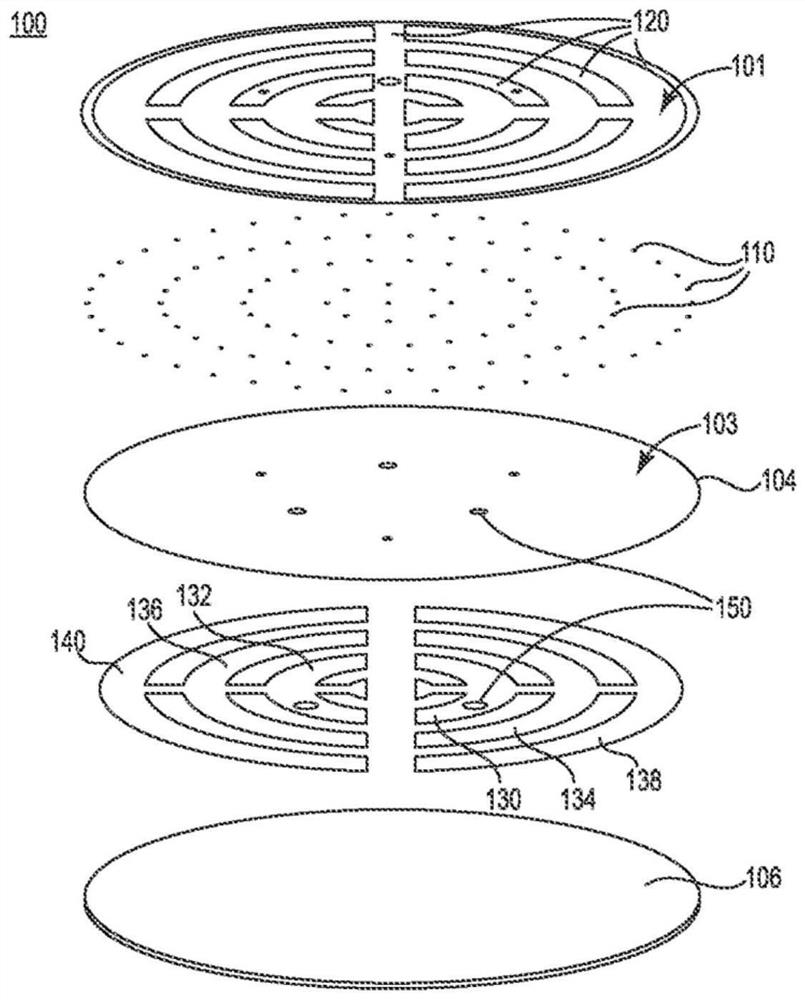

[0017] Referring now to the figures, figure 1 and 2 are top and exploded views, respectively, of an electrostatic chuck 100 designed to reduce wafer substrate "sticking" (increased from The difficulty with which the electrostatic chuck removes the wafer substrate) in order to "unclamp" or unclamp the wafer substrate from the electrostatic chuck after wafer substrate processing. Embodiments disclosed herein provide a conductive path on ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com