Anti-skid type sealing, shaping and slitting device with detachable tool bit and operation method thereof

A non-slip, cutter head technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of affecting the qualification rate and production efficiency, increasing the cost of use, falling pipes, etc. The effect of saving costs and improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

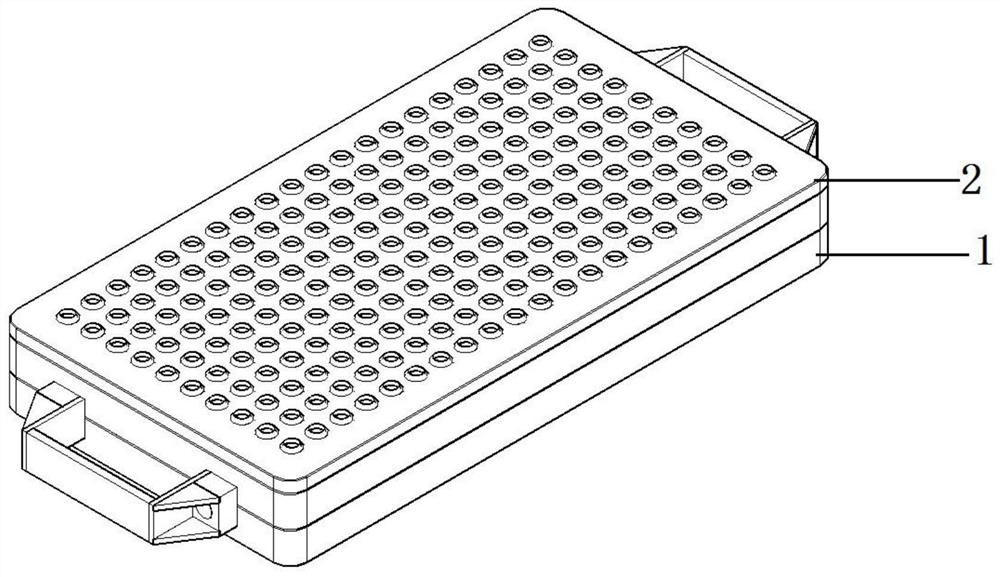

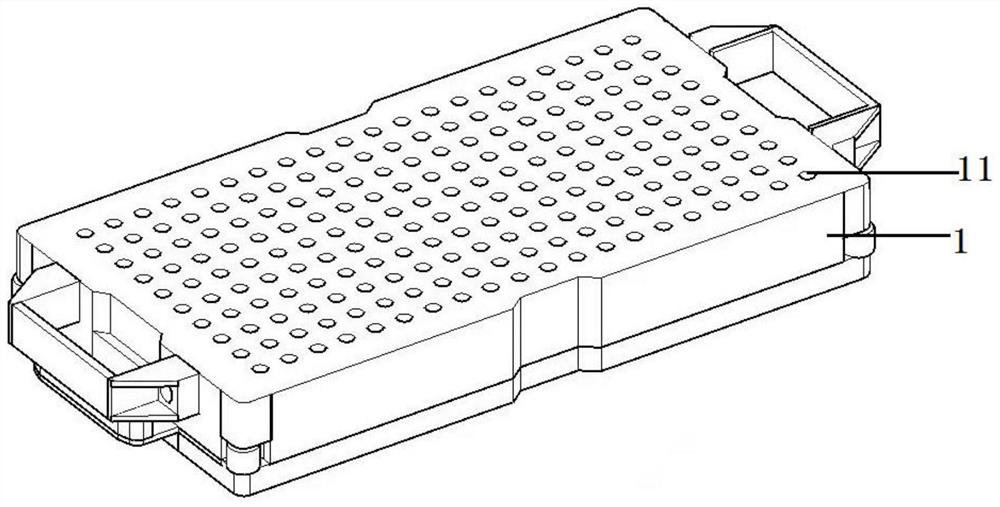

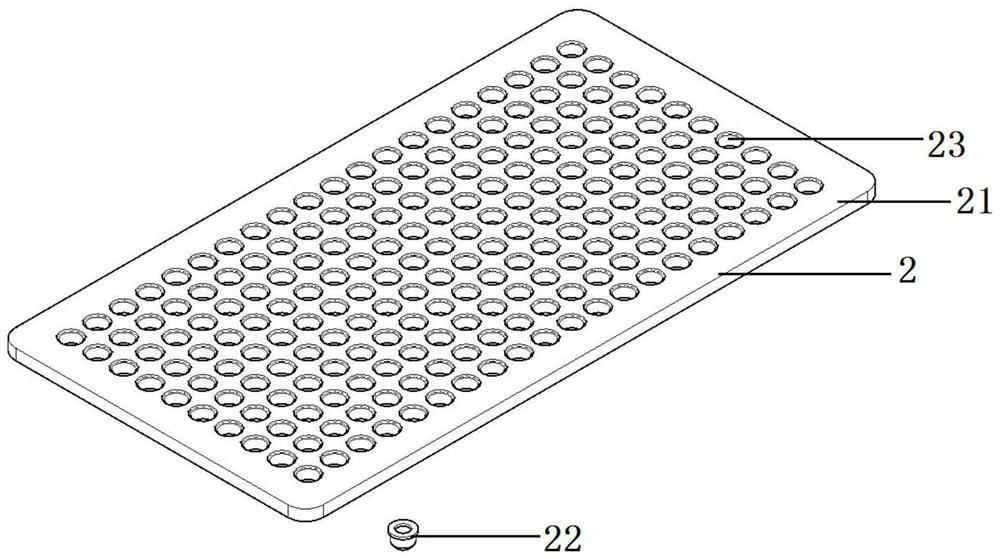

[0056] Such as figure 1 As shown, this embodiment uses a non-slip sealing shaping and cutting device with a detachable cutter head. After pasting the sealing paper on one end of the tube body of the aerosol generating product, the excess sealing paper is cut off to make the aerosol generating product There is a sealing film at one end of the product tube body; the non-slip sealing shaping and cutting device with a detachable cutter head includes: a receiving part 1, a cutter head part 2, and an anti-skid part 3; at least one The accommodating groove 11 that runs through the accommodating part 1 longitudinally; the accommodating groove 11 has the anti-slip part 3 at least in a partial area; the cutter head part 2 includes a main board 21 and a cutter head 22, and the main board 21 has a knife A head installation hole 23 , the cutter head 22 is detachably connected to the cutter head installation hole 23 ; one end of the receiving part 1 is connected with the cutter head part 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com