Guide plate for digitally and accurately guiding support concave preparation process and manufacturing method thereof

A manufacturing method and a supporting concave technology, which are applied in the fields of medical science, dentistry, dental prosthesis, etc., can solve the problems of interfering with the patient's occlusal movement, violation, and weak force at the place of placement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment discloses a method for manufacturing a guide plate for digitally and accurately guiding the preparation process of the support recess, including the following steps:

[0041] A. Construct a digital oral model based on the patient's oral data.

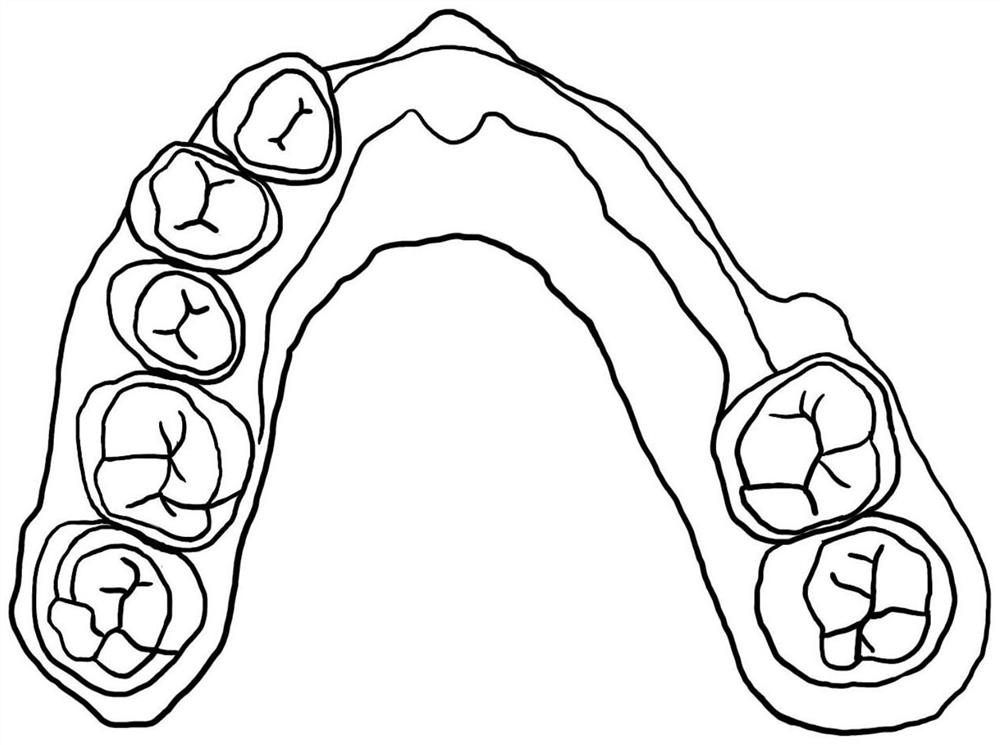

[0042] The patient's oral data can be obtained through an intraoral scanner or a desktop scanner after traditional impression taking. According to the obtained oral data, a corresponding digital oral model can be constructed using 3D modeling software. The construction of a digital oral model is as follows: figure 1 shown.

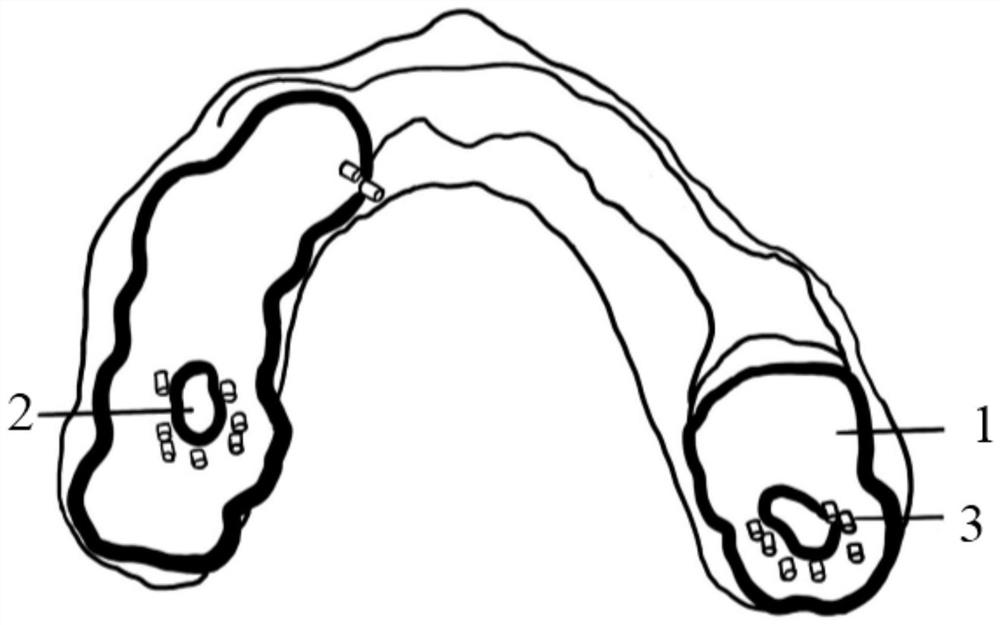

[0043] B. Prepare the rest recess 2 on the digital oral model.

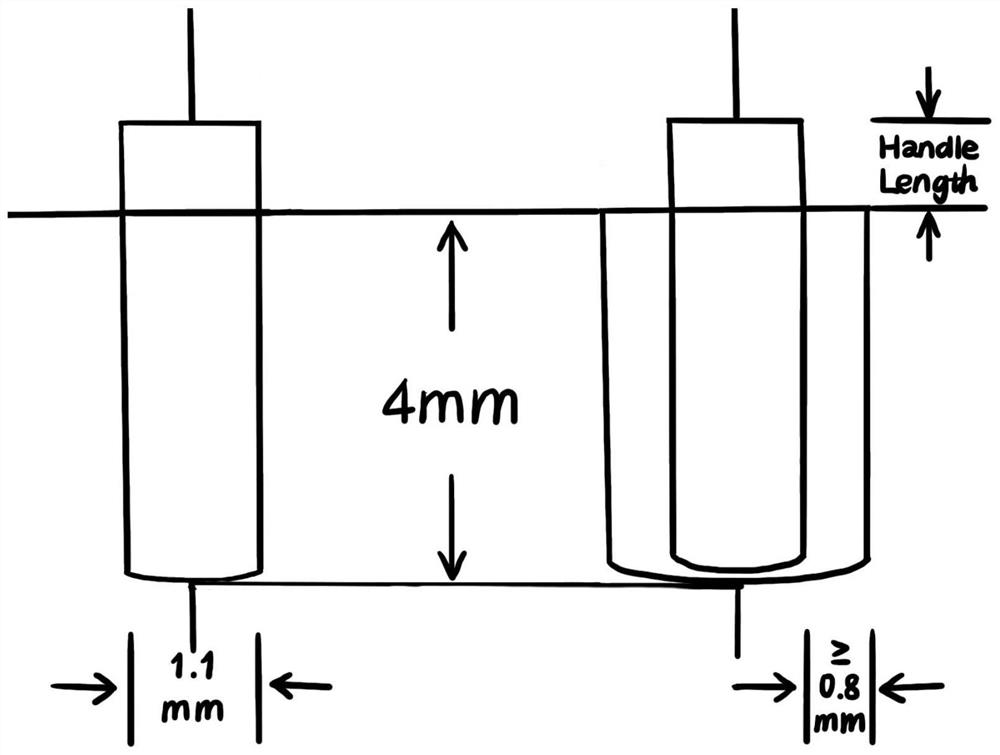

[0044] Import the patient's digital oral model into the professional oral restorative design software, and complete the support at the corresponding position in the software according to the minimum depth and standard range required for the cobalt-chromium alloy rest recess (there are corresponding specifications in the field of...

Embodiment 2

[0059] This embodiment discloses a guide plate for digitally and accurately guiding the preparation process of the support recess, which is made by the manufacturing method of the first embodiment above.

Embodiment 3

[0061] This embodiment discloses the use method of the guide plate (hereinafter referred to as the guide guide plate) for digitally and accurately guiding the preparation process of the support recess in the second embodiment, including:

[0062] A. Position the positioning guide in the patient's mouth.

[0063] B. Fix a group of preparatory plug-in entities to the retaining post 3 of the positioning guide plate through their support columns. Under the guidance of the guide rings of the preparatory plug-in entities, the physician uses a matching preparatory bur (usually select a preparatory bur with scale) ) Prepare the rest recess on the area reserved on the positioning guide. Every time a group of support recesses 2 is prepared, the preparatory plug-in entity is replaced, and the next set of support recesses 2 is prepared, and the cycle is repeated until all support recesses 2 are prepared, such as Figure 7 shown.

[0064] C. Remove (the last group) the preparatory plug-i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com