Zero-discharge treatment device for medical blood sewage

A treatment device and zero discharge technology, which is applied in the direction of heating water/sewage treatment, oxidized water/sewage treatment, multi-stage water/sewage treatment, etc., can solve the treatment requirements that cannot meet zero discharge, and cannot meet the advanced treatment of pathogenic microorganisms And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

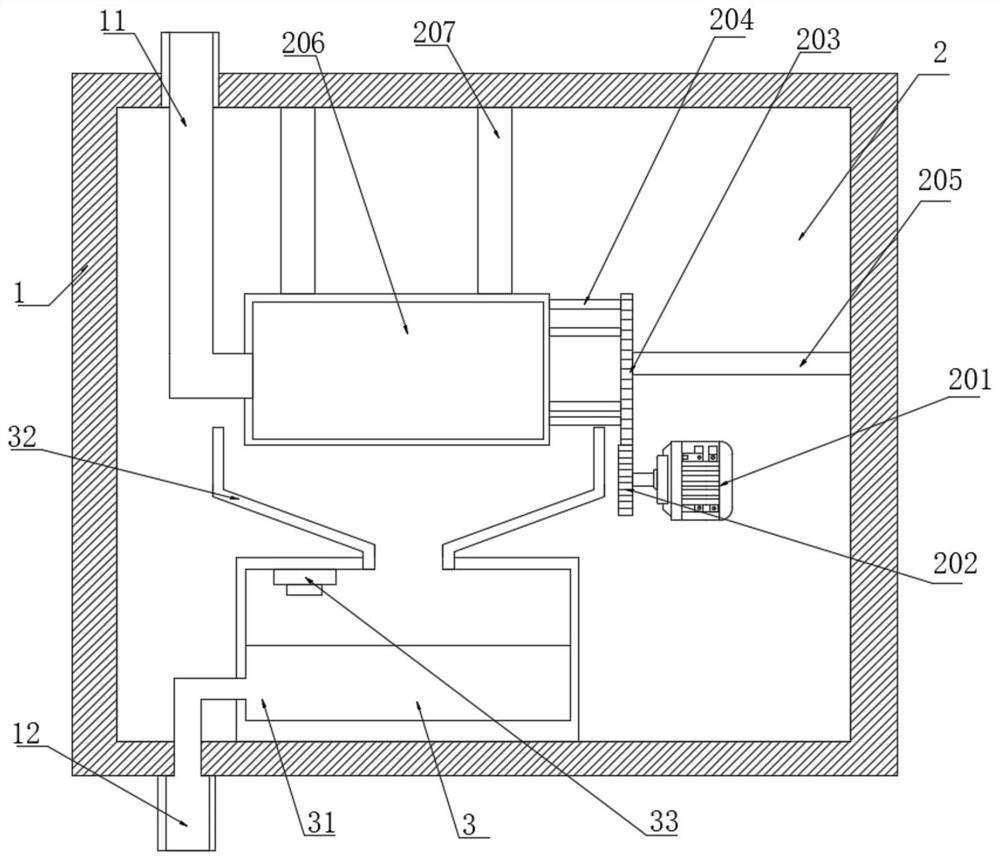

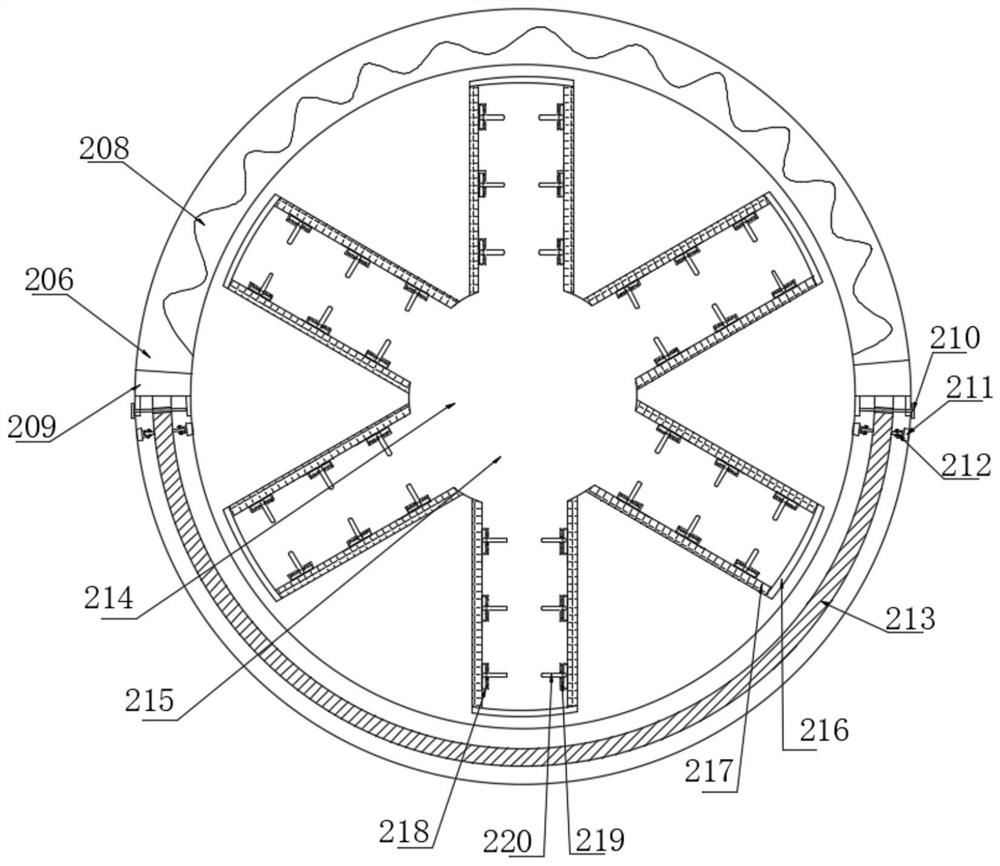

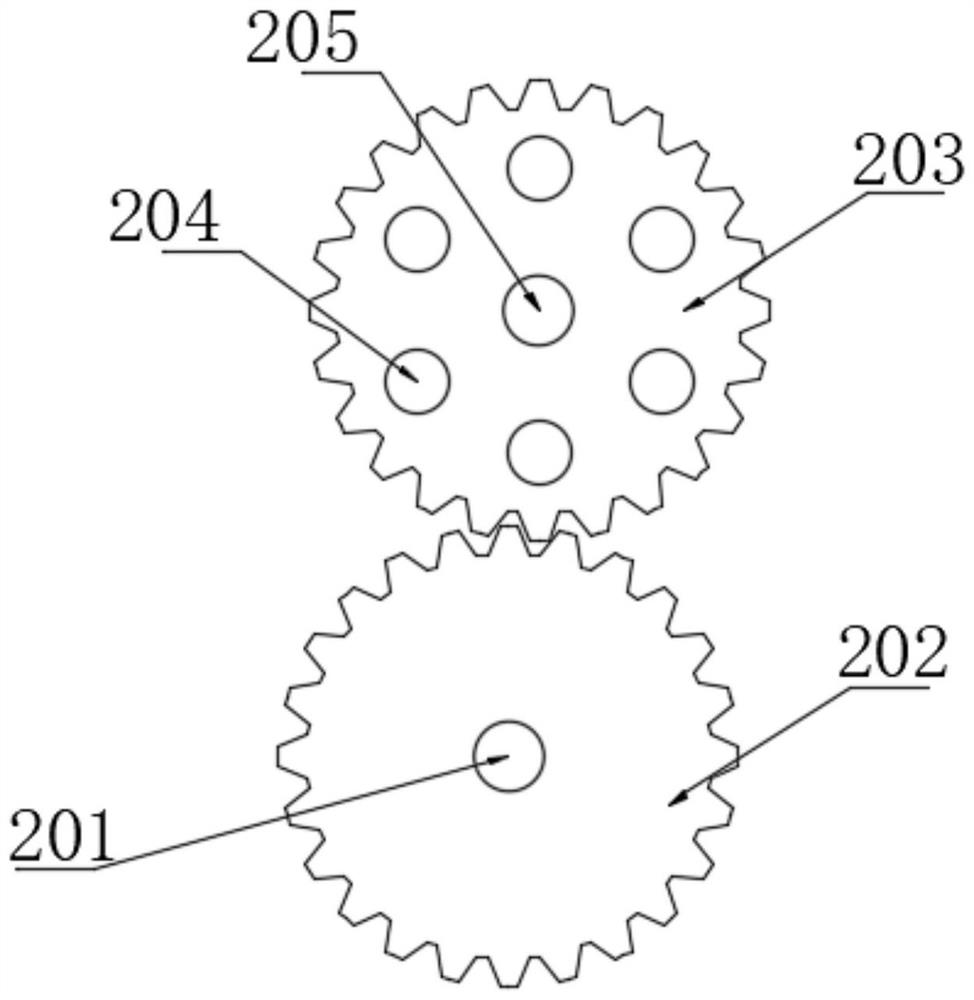

[0026] Such as Figure 1-5 As shown, a medical bloody sewage zero-discharge treatment device includes a housing 1, a water inlet pipe 11 is fixedly installed on the top surface of the housing 1, an outlet pipe 12 is fixedly installed on the bottom surface of the housing 1, and the inner cavity of the housing 1 is fixed A first-level processing mechanism 2 is installed, and the first-level processing mechanism 2 includes a motor 201. The output shaft of the motor 201 is fixedly sleeved with a first transmission gear 202, and the tooth surface of the first transmission gear 202 is meshed with a second transmission gear 203. The surface of the transmission gear 203 is fixedly installed with a connecting rod 204, and the shaft center of the second transmission gear 203 is fixedly sleeved with a mounting rod 205, and the end of the connecting rod 204 away from the second transmission gear 203 is fixedly connected with a primary treatment chamber 206. A fixed rod 207 is fixedly inst...

Embodiment 2

[0036] Such as Figure 6 As shown, the difference between the present embodiment and Embodiment 1 is: the side of the secondary treatment chamber 31 is fixedly equipped with an ozone generator 34, and the top surface of the ozone generator 34 is fixedly connected with an air inlet pipe 35, and the air inlet pipe 35 is away from the ozone One end of generator 34 is fixedly connected with shower head 36, and shower head 36 is fixedly installed on the inner cavity top surface of secondary treatment chamber 31, produces ozone through air inlet pipe 35, shower head 36 to the inner cavity of secondary treatment room 31 by ozone generator 34 The sewage is sterilized at a deep level, so as to completely remove the source of pathogens and prevent infectious bacteria from lurking in the sewage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com