Full-automatic cabbage mashing device for poultry feeding

A fully automatic, cabbage technology, applied in application, food processing, food science, etc., can solve problems such as slow cutting speed of cabbage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of automatic crushing device for cabbage for poultry feeding, such as figure 1 As shown, it includes a bottom plate 1, a base 2, a water-filling frame 21, a servo motor 3, a crushing mechanism 4, and a feeding mechanism 5. The base plate 1 is provided with a base 2 on the rear side of the upper part, and a water-filling frame 21 is arranged in the middle of the bottom plate 1 top. , The inner top of the base 2 is provided with a servo motor 3, the upper left side of the bottom plate 1 is provided with a crushing mechanism 4, and the crushing mechanism 4 is provided with a feeding mechanism 5.

[0028] When the user needs to chop the cabbage, the device can be used. First, the cabbage to be chopped is placed in the feeding mechanism 5, and then the servo motor 3 is started, and the components of the crushing mechanism 4 are driven by the servo motor 3. Movement, the cabbage is chopped by the crushing mechanism 4, and the chopped cabbage can fall down in the water-...

Embodiment 2

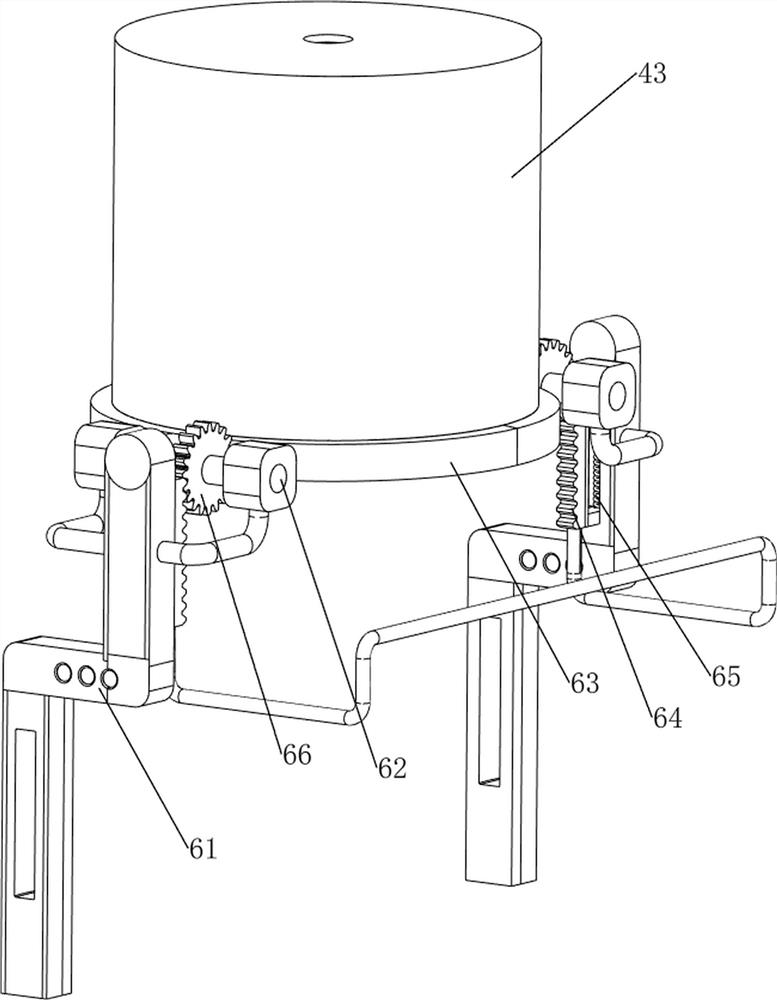

[0030] On the basis of Example 1, such as Figure 2-4 As shown, the crushing mechanism 4 includes a first support frame 41, a support frame 42, a crushing barrel 43 and a crushing knife 44. A support frame 42 is provided, and a crushing barrel 43 is arranged in the support frame 42 , and a crushing knife 44 is connected to the output shaft of the servo motor 3 .

[0031] When the cabbage is fed into the crushing barrel 43, the servo motor 3 drives the crushing knife 44 to rotate, so that the crushing knife 44 can cut the cabbage, and the user can place a pallet on the bottom of the crushing barrel 43 to crush the cabbage The cabbage will be collected on the top of the tray.

[0032] The blanking mechanism 5 includes a blanking tube 51, a blanking tube 52 and a baffle plate 53, the first support frame 41 top is provided with a blanking tube 51, the left side of the crushing bucket 43 is connected with a blanking tube 52, and the blanking tube 52 is connected with the lower ma...

Embodiment 3

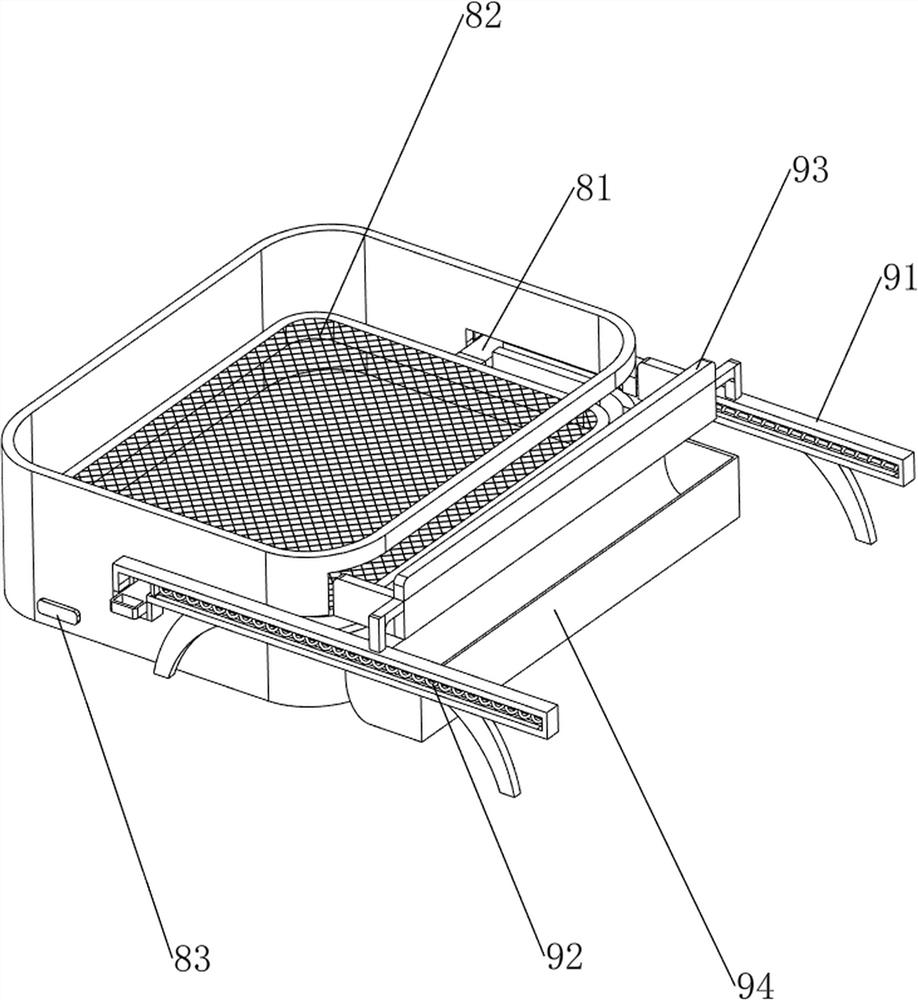

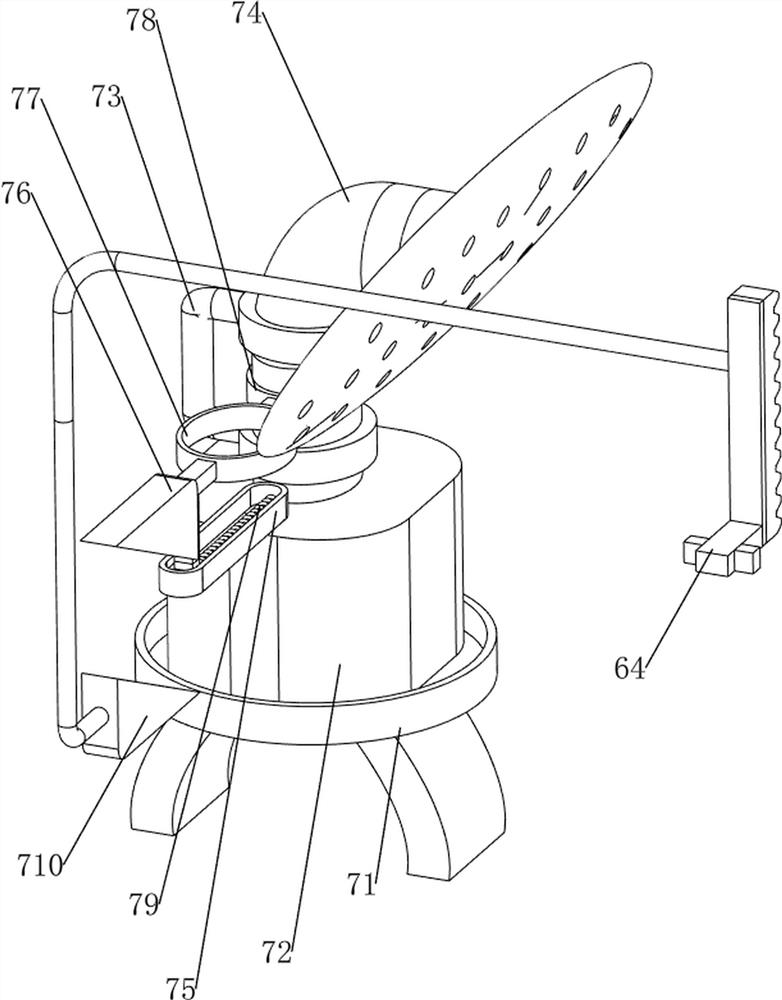

[0035] On the basis of Example 2, such as Figure 5-6 As shown, it also includes an unloading mechanism 6. The unloading mechanism 6 includes a second support frame 61, a rotating shaft 62, a rotating plate 63, a rack 64, a first spring 65 and a gear 66; There is a second support frame 61, and the second support frame 61 is equipped with a rotating shaft 62 in a rotating manner. A rack 64 is provided, and the racks 64 on both sides are connected by connecting rods, a first spring 65 is connected between the rack 64 and the second support frame 61, and a gear 66 is arranged on the rotating shaft 62, and the gear 66 meshes with the rack 64 .

[0036] The user can hold the connecting rod to move upwards, and then drive the racks 64 on both sides to move upwards, and the racks 64 are engaged with the gears 66 to drive the rotating shaft 62 and the rotating plate 63 to rotate, thereby crushing the crushed bags in the bucket 43 The dish will fall down into the water-filling frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com