Preparation method of glue for PET insulating sleeve

An insulating sleeve and internal mixer technology, applied in the field of industrial rubber, can solve the problems of no breakthrough in tensile strength and elongation, limited tensile strength and elongation of insulating sleeves, etc., and achieve tensile strength. and elongation improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

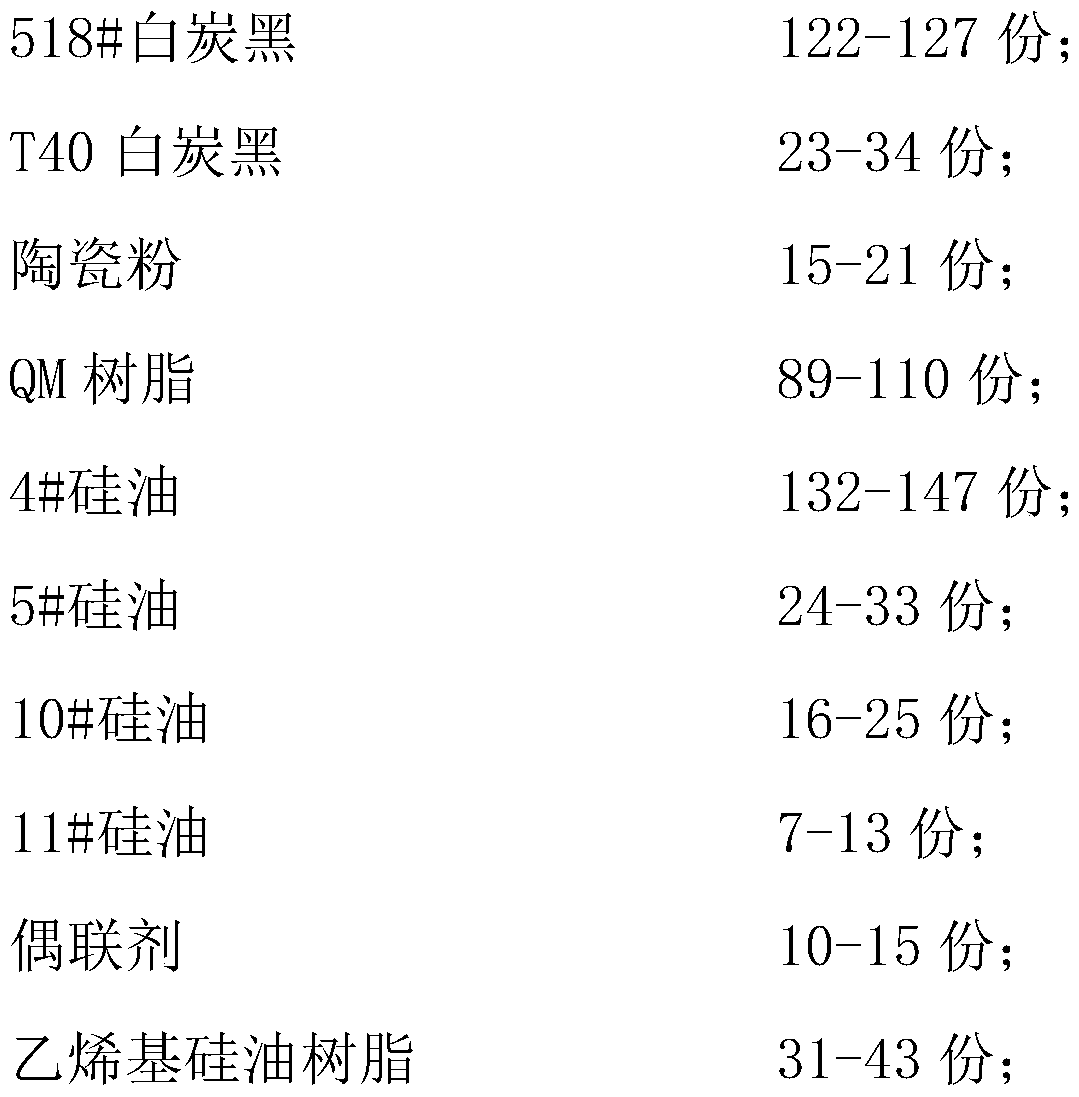

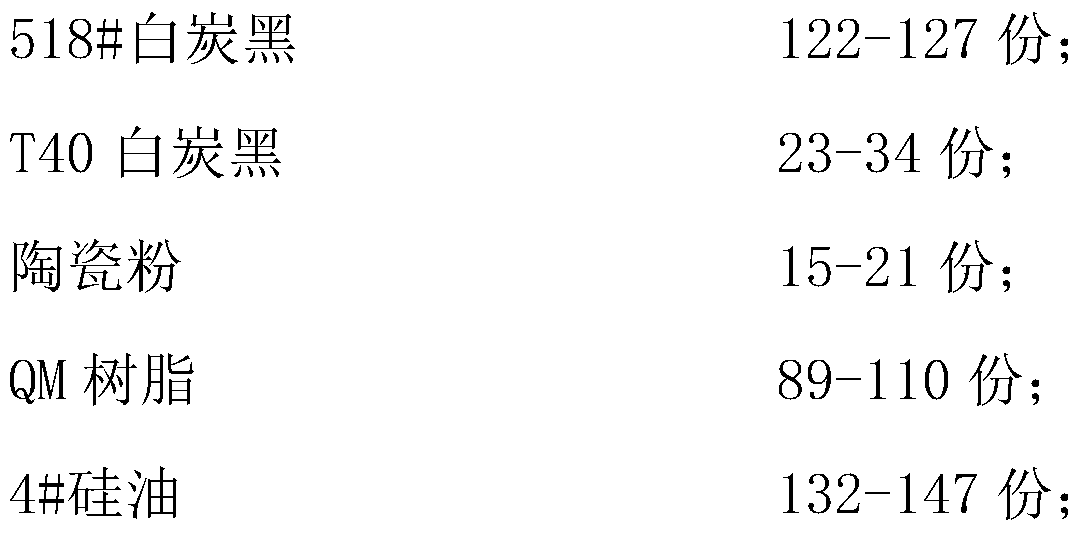

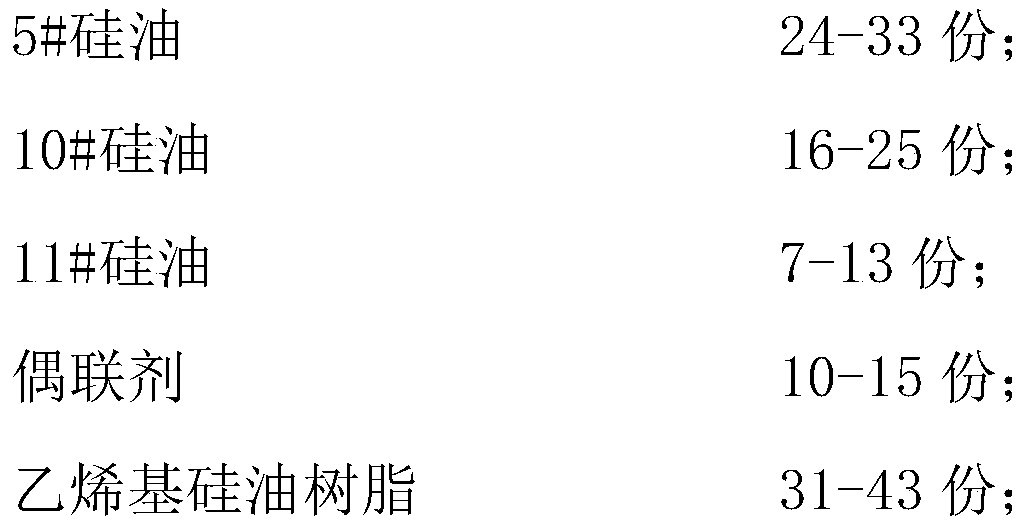

[0019] The glue for PET insulating bushing that the embodiment of the present invention provides, its component is: 518# white carbon black 122kg; T40 white carbon black 34kg; Ceramic powder 15kg; QM resin 89kg; 4# silicone oil 132kg; 5# silicone oil 33kg; #Silicone oil 25kg; 11# silicone oil 13kg; coupling agent 15kg; vinyl silicone oil resin 31kg.

Embodiment 2

[0021] The glue for PET insulating bushing that the embodiment of the present invention provides, its component is: 518# white carbon black 127kg; T40 white carbon black 23kg; Ceramic powder 21kg; QM resin 110kg; 4# silicone oil 147kg; 5# silicone oil 24kg; #Silicone oil 16kg; 11# silicone oil 7kg; coupling agent 10kg; vinyl silicone oil resin 43kg.

Embodiment 3

[0023] The glue for PET insulating bushing that the embodiment of the present invention provides, its component is: 518# white carbon black 126kg; T40 white carbon black 27kg; Ceramic powder 19kg; QM resin 103kg; 4# silicone oil 139kg; 5# silicone oil 27kg; #Silicone oil 19kg; 11# silicone oil 11kg; coupling agent 12kg; vinyl silicone oil resin 36kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com