High-strength recycled fine aggregate anti-crack concrete preparation method

A recycled fine aggregate, high-strength technology, applied in grain processing, etc., can solve problems such as equipment winding, tool position cannot be changed, machine jamming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

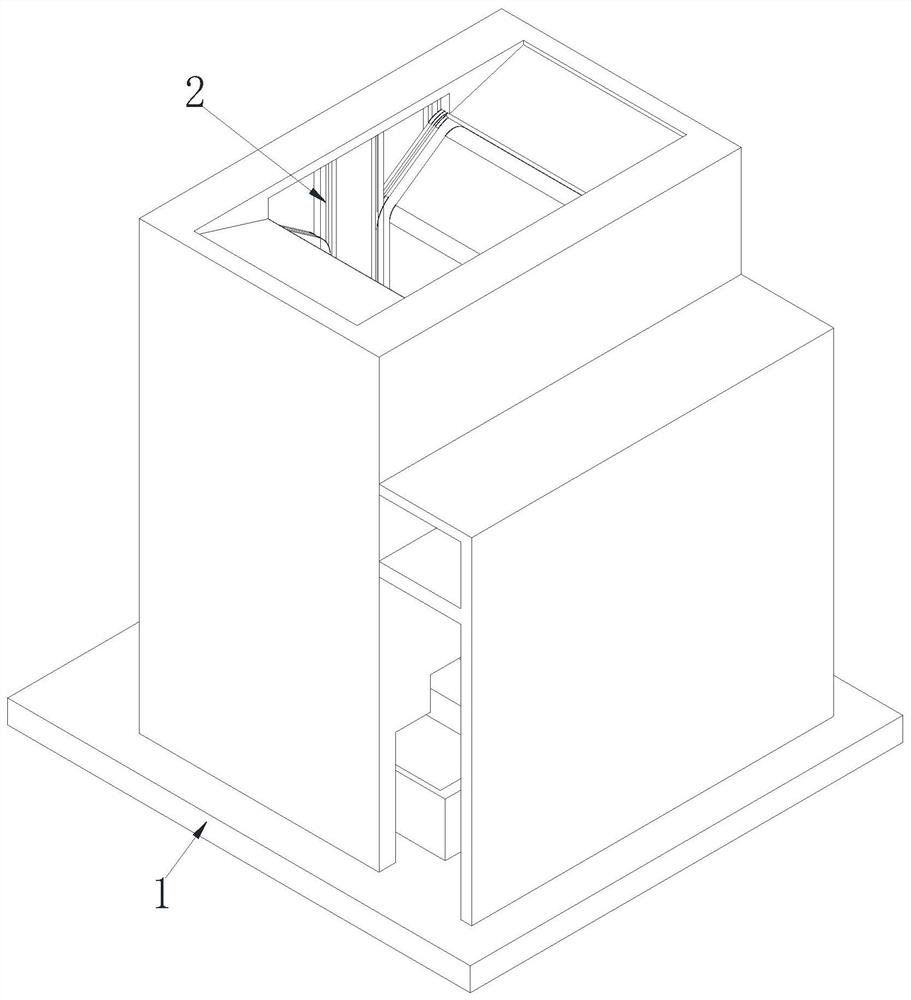

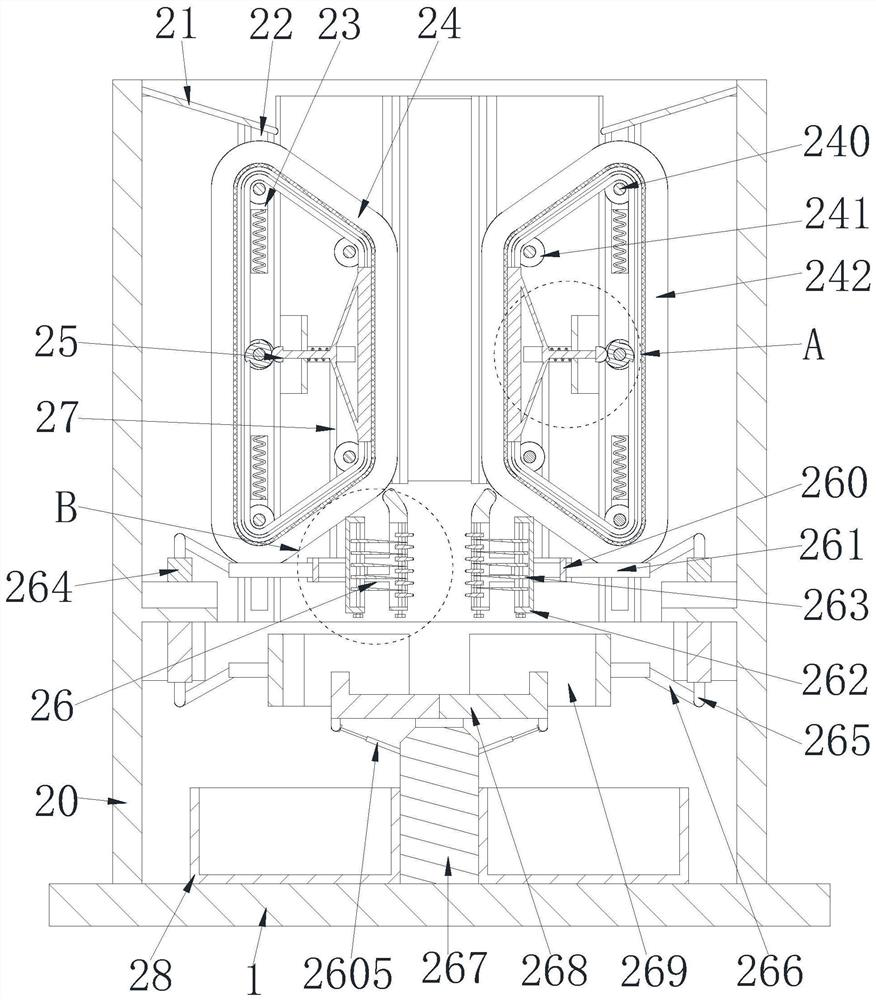

[0035] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 8 , to further elaborate the present invention.

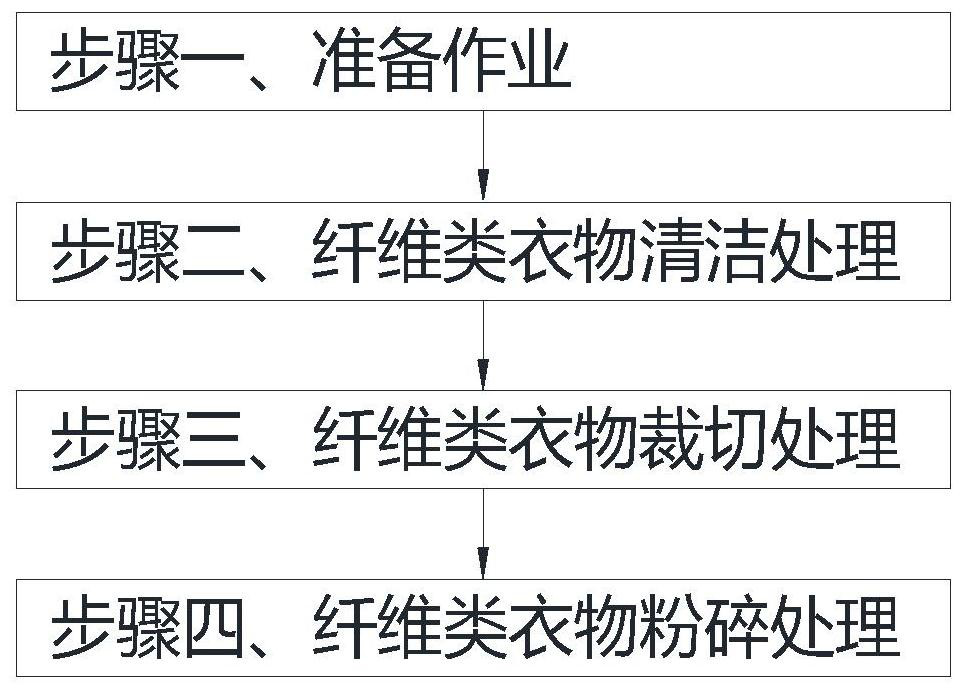

[0036] A method for preparing high-strength recycled fine aggregate anti-crack concrete, which uses a high-strength recycled fine aggregate anti-crack concrete preparation equipment, the high-strength recycled fine aggregate anti-crack concrete preparation equipment includes a base 1 and a cutting device 2. Using the above-mentioned high-strength recycled fine aggregate anti-crack concrete preparation equipment to cut high-strength recycled fine aggregate anti-crack concrete fiber clothing raw materials, the specific method is as follows:

[0037] Step 1. Preparatory work: debugging the high-strength recycled fine aggregate anti-crack concrete preparation equipment of the present invention;

[0038] Step 2. Cleaning treatment of fibrous clothing: f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com