Metal material welding-rolling integrated composite forming method

A metal material and composite forming technology, applied in the field of material engineering, to achieve the effect of expanding the range of welding and rolling process parameters, solving softening problems, and improving softening problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 1.5mm thick 6061-T6 aluminum alloy welding and rolling compound forming example

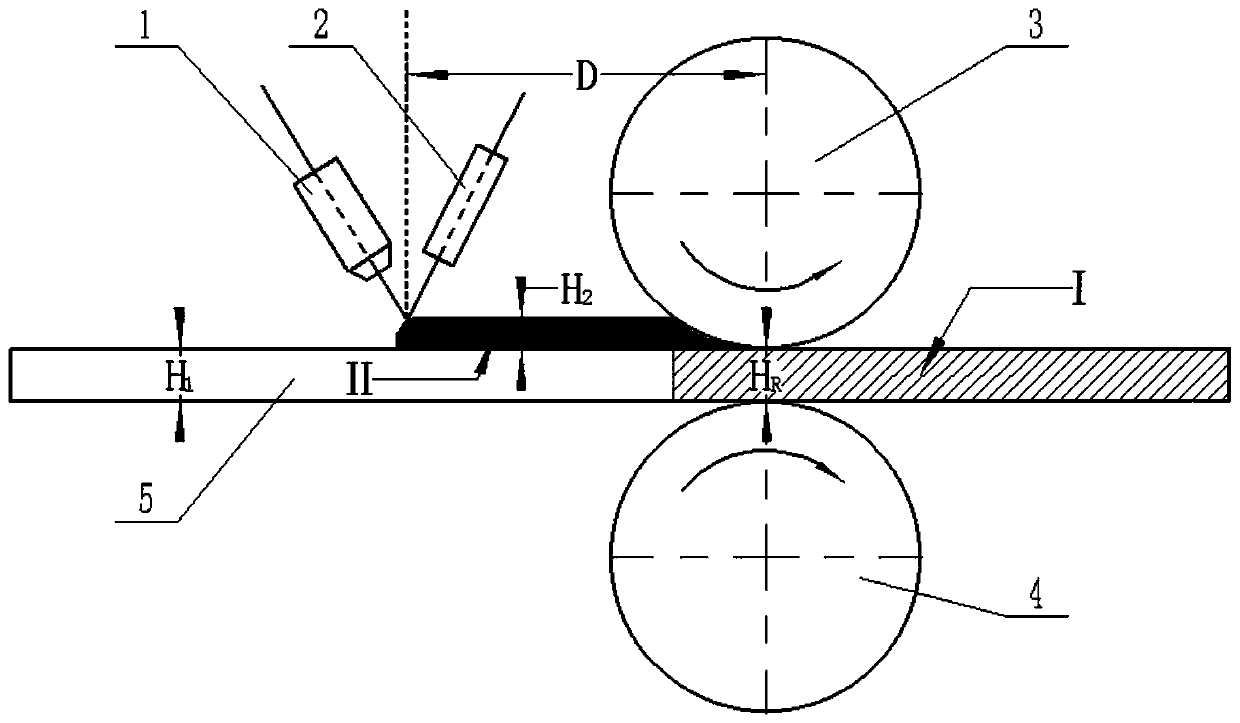

[0041] Such as figure 1 As shown, a double-roll rolling device is used to implement welding-rolling composite forming. In the figure, 1 is a wire feeder; 2 is a welding gun; 3 is an upper roll; 4 is a lower roll.

[0042] Welding object is plate thickness H 1 = 1.5mm 6061-T6 aluminum alloy (that is, the metal material 5 is implemented in the figure), and the size of the test plate is 100mm×50mm×1.5mm. The welding heat source (welding gun 2) adopts laser-tungsten argon arc (TIG) filler wire butt hybrid welding heat source. The main welding parameters are: YAG pulse laser average power 900W, tungsten argon arc welding welding current 100A, tungsten electrode height 2mm, welding Speed 600mm / min, wire feeding speed 6500mm / min, welding wire grade is ER5356, wire feeding angle 20°, welding joint residual height H 2 Is 2.0mm, the distance between the laser action point and the roll is D=2...

Embodiment 2

[0044] Example 2 Composite forming example of 2.5mm thick 5083-O aluminum alloy sheet and 2.5mm thick 6061-T6 aluminum alloy sheet

[0045] The welding objects are 5083-O aluminum alloy plate and 6061-T6 aluminum alloy plate with plate thickness H1=2.5mm. The size of the test plate is 200mm×100mm×2.5mm. The welding heat source adopts cold metal transition arc (CMT) welding heat source. The main welding parameters are: cold metal transition arc current 120A, arc voltage 14.8V, welding speed 550mm / min, wire feeding speed 8000mm / min, welding wire grade is ER5356, after welding Welding joint residual height H 2 Is 2.4mm, the distance between the arc welding torch and the roller is D=200mm, and the distance between the two rollers of the rolling process is H R =2.5mm.

[0046] Using the above-mentioned welding-rolling composite forming method, the tensile strength of the obtained butt-joined specimen can reach 100% of the 5083-O base metal and more than 90% of the 6061-T6 base metal; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com