Weft insertion device of latch needle warp knitting machine

A weft insertion device and warp knitting machine technology, which is applied to flat warp knitting machines, warp knitting, knitting, etc., can solve the problems of single type of weft yarn and uneven tension of weft yarn in interlining, so as to improve profit margin and cloth surface Smooth and beautiful, enhance the effect of design flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

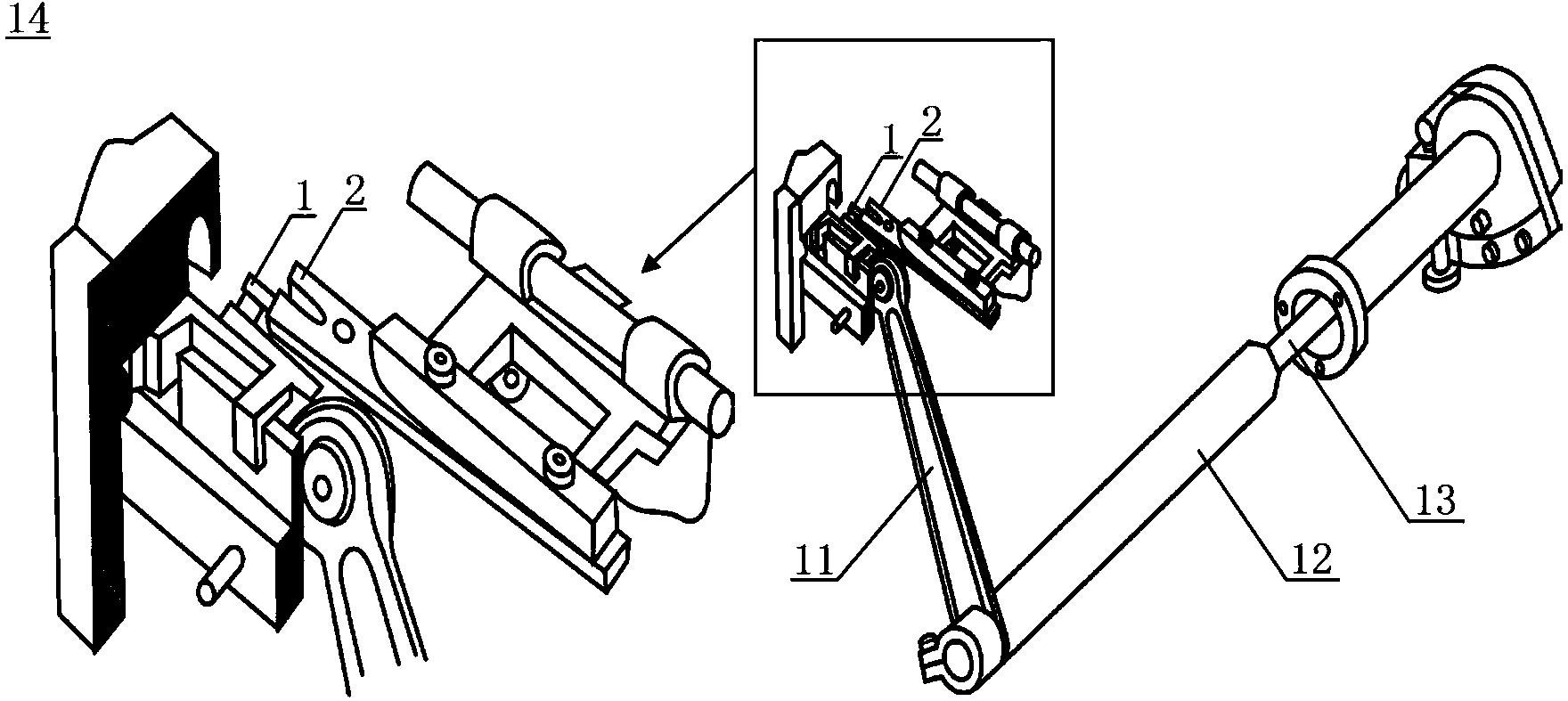

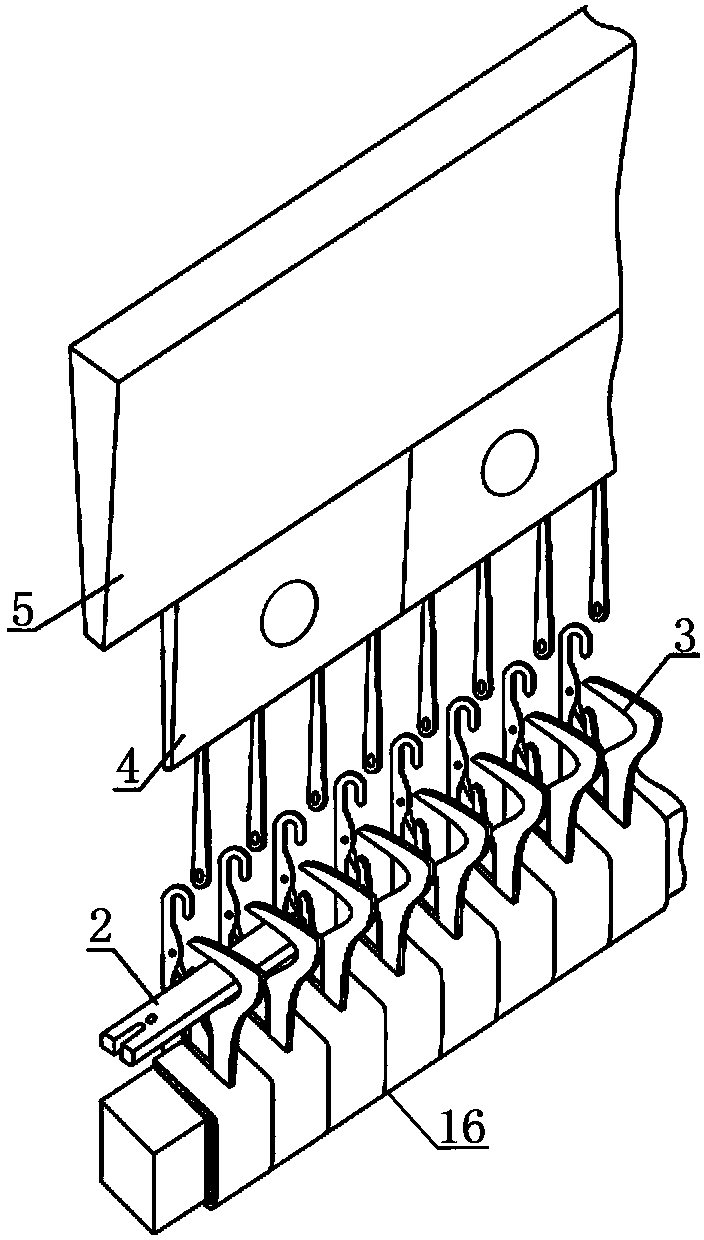

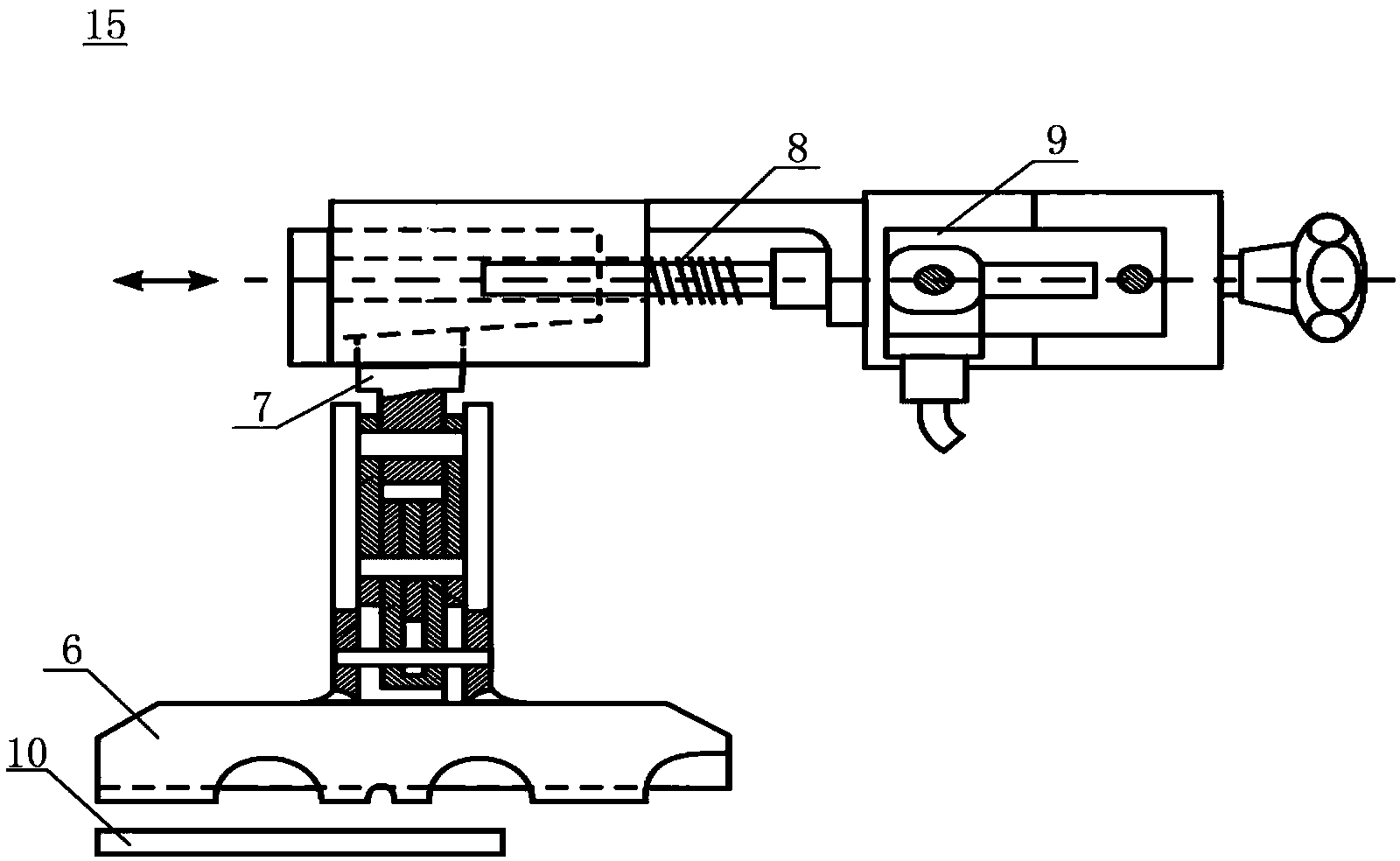

[0019] as attached figure 1 to attach Figure 4 As shown, according to an embodiment of the present invention, the weft insertion device includes a shuttle knocking block 1, a shuttle 2, a shuttle guide piece 3, a yarn guide needle block 4, a yarn guide comb 5, a shuttle picking mechanism 14 and a shuttle making mechanism 15, The shuttle block 1 is placed at the rear portion of the shuttle 2 and within the range that can effectively hit the shuttle 2, the shuttle 2 can pass smoothly along the guide shuttle sheet 3, and the yarn guide needle block 4 is installed under the yarn guide comb 5, and the throwing Shuttle mechanism 14 is installed on one side of warp knitting machine head, and shuttle making mechanism 15 is installed on one side of warp knitting machine tail; Including the shuttle foot 6, the lifting block 7, the adjusting screw 8, the stepping motor 9 and the lower shuttle plate 10, the stepping motor 9 is connected with the adjusting screw 8, the adjusting screw 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com