Semi-automatic production line for preparing assembly type light wallboard

A light-weight wallboard and semi-automatic technology, applied in the direction of supply devices, manufacturing tools, auxiliary molding equipment, etc., can solve the problems of undisclosed and other issues, and achieve the effect of easy control of both feeding and discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

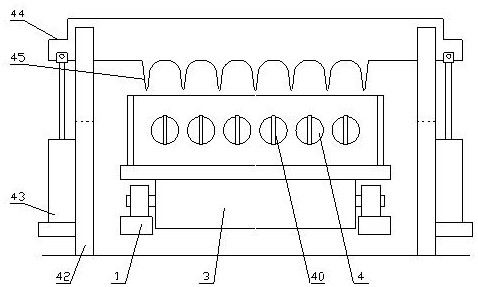

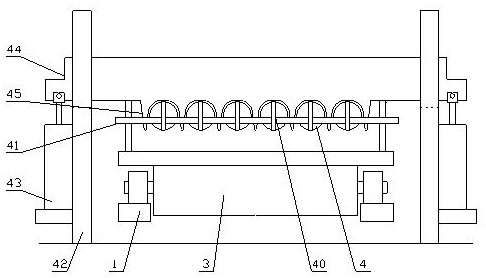

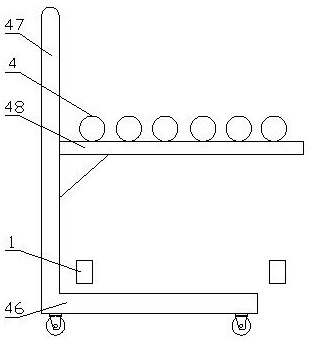

[0043] see Figure 1-12 , the embodiment of the present invention provides a semi-automatic production line for preparing assembled lightweight wallboards, including a preparation slide rail 1 (consisting of two rails, specifically 40-80m in length), a material mixing device (mixing various raw materials and sending bubble), tube pulling device (for pulling out the mold tube 4), forming device (for molding), curing kiln 2 (for curing) on the side of the preparation slide rail 1 and parallel to it (for curing) and sliding on the preparation slide rail 1 Multiple molds 3 (for conveying and forming, able to slide on each track) etc. Among them, the preparation slide rail 1 (curing kiln 2) is set along the front and rear directions, the molding device and the mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com