Annealing equipment used in copper cladding aluminum or aluminum cladding copper magnesium thread production

A technology of copper-clad aluminum-magnesium and annealing equipment, applied in heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve problems such as broken wires, achieve the effects of increased tensile strength and elongation, simplified settings, and bright surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

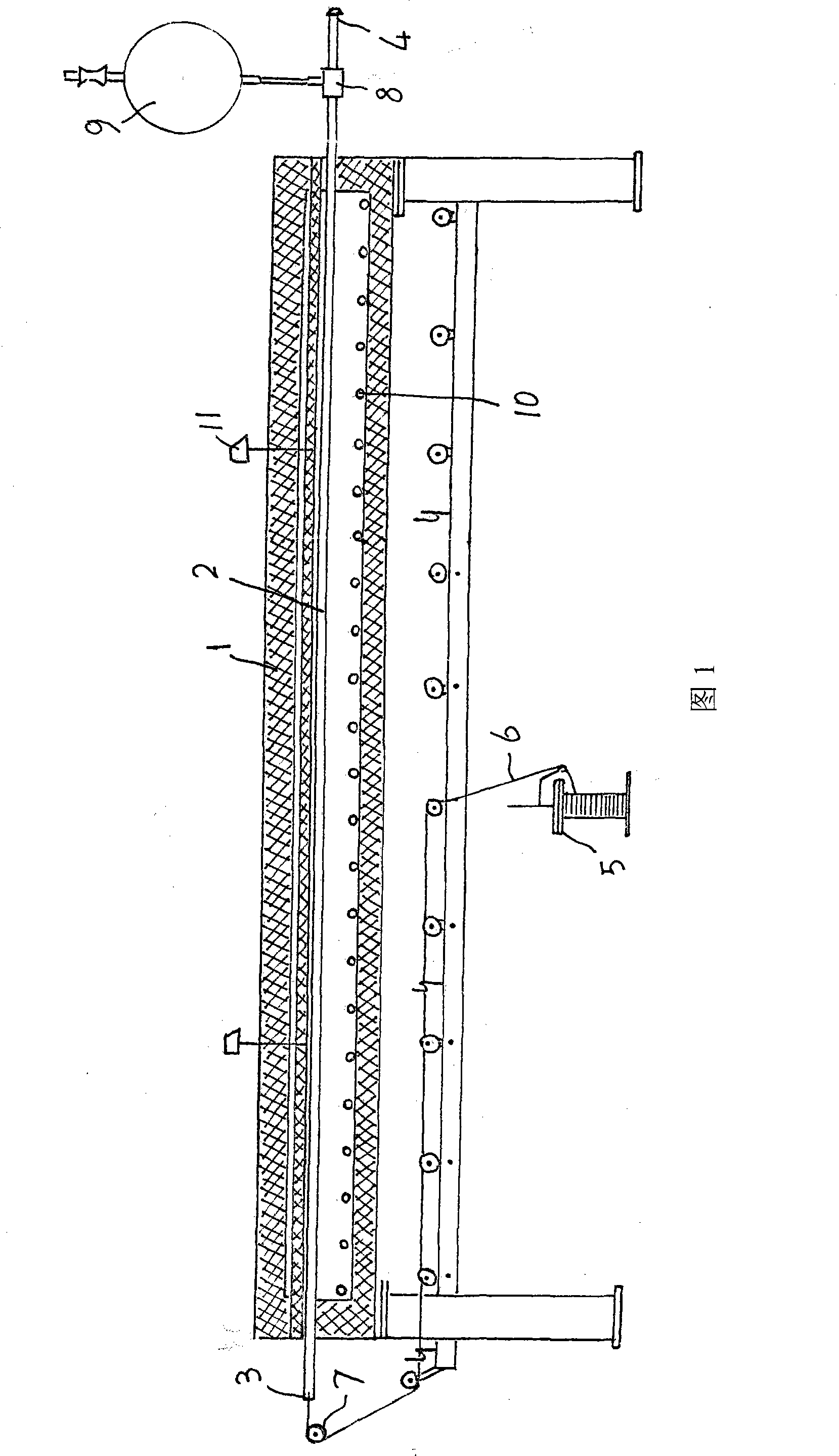

[0021] The present invention improves the existing production process of copper-clad aluminum or copper-clad aluminum-magnesium wire. The whole process line is the same as that of the prior art, including starting from the acceptance of raw materials, successively passing through intermediate drawing and rough drawing, and then using the present invention for annealing. process, annealing the raw silk under the protection of hydrogen in an anti-oxidation atmosphere.

[0022] Set the annealing temperature in the range of 350-450°C, which can be specifically selected as 350°C, 360°C, 370°C, 380°C, 400°C, 420°C or 440°C, etc.; the hydrogen pressure is 0.3-1.0MPa, which can be specifically selected as 0.3 MPa, 0.4MPa, 0.5MPa, 0.6MPa, 0.7MPa, 0.8MPa, 0.9MPa or 1.0MPa; the annealing time is 1.5 seconds to 3.5 seconds, which can be selected as 1.5 seconds, 1.6 seconds, 1.8 seconds, 2 seconds, 2.2 seconds , 2.5 seconds, 2.8 seconds, 3.0 seconds, 3.2 seconds or 3.5 seconds etc.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com