Transferring gripper mechanism for mounting automobile roof glass

A car roof and installation technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as time-consuming and laborious, glass damage, high work intensity, etc., to improve work efficiency, safety and stability Sexuality, the effect of reducing labor costs and work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

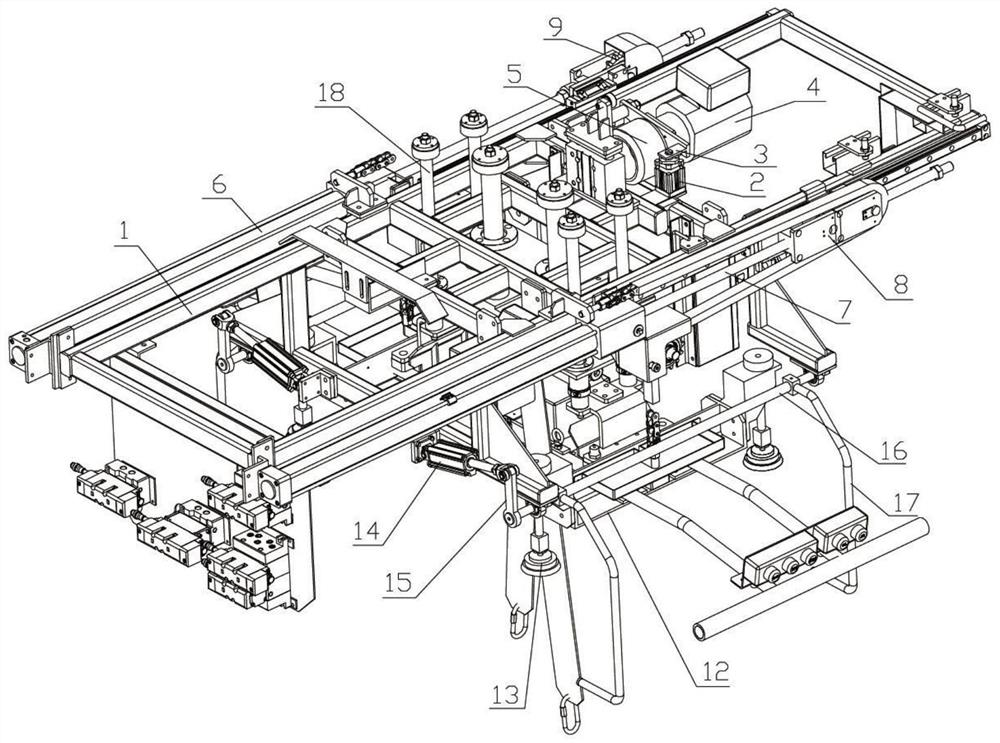

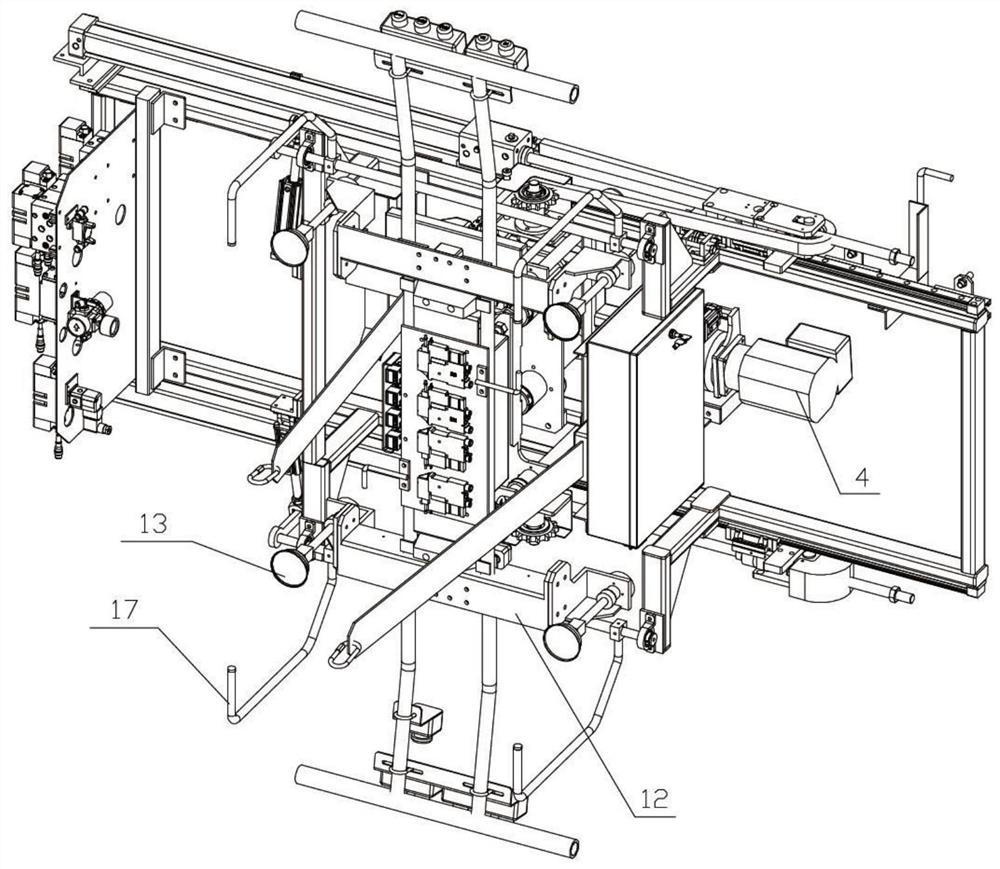

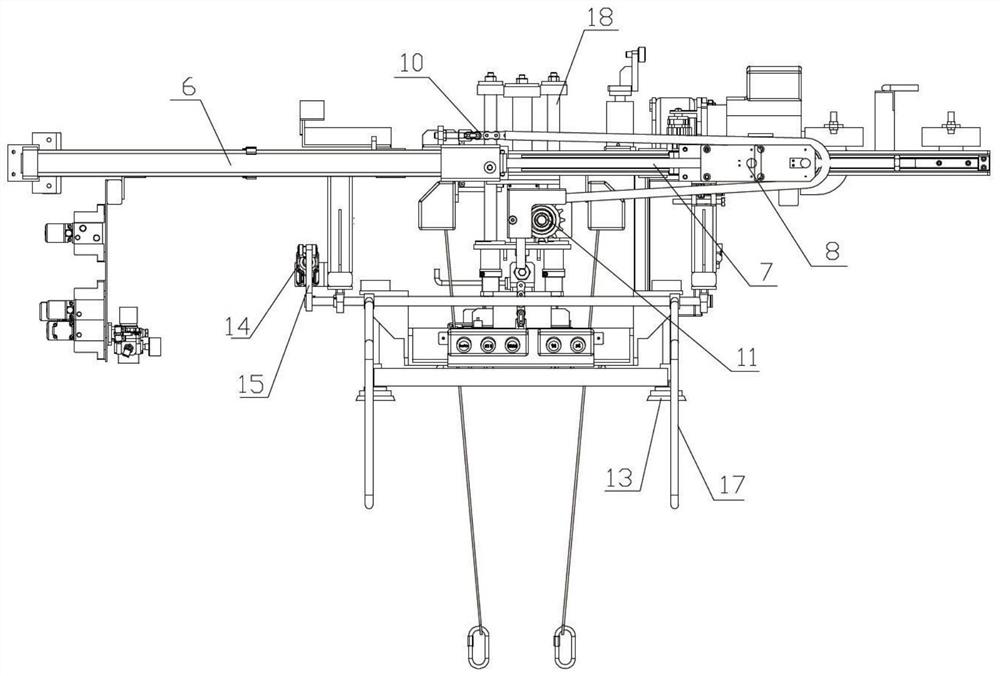

[0014] Attached below Figure 1-4 The present invention is described further:

[0015] A transfer handle mechanism for the installation of automobile roof glass, the frame 1 is fixed with a cylinder a2, the output end of the cylinder a2 is connected to the installation frame 3, the installation frame 3 is provided with a transfer drive motor 4, and the output of the transfer drive motor 4 The drive wheel 5 on the mounting frame 3 is connected to the drive wheel 5, the cylinder b6 is fixed on both sides of the frame 1, the output end of the cylinder b6 is connected to the push rod 7, the end of the push rod 7 is provided with a push block 8, and the connecting chain is rotated on the push block 8 Wheel a9, the frame 1 is provided with a sprocket b11, one end of the chain 10 is fixed on the frame 1, the chain 10 meshes with the sprocket a9 and the sprocket b11, the other end of the chain 10 is connected to the lifting frame 12, and the lifting frame 12 is fixed with a suction cu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap