Method for predicting vibration by gear microscopic errors based on neural network

A prediction method and neural network technology, applied in the field of gearboxes, can solve problems such as not using vibration prediction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

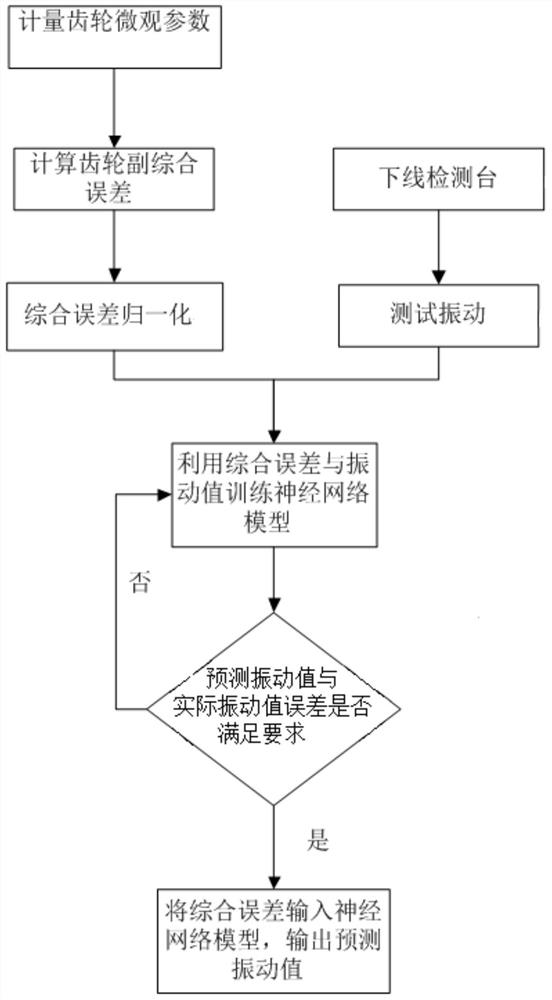

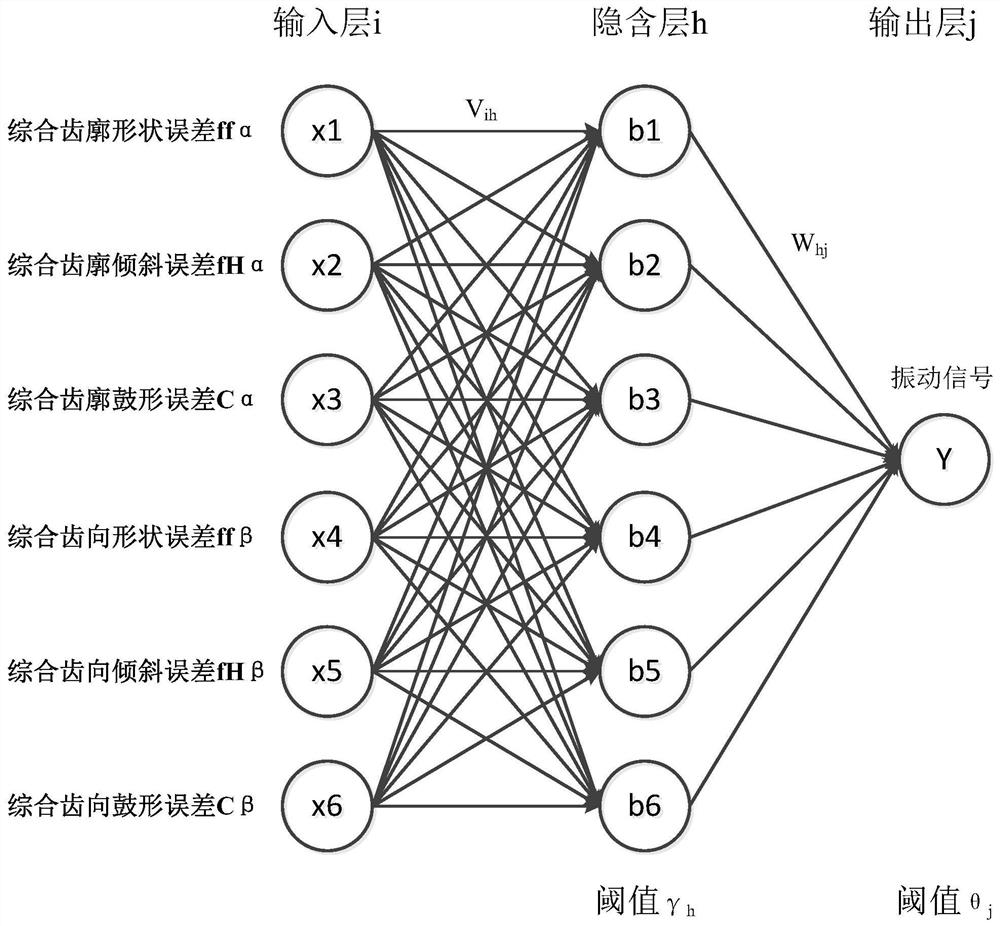

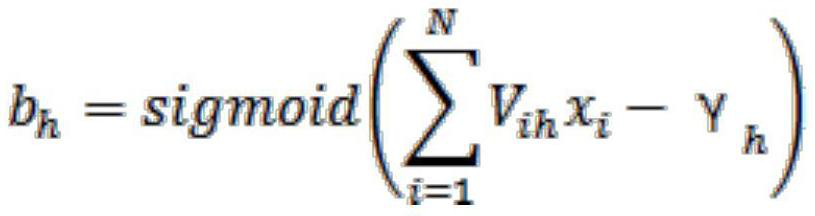

[0034] Embodiments of the present invention are described in detail below, see figure 1 with figure 2 , the embodiment of the present invention provides a neural network-based method for predicting vibration of gear microscopic errors, comprising the following steps:

[0035] Gear micro-errors of metering gearboxes;

[0036] Calculate the comprehensive error of the intermeshing gear pair of the gearbox according to the microscopic error of the gear;

[0037] Normalize each comprehensive error;

[0038] Test the vibration value of the gearbox;

[0039] Using the calculated comprehensive error of the intermeshing gear pair and the tested vibration value as training samples to train the established neural network model;

[0040] After the training of the neural network model is completed, calculate the comprehensive error of the intermeshing gear pair of the gearbox to be tested, input the newly calculated comprehensive error of the intermeshing gear pair of the gearbox into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com