Pouch film, pouch-type battery case, and pouch-type secondary battery

A battery case and pouch-type technology, which is applied in the direction of lithium batteries, battery pack parts, battery boxes/coatings, etc., can solve problems such as limitations, reduced volumetric energy efficiency of secondary batteries, and reduced electrode assembly size, etc., to achieve Effect of improving tensile strength and elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

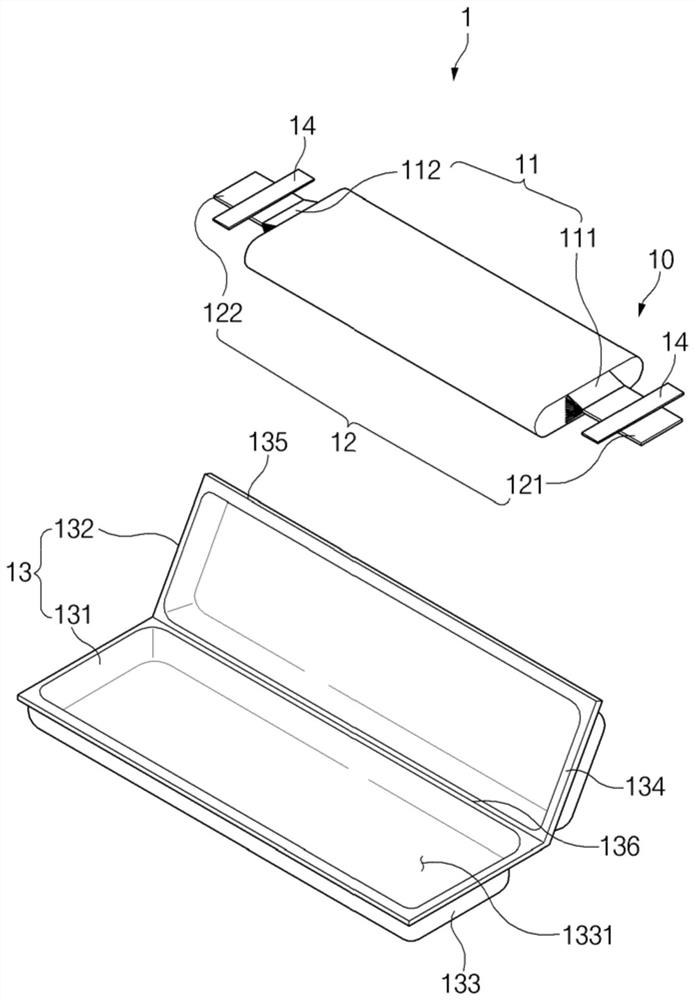

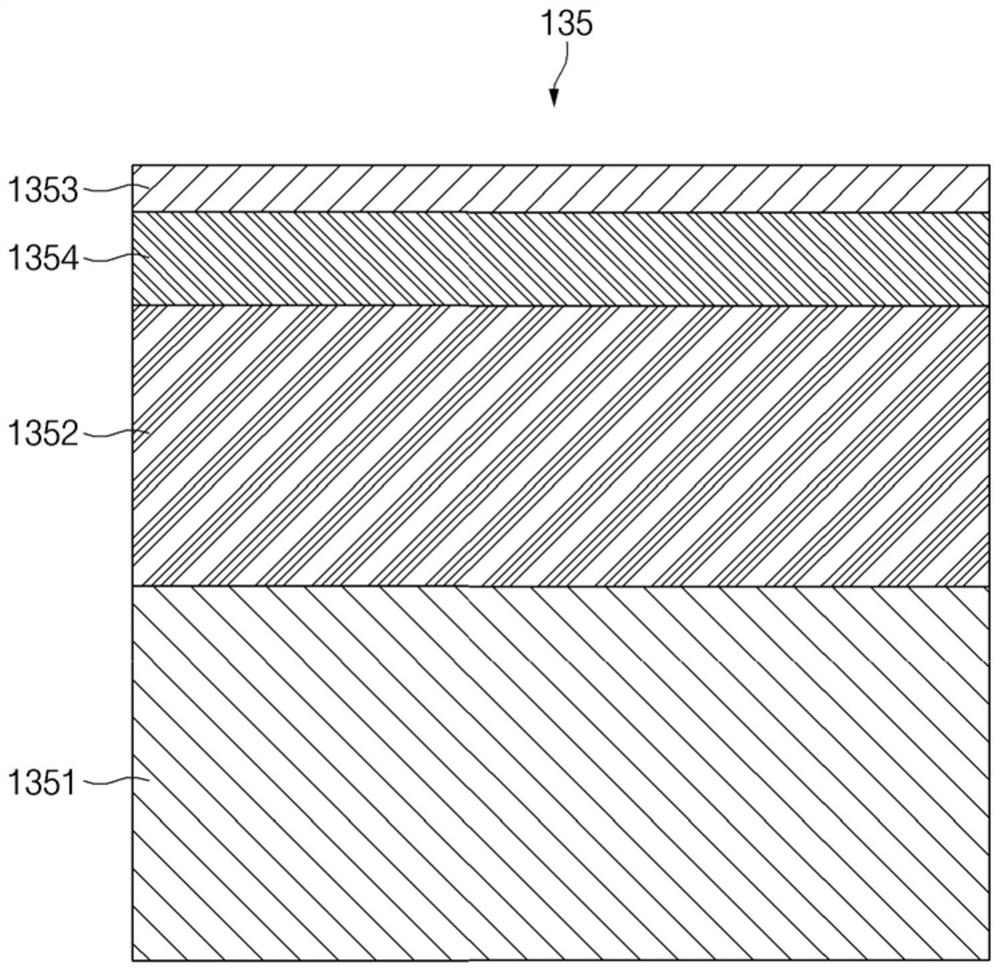

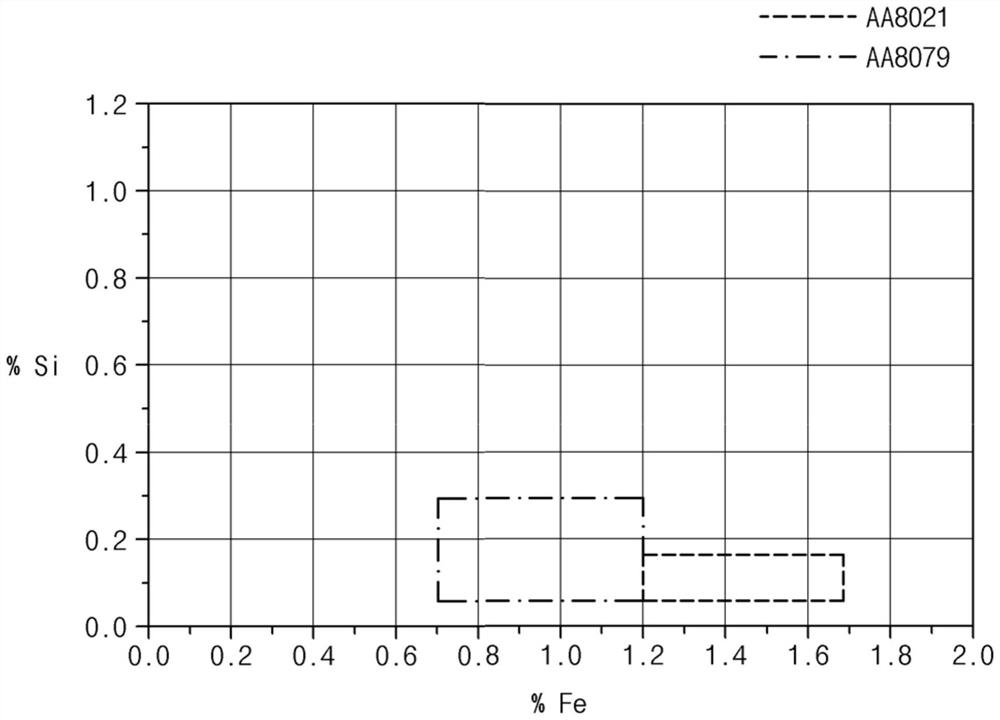

[0086]A nylon resin with a width of 266 cm, a length of 50 m, and a thickness of 25 μm and a polyethylene terephthalate (PET) with a width of 266 cm, a length of 50 m, and a thickness of 12 μm were sequentially laminated on a surface with a width of 266 cm and a length of 266 cm. 50m, 60μm thick on one surface of AA8021 aluminum (Al) alloy, and laminated cast polypropylene (CPP) with a width of 266cm, length 50m, and 80μm thickness on the other surface of AA8021 aluminum (Al) alloy On the surface.

[0087] In this paper, nylon and aluminum (Al) alloys were bonded to each other by dry lamination using conventional polyurethane adhesives, and cast polypropylene (CPP), which has excellent electrolyte resistance, was melted at high temperature, and then This was coextruded and laminated on an aluminum (Al) alloy to manufacture a bag film according to a production example of the present invention. In this paper, aluminum (Al) alloy forms the gas barrier layer, PET forms the surfac...

manufacture example 2

[0089] A bag film was produced in the same manner as in Production Example 1, except that the nylon resin had a thickness of 30 μm and the polyethylene terephthalate (PET) had a thickness of 7 μm. According to Production Example 2, the thickness ratio of the stretching auxiliary layer to the gas barrier layer was 1:2.

manufacture example 3

[0091] A bag film was produced in the same manner as in Production Example 1, except that the nylon resin had a thickness of 25 μm and the polyethylene terephthalate (PET) had a thickness of 7 μm. According to Production Example 3, the thickness ratio of the stretching auxiliary layer to the gas barrier layer was 1:2.4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com