Multi-adaptive eccentric adjusting mechanism

An eccentric adjustment mechanism and adaptive technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of inability to install, and the hole positions on the two devices cannot correspond to each other, and achieve simple structure, low manufacturing cost, and improved adaptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

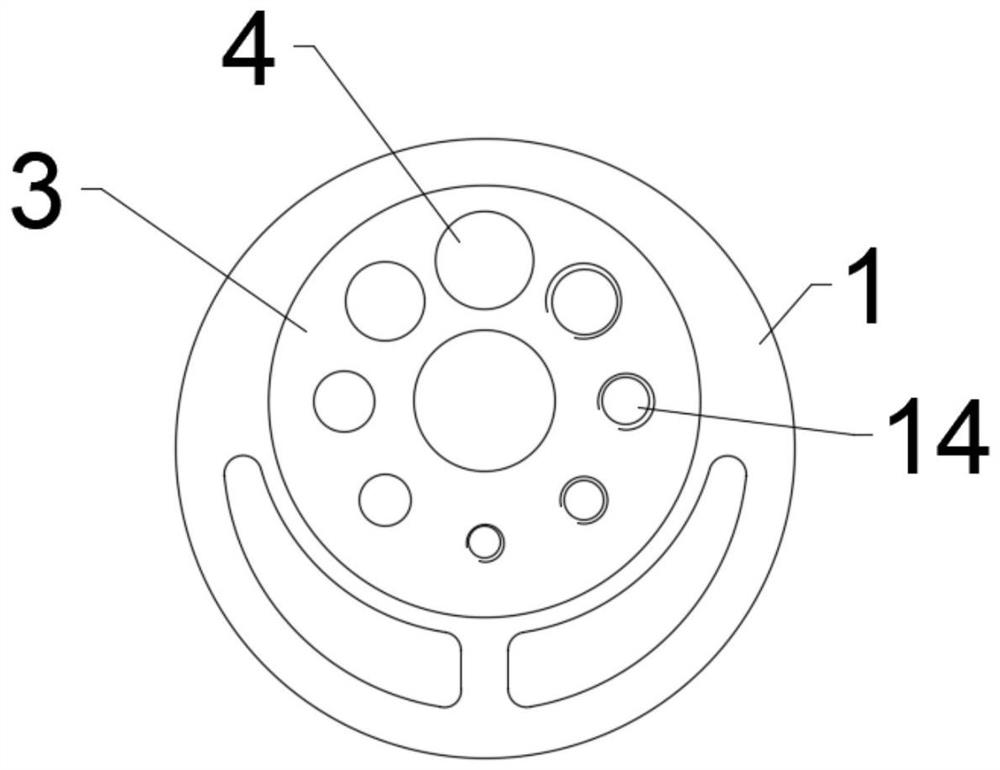

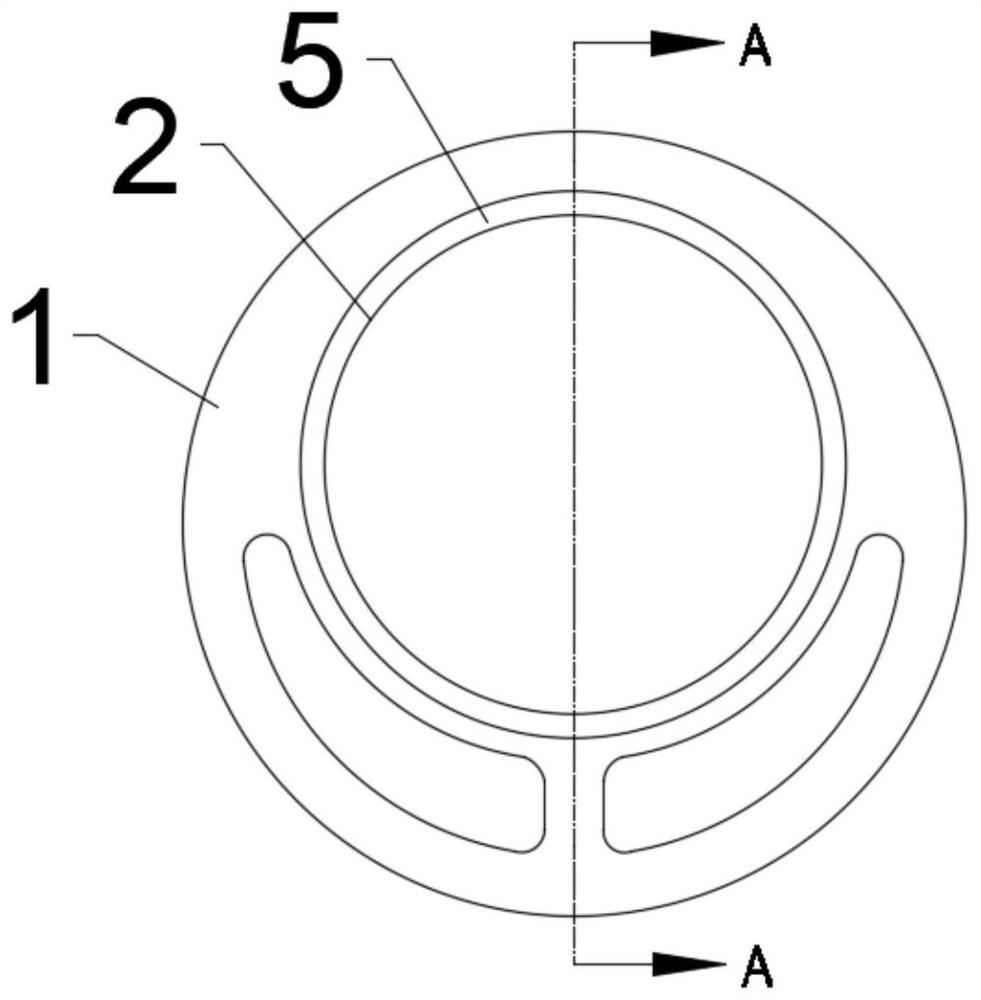

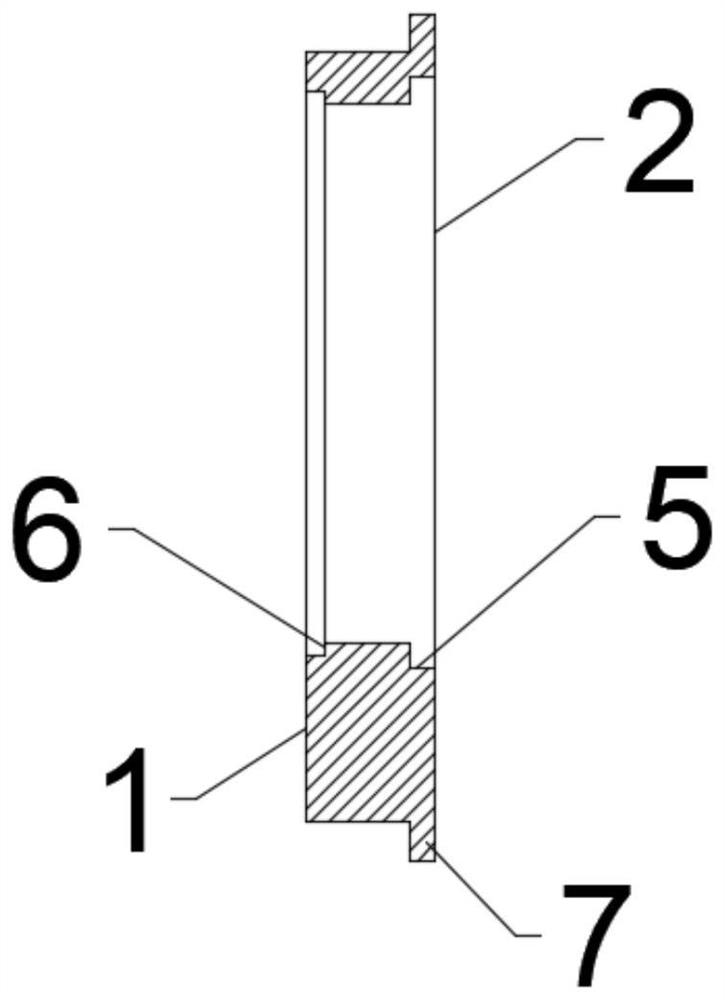

[0040] Such as Figure 1-Figure 8 As shown, this embodiment provides a multi-adaptive eccentric adjustment mechanism, including: an eccentric ring 1 and a connecting disc 3 .

[0041] An eccentric circular hole 2 is arranged on the eccentric ring 1 . The connecting disc 3 is rotatably connected in the eccentric circular hole 2 . The connecting disc 3 is provided with a plurality of connecting holes for connecting with the fixing member B12 .

[0042] Wherein, the outer ring wall of the eccentric ring 1 is a cylindrical surface, which is convenient for contact and fit with the fixing part A11. The eccentric ring 1 forms a ring through the eccentric circular hole 2 , and the eccentric circular hole 2 passes through the eccentric circular ring 1 along the axis direction of the eccentric circular ring 1 . Wherein, the connecting disc 3 is used to connect with the fixing part B12, wherein the fixing part B12 is provided with a corresponding hole, and the connecting hole on the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com