Multi-directional mechanical arm for 3D printing

A 3D printing and robotic arm technology, applied in manipulators, manufacturing tools, etc., can solve problems such as poor quality, nozzle larger than part error, nozzle vibration, etc., to achieve good suspension flexibility, prevent nozzle shaking, and increase accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

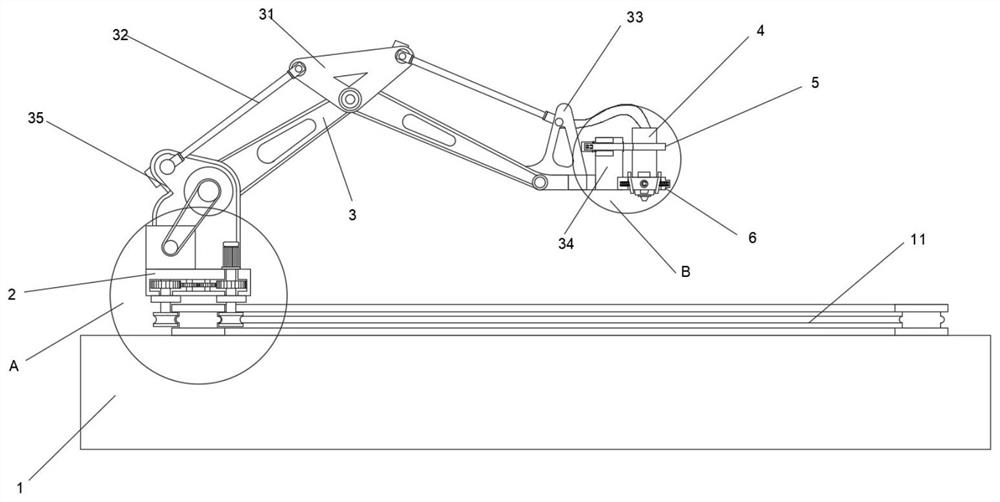

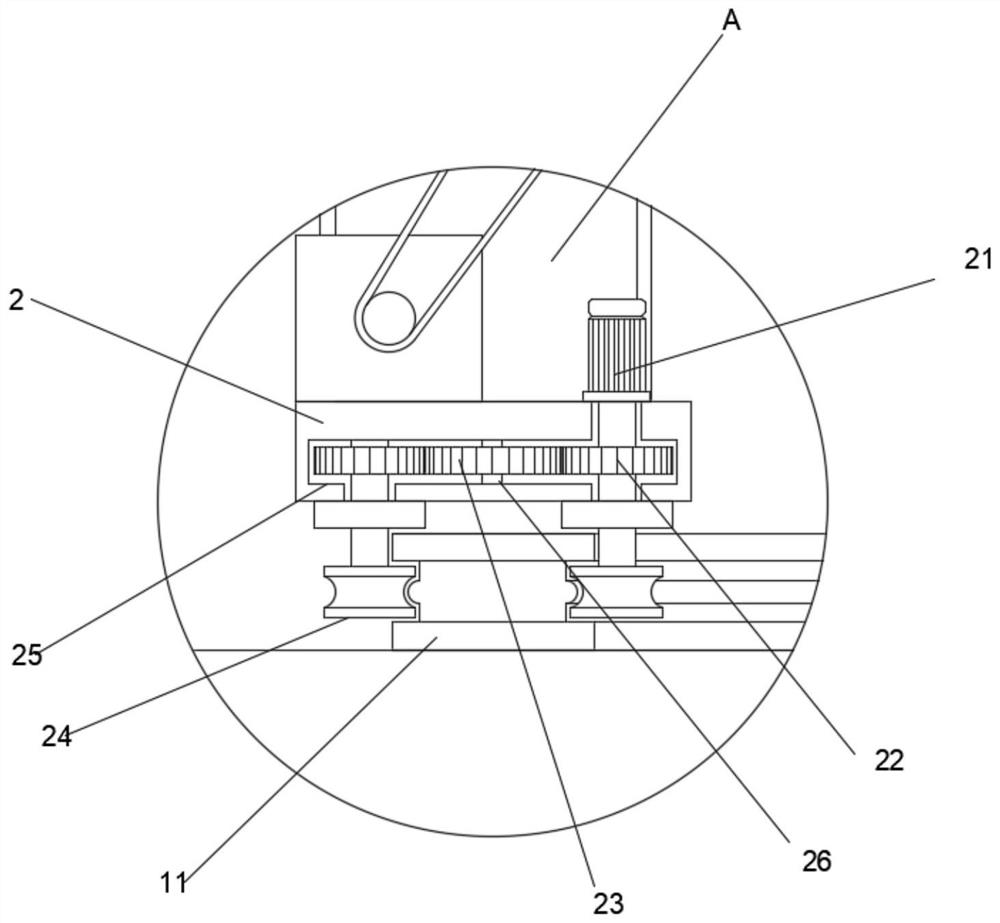

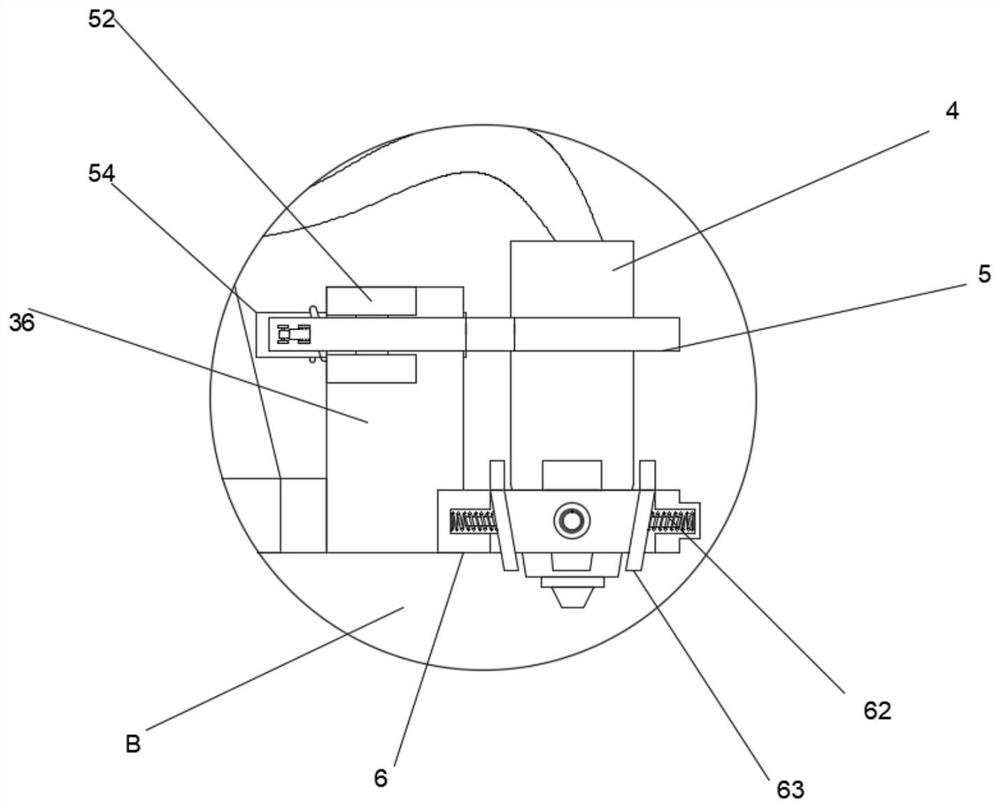

[0024] See Figure 1 to 6 The present invention provides a technical solution: one 3D printing multi-directional robot arm, including the base 1, the swing arm 3, the nozzle 4, and the casing 5, the upper surface of the base 1 is provided with curved rail 11, curved smooth The upper end of the left side of the rail 11 slides a moving seat 2, and the lower surface of the moving seat 2 is provided with two sets of roller 24, and the two sets of roller 24 are engaged on the left and right sides of the curved rail 11, and the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com