Automatic fish cream production and treatment device

A processing device and fish paste technology, applied in chemical/physical processes, mixers with rotating stirring devices, transportation and packaging, etc., can solve the problems of poor automation and the effect of investing a large amount of labor, and achieve the goal of improving automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

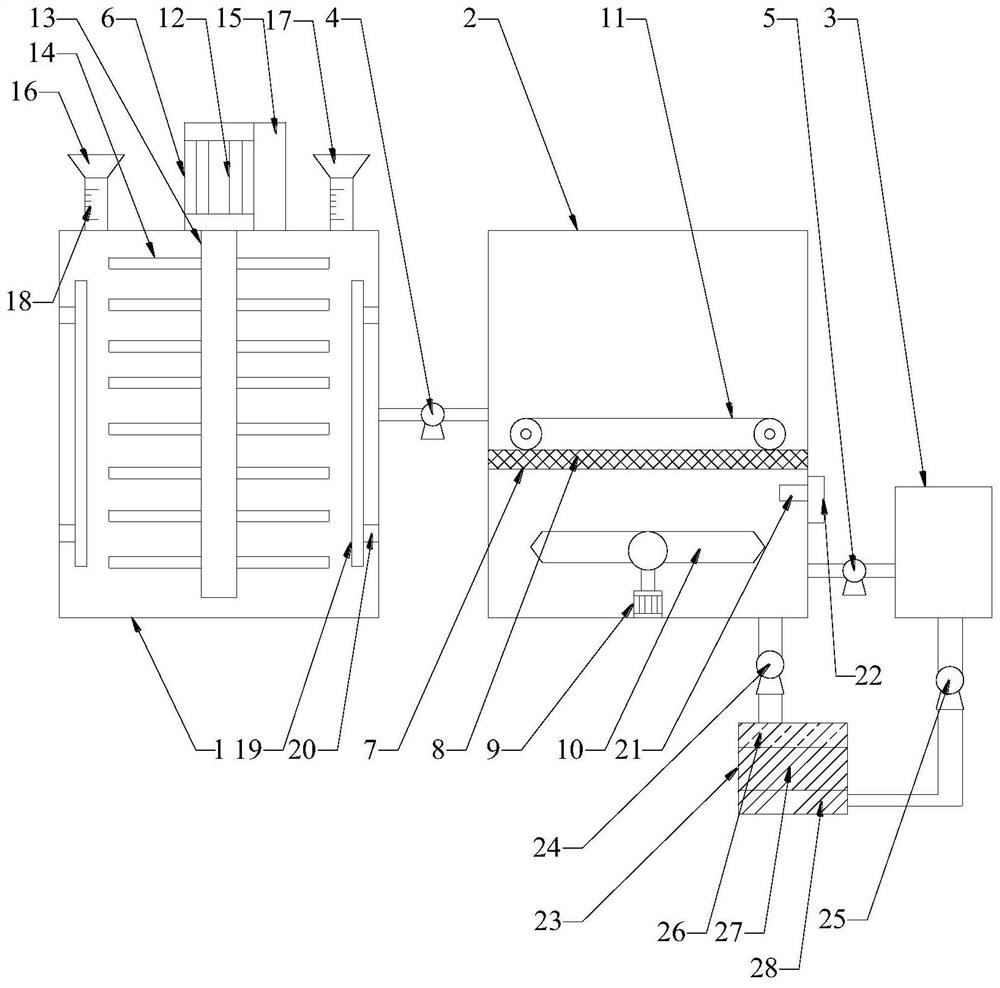

[0054] Please refer to figure 1 Shown, embodiment one of the present invention is:

[0055] An automatic fish paste production and processing device, comprising a first stirring mechanism 1, a first cleaning mechanism 2 and a first water tank 3, the first stirring mechanism 1 is connected with the first cleaning mechanism 2 through a first pump 4, The first water tank 3 is connected to the first cleaning mechanism 2 through the first water pump 5, the first stirring mechanism 1 is provided with a first stirring assembly 6, and the first cleaning mechanism 2 is provided with a first passage Water net 7, the two ends of described first water net 7 are connected with the inner side wall of first cleaning mechanism 2, and described first water net 7 is provided with a plurality of water holes 8, and described first cleaning The bottom of the mechanism 2 is provided with a first motor 9 , the output shaft of the first motor 9 is provided with a first stirring blade 10 , and the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com