Electrical cabinet with high temperature early warning system

An early warning system and electrical cabinet technology, applied in the field of electrical cabinets, can solve problems such as damage to electrical components, lack of reminders for on-duty personnel, and losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

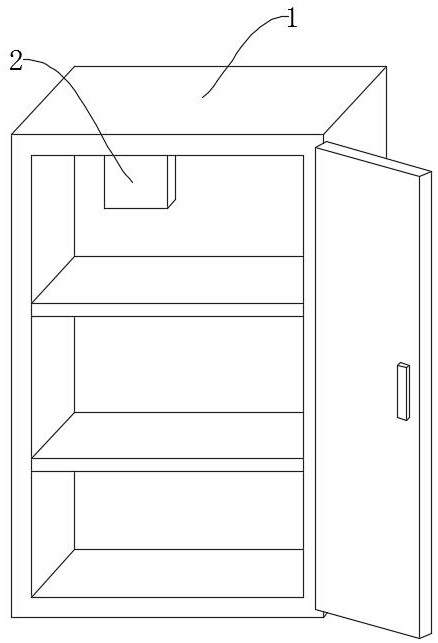

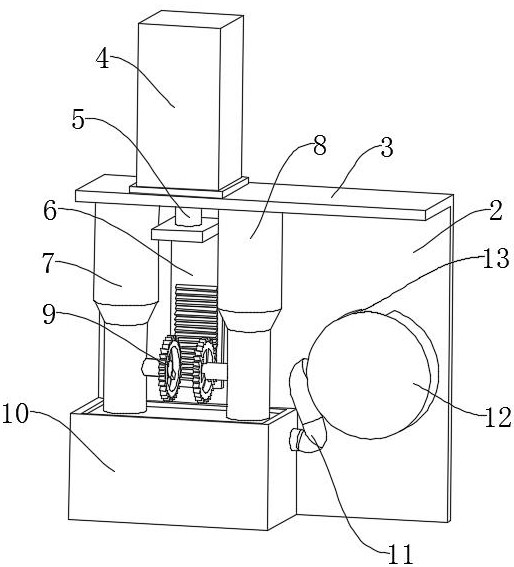

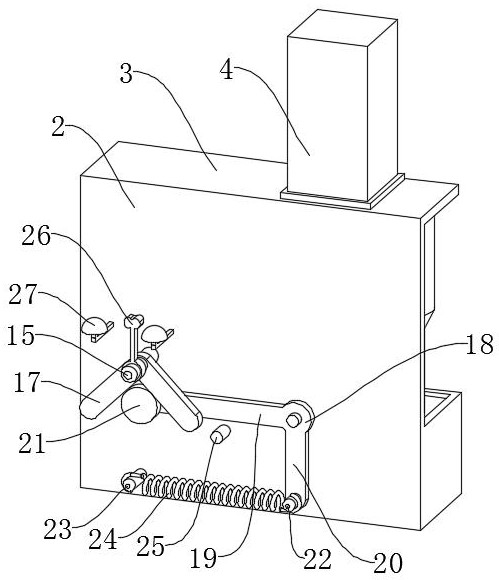

[0034] see Figure 1-5 , an electrical cabinet with a high temperature early warning system, comprising a cabinet body 1, a side panel 2 is fixedly connected to the inner side wall of the cabinet body 1, a top panel 3 is fixedly connected to the upper end surface of the side panel 2, and a casing is fixedly connected to the upper surface of the top panel 3 4. There is a cavity inside the shell 4, and there is metal mercury in the cavity. The piston rod 5 is slidably connected to the inner wall of the cavity. The lower end of the piston rod 5 extends to the bottom of the top plate 3 and is fixedly connected to the rack 6. 2 One side is fixedly connected with the first storage chamber 7 and the second storage chamber 8, the first storage chamber 7 is provided with sodium bicarbonate solution, the second storage chamber 8 is provided with aluminum sulfate solution, and the side plate 2 is fixedly connected with Reactor 10, the lower end of the first storage chamber 7 and the seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com