Tool for repairing flow passage of axial flow casing of aero-engine and application method for tool

An aero-engine and axial-flow technology, applied in the direction of injection devices, etc., can solve the problems affecting the performance parameters of the compressor and the out-of-tolerance of the inner flow path, etc., to achieve the effect of ensuring implementability, easy assembly, and improving spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

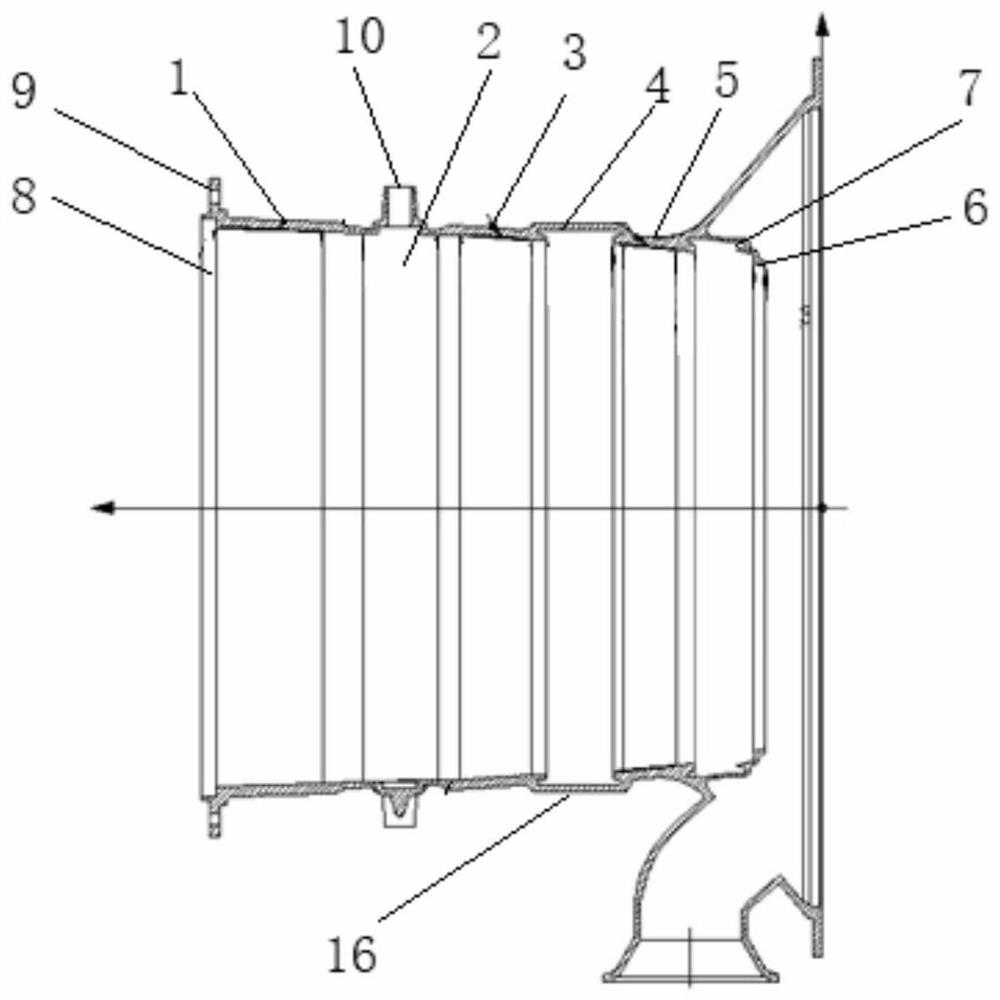

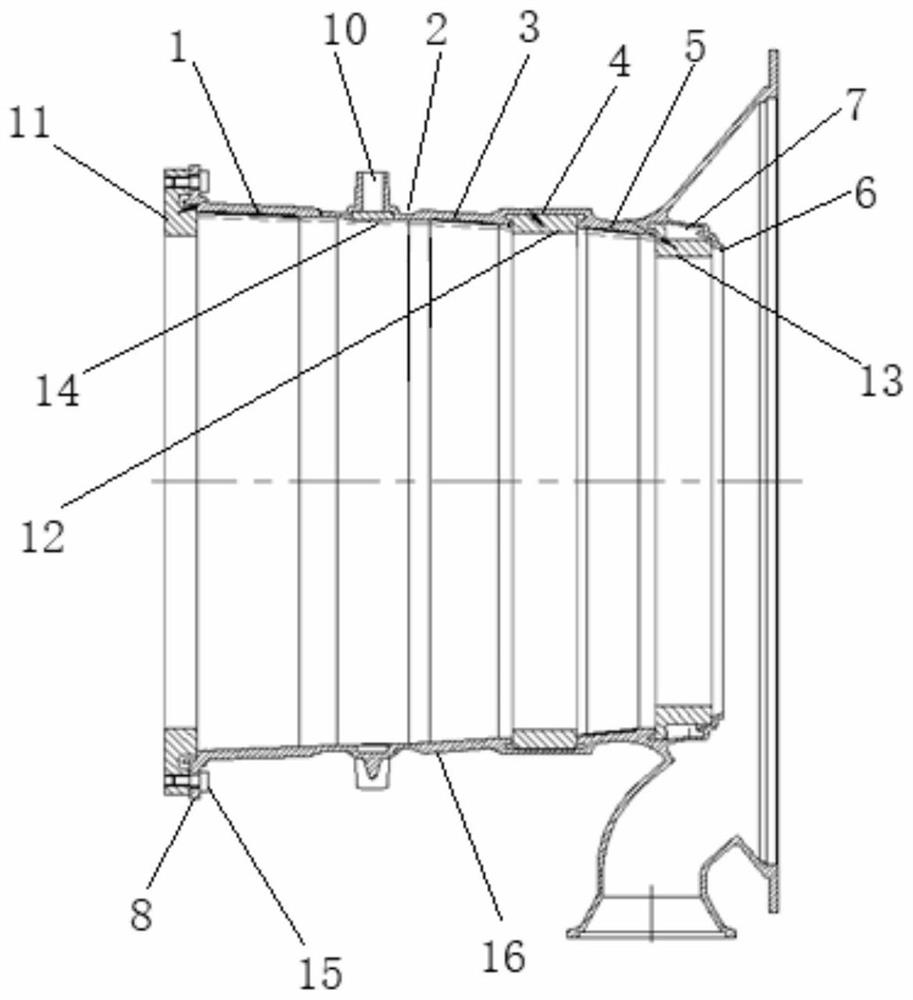

[0015] Such as Figure 1 to Figure 2 As shown, the tooling for repairing the flow path of the aero-engine axial flow casing in this embodiment includes the first protective ring 12 matching with the second-stage vane installation groove 4, and the first protection ring 12 matching with the third-stage vane installation groove 7. Two protective rings 13, spigot protective rings 11 and 30 plugs 14 that are compatible with the vane installation holes 10. The first protective ring 12 is composed of two first half-rings spliced together. The second protective ring 13 It is composed of two second half-rings spliced together; the outer wall of the first protection ring 12 fits with the inner wall of the second-stage stator vane installation groove 4 with a small gap, and the gap is less than 2.0mm; the outer wall of the second protection ring 13 and the third-stage stator vane The inner wall of the installation groove 7 fits with a small gap, and the gap is less than 2.0mm. The m...

Embodiment 2

[0018] The method of using the tooling for repairing the flow path of an aero-engine axial-flow casing includes the following steps: first, snap two first semi-annular bodies into the installation groove 4 of the second-stage vane, and connect the first semi-annular body with the second-stage vane Fill and apply 703 glue between the installation grooves 4, and form a circular first protective ring 12 from the first half ring body, snap the two second half ring bodies into the three-stage vane installation groove 7, and place them on the second half ring body. Fill and apply 703 glue between the ring body and the third-stage stationary vane installation groove 7, and form a circular second protective ring from the second half-annular body, and the outer wall of the second protective ring 13 and the third-stage stationary vane installation groove 7 The gap between the inner walls, the outer wall of the first protective ring 12 and the inner wall of the second-stage stationary van...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com