Equipment capable of realizing cover opening and closing of box

A box and equipment technology, applied in the field of equipment that can realize the opening and closing of the box, can solve the problems of limited work efficiency, inability to take out conveyor belt workpieces, limited number of pick-and-place workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

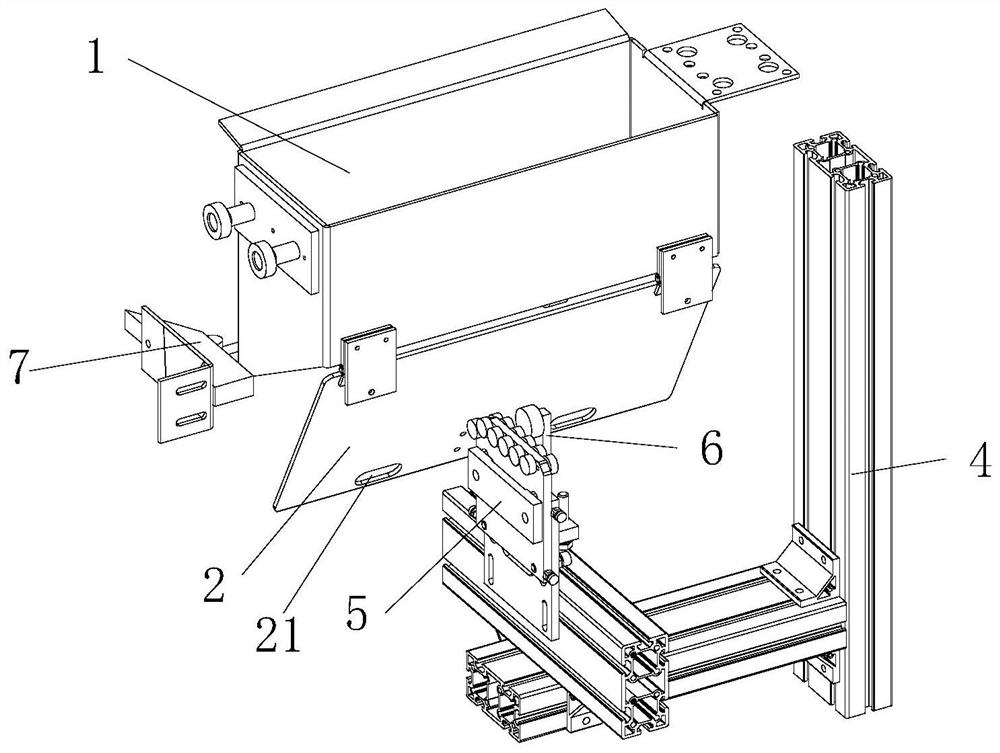

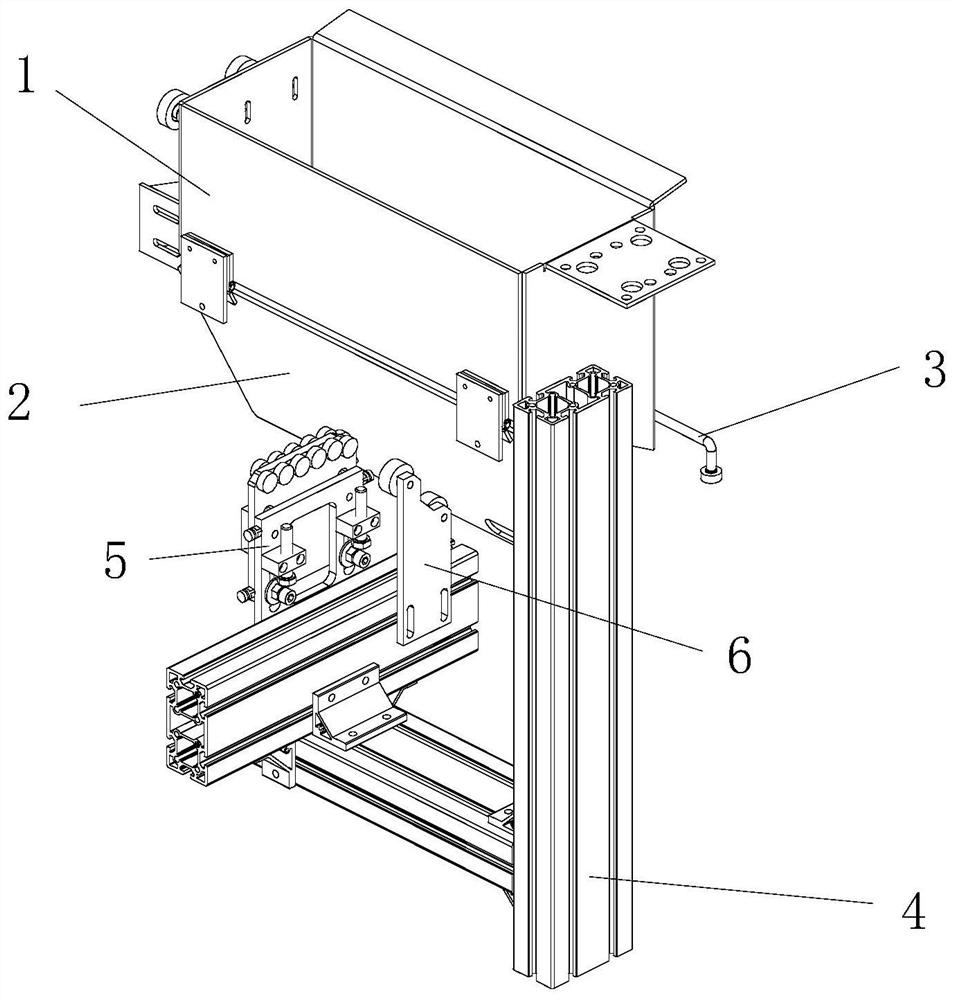

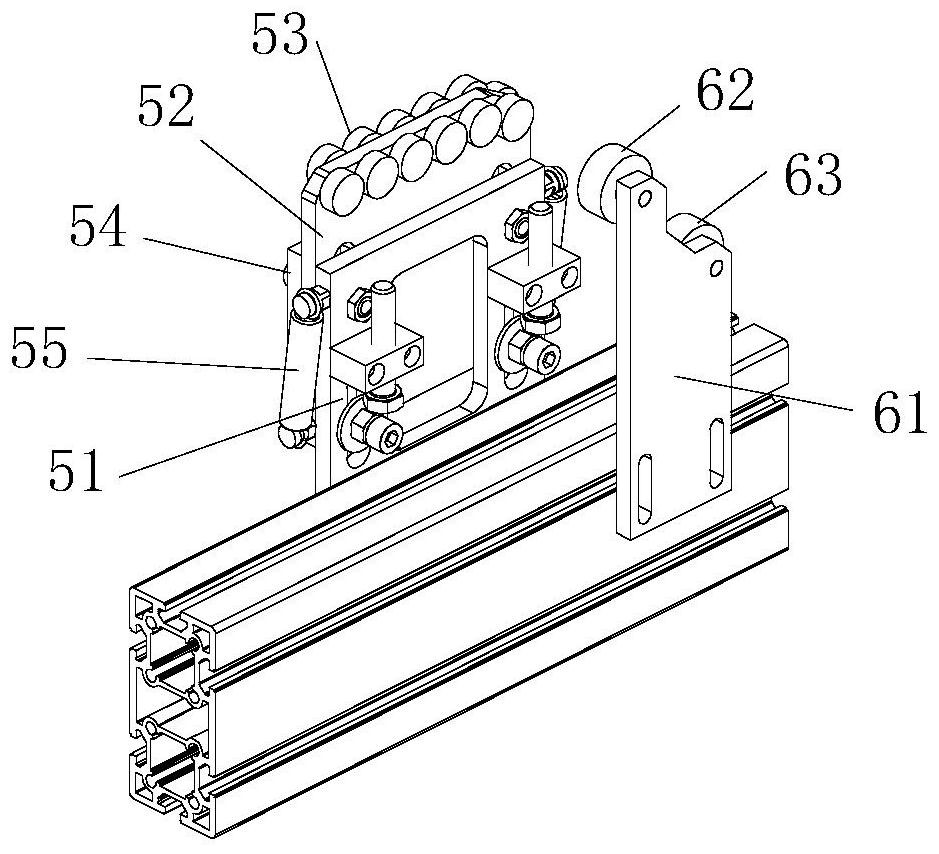

[0036] Such as Figure 1 to Figure 5 As shown, the present embodiment is a device that can realize the opening and closing of the box, including the box, the opening mechanism 8 and the closing mechanism.

[0037] The box body includes a box body 1 provided with an accommodating cavity, and a lower flip cover 2 hinged at the lower end of the box body 1 and opened and closed under the accommodating cavity. The lower end of the box body 1 is inclined downward when extending from one end hinged with the lower flap 2 to the other side.

[0038] In the closed state, the lower flap 2 protrudes from the box body 1 at the end far away from the hinged part of the box body 1 to form a locking area; the locking area is provided with two latch elongated holes 21; in this embodiment There are two bolt elongated holes, and in practical applications, there can be one, three, four, or even more bolt elongated holes.

[0039] The box body 1 is provided with a movable locking bar 3 near the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com