Building formwork connecting structure for civil engineering

A technology of building formwork and civil engineering, which is applied in the direction of building construction, formwork/formwork/work frame connectors, construction components on-site preparation, etc., which can solve the inconvenience of connection, affect the effect of concrete pouring, and the spacing of building formwork Difficult to adjust and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

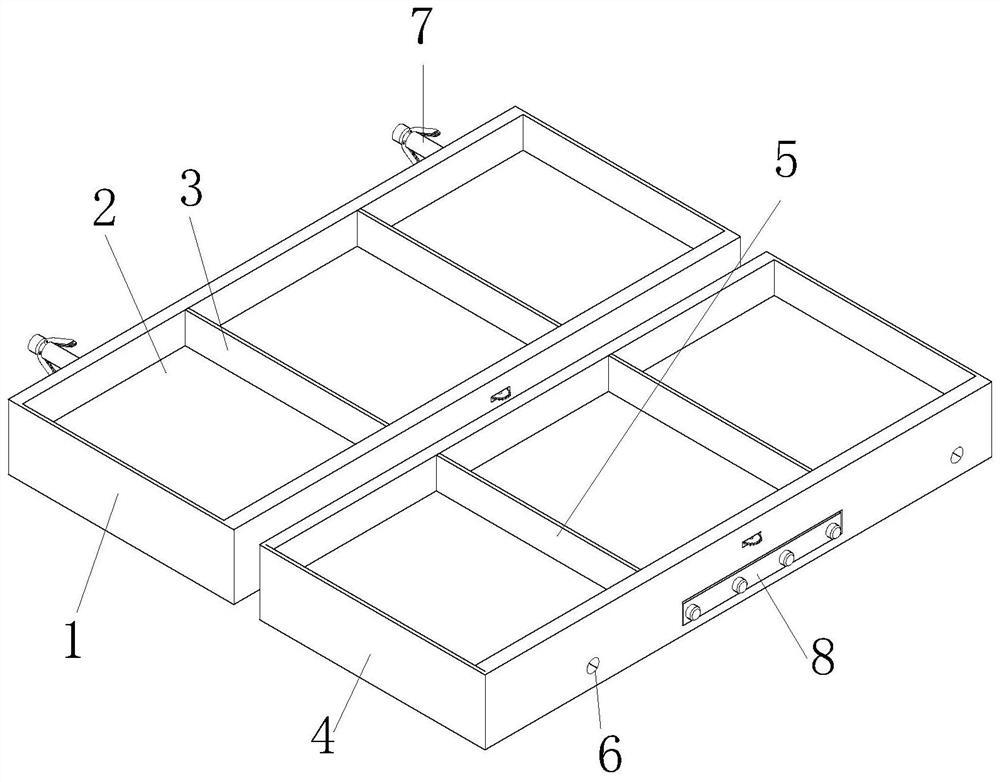

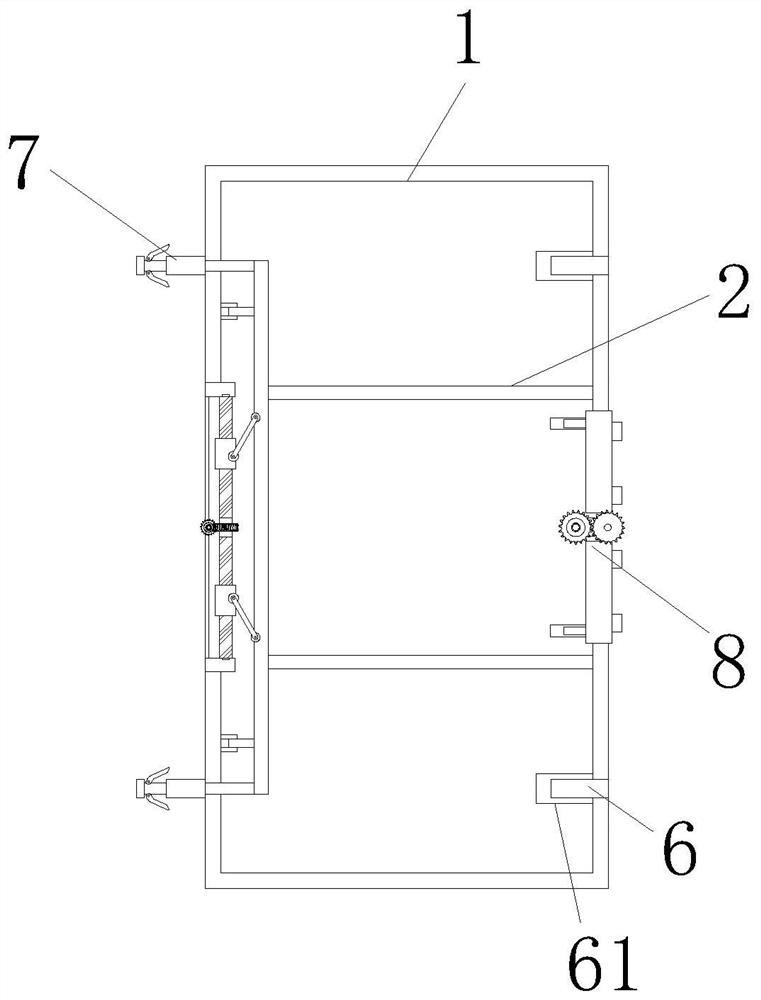

[0034] see figure 1 with figure 2 , the present invention provides a building formwork connection structure for civil engineering through improvement, including a first formwork body 1, a pouring groove 2, a first partition 3, a second formwork body 4, a second partition 5, and a slot 6 1. Connect the limiting mechanism 7 and the spacer supporting mechanism 8, the first formwork body 1 is provided with pouring grooves 2 inside, the pouring groove 2 is equidistantly distributed with first partitions 3, and the connecting limiting mechanism 7 is installed and fixed on the first formwork On the inner side of the left end of the body 1, the spacer support mechanism 8 is embedded and installed on the inner side of the right end of the second formwork body 4, the right end of the first formwork body 1 is provided with a second formwork body 4, and the second formwork body 4 is equidistantly distributed with second partitions 5 , slots 6 are provided on the front and rear sides of ...

Embodiment 2

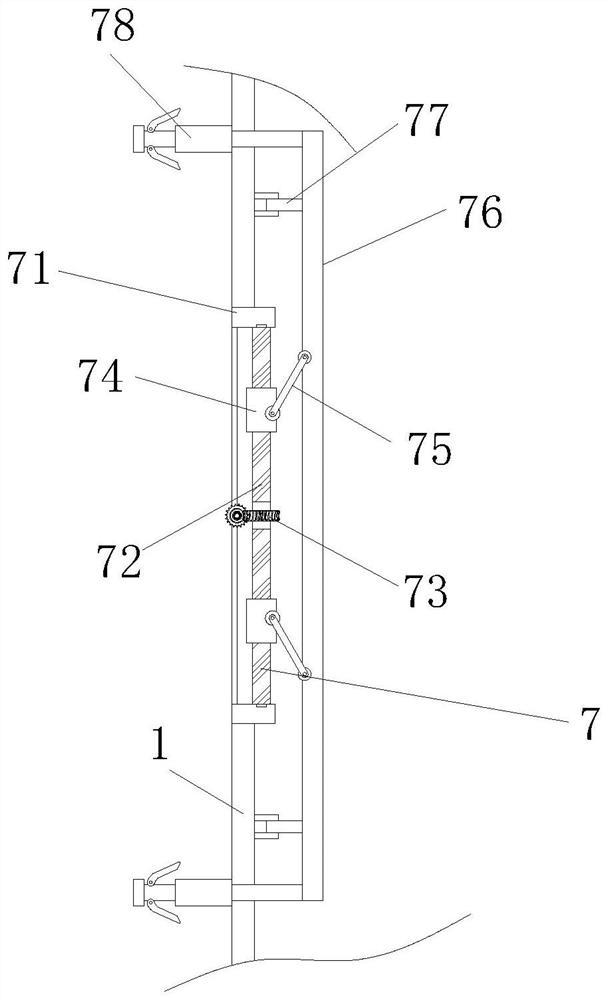

[0041] The present invention provides a building formwork connection structure for civil engineering through improvement. There are two limit rods 783, and damping hinges 7831 are arranged on the upper ends of the limit rods 783, which is beneficial to reset the limit rods 783. There are two sliders 74, and the sliders 74 are arranged oppositely along the front and rear sides of the screw rod 72. The upper ends of the two sliders 74 are provided with a swing rod 75, which is beneficial to push the push rod 76 to the right. Function, the slot 6 is provided with a card slot 61 inside.

[0042] The present invention provides a building formwork connection structure for civil engineering through improvement, and its working principle is as follows;

[0043] First, before use, the building formwork connection structure for civil engineering is placed horizontally, so that the first formwork body 1 and the second formwork body 4 support and fix the connection structure;

[0044] Se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com