Steel bar cage forming positioning device and steel bar cage forming equipment

A positioning device and steel bar technology, applied in the field of construction machinery, can solve problems such as unsatisfactory, and achieve the effect of stepless adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

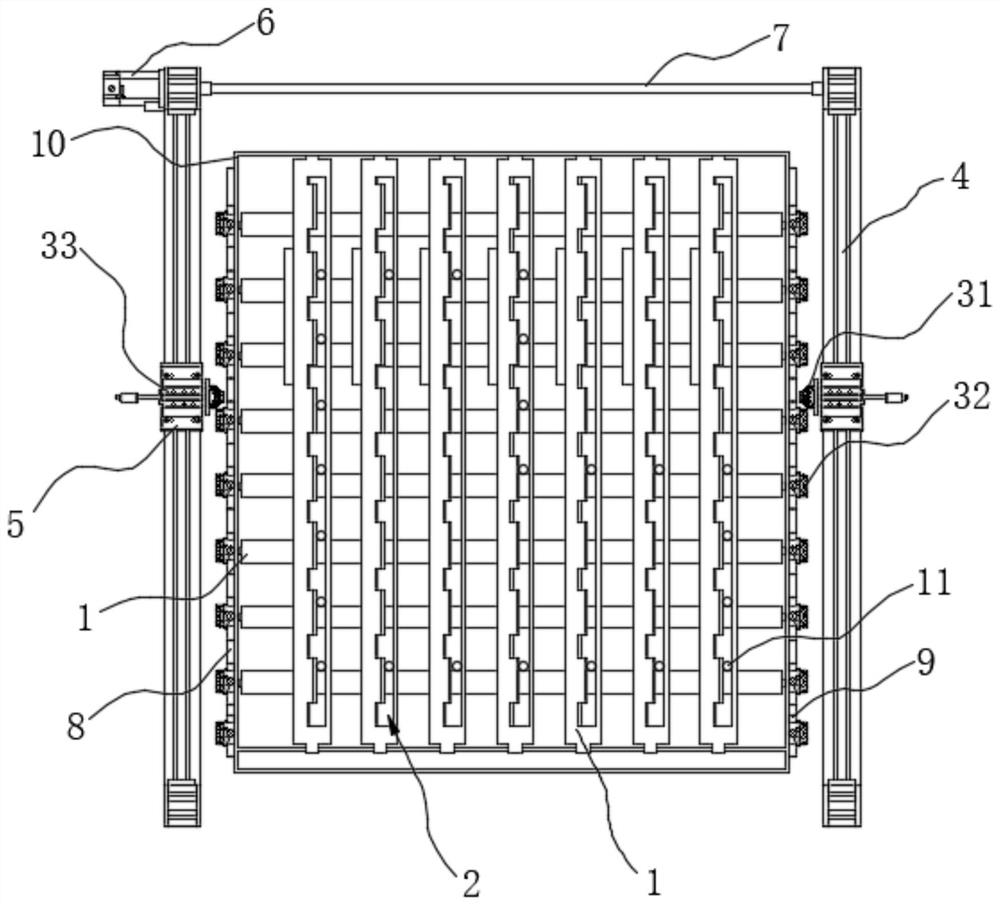

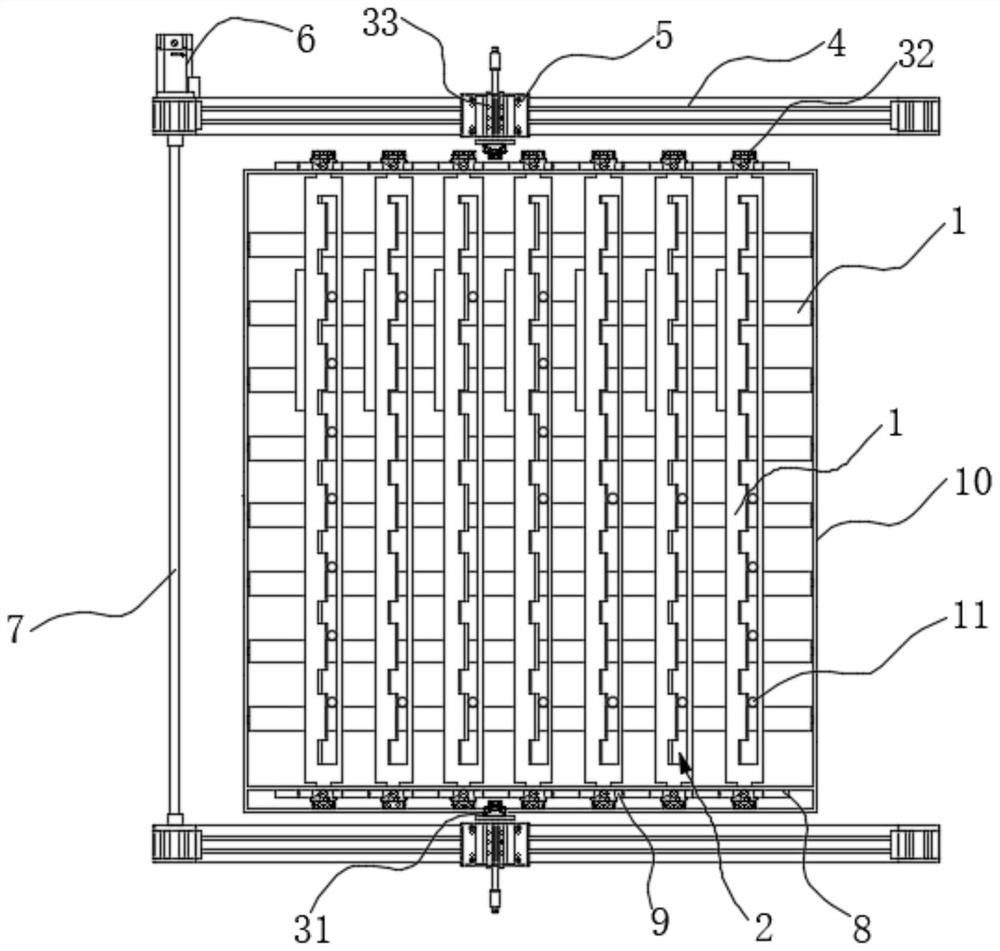

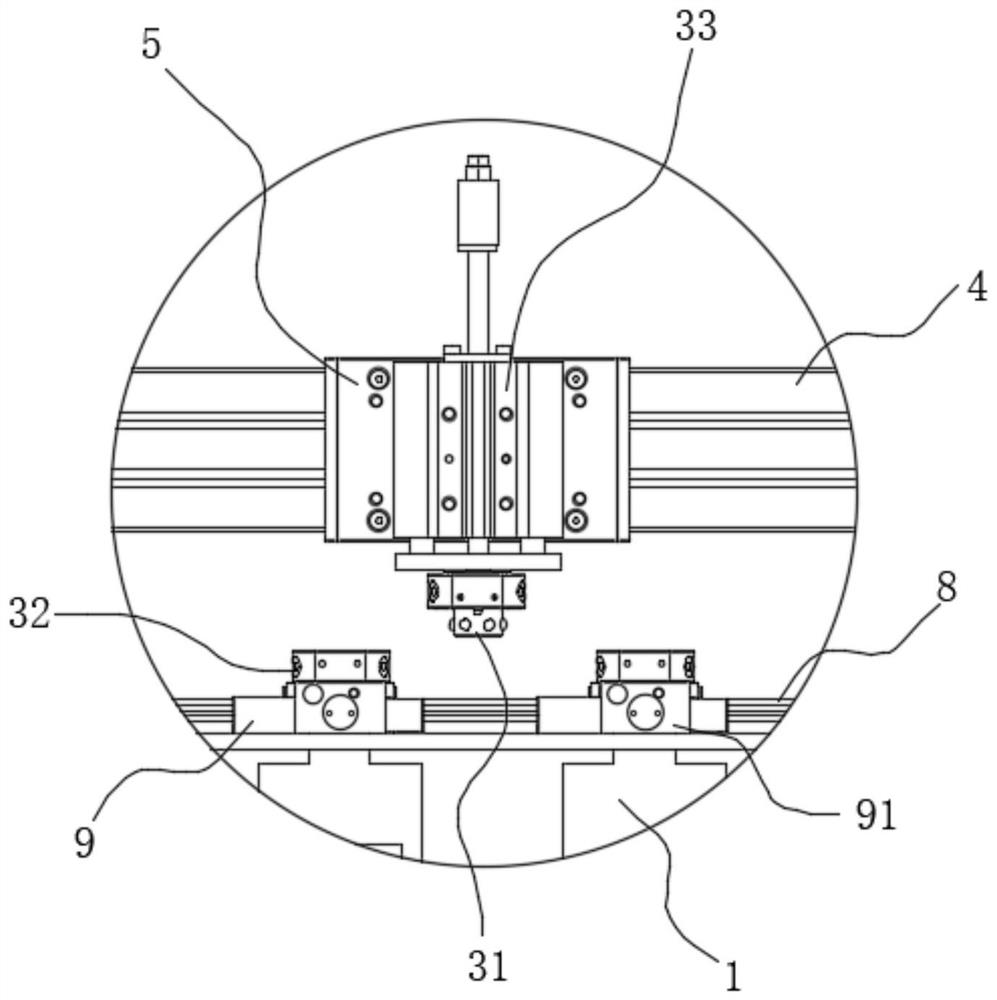

[0049] Such as Figure 1 to Figure 4 As shown, this embodiment provides a reinforcing bar cage positioning device, which is used to provide positioning for the reinforcing bars 11 when the reinforcing bars 11 are combined and connected into a cage shape. The reinforcement cage positioning device includes a limit piece 1 and a quick change device at the end, wherein there are multiple limit pieces 1, and the multiple limit pieces 1 are arranged side by side along the extension direction perpendicular to the limit piece 1, and can be aligned along the arrangement direction. To move, the ends on the same side of a plurality of limiters 1 correspond to the same end quick change assembly, each end quick change assembly includes a detachably connected first joint 31 and a plurality of second joints 32, each limit A second joint 32 is mounted on each end of the piece 1, and the first joint 31 can be connected to any one of the plurality of second joints 32 to drive the position-limit...

Embodiment 2

[0065] This embodiment provides a reinforcement cage forming device, including the reinforcement cage positioning device provided in Embodiment 1, which is used to combine and fix the reinforcement bars 11 into reinforcement cages of various shapes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com