Thermal management system and thermal management control method of a hydrogen refueling station

A technology of a thermal management system and a control method, applied in the field of hydrogen refueling station equipment, can solve the problems of increasing the energy consumption and cost of thermal management of the hydrogen refueling station, comprehensive design and control of the thermal management system, redundant configuration of thermal management equipment, etc. Conducive to the promotion of use, reducing safety hazards, reducing energy consumption and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

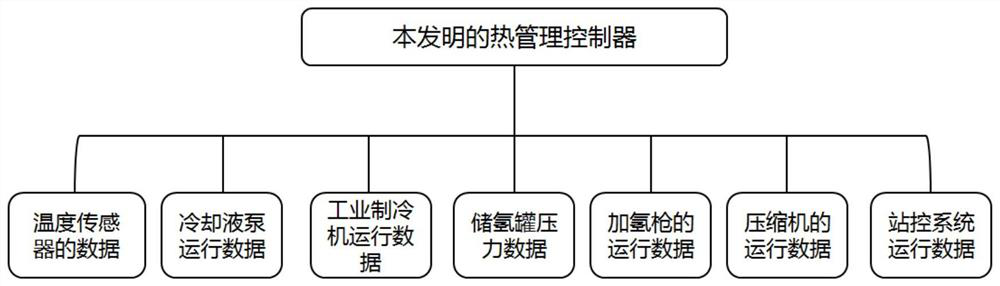

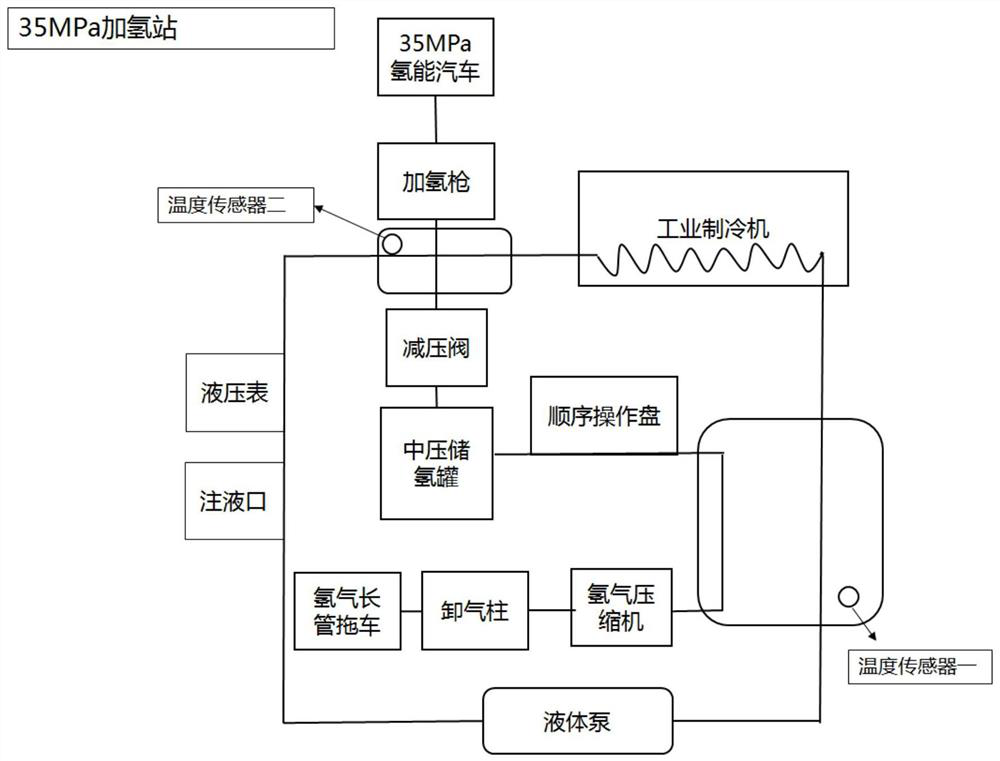

[0083] A thermal management control method of a hydrogen refueling station, applied to the above-mentioned thermal management system of a hydrogen refueling station, which includes the following content:

[0084] The first step is to establish a refrigeration model about the relationship between temperature and cooling liquid pump speed and industrial refrigerator power regulation;

[0085] The second step is to obtain the hydrogen temperature value 1 at the outlet of the compressor and the hydrogen temperature value 2 at the outlet of the hydrogen pressure reducing valve in real time

[0086] The third step is to input the hydrogen temperature value 1 and / or the hydrogen temperature value 2 into the refrigeration model to obtain the adjustment data;

[0087] The fourth step is to dynamically adjust the speed of the coolant pump and the cooling power of the industrial refrigerator according to the adjustment data to control the flow speed and temperature of the coolant.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com