Clothes lifting device for washing machine and roller washing machine

A technology for washing machines and clothing, applied in the field of clothing lifting devices for washing machines and drum washing machines, can solve the problems of affecting the normal operation of springs, being difficult to remove, and the centrifugal valve being closed in place, etc., so as to improve user health and user experience, and reduce washing water. The effect of reducing the amount of dirt and preventing the adhesion of dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

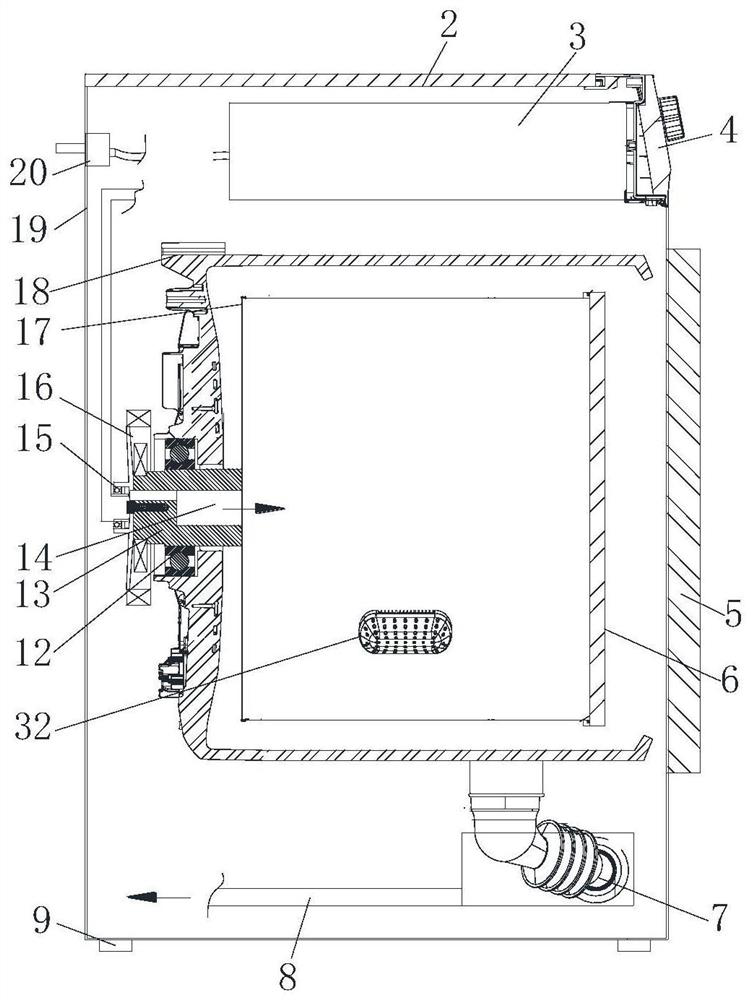

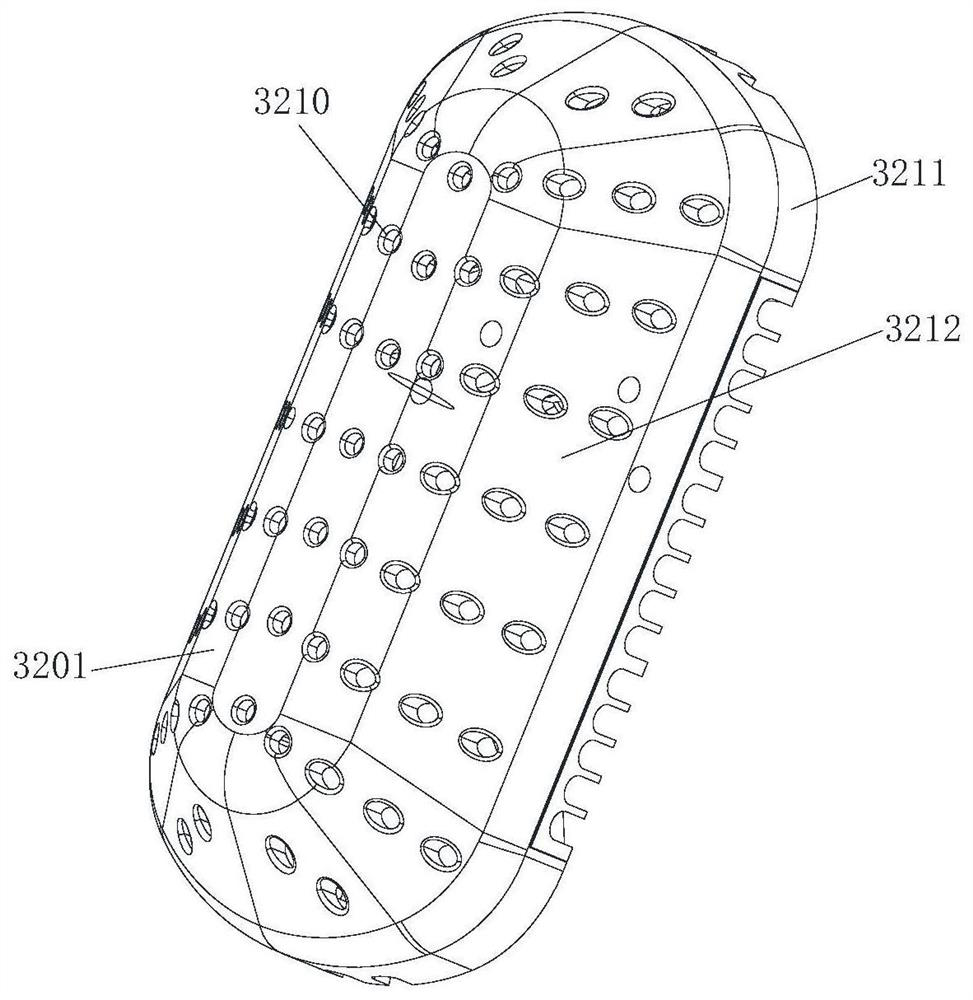

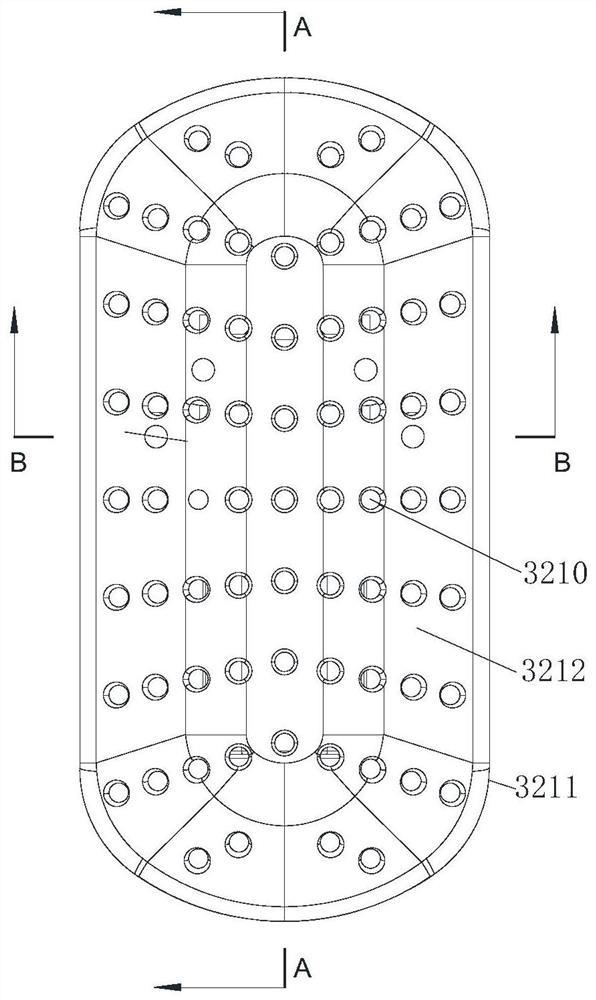

[0051] like Figure 1-9 As shown, a laundry lifting device for a washing machine and a drum washing machine according to the present embodiment.

[0052] A laundry lifting device 32 for a washing machine, comprising:

[0053] The body has an accommodation chamber inside;

[0054] The water inlet is arranged on the body and communicates with the containing chamber;

[0055] and a centrifugal drainage assembly, which is arranged in the accommodating chamber. The initial state of the centrifugal drainage assembly is a closed state, and it can be opened to drain water under the action of centrifugal force.

[0056] The clothing lifting device of this embodiment can be installed on the inner wall of the inner cylinder of the drum washing machine. During the washing process, the clothes are lifted to a certain height and dropped down along with the rotation of the inner cylinder. In this embodiment, a centrifugal drainage assembly is integrated in the clothes lifting device. The ...

Embodiment 2

[0071] like figure 1 , Figure 10 , 11 As shown in and 12, since the initial state of the centrifugal drainage assembly of this embodiment is a closed state, the centrifugal drainage assembly includes a compression spring to provide a pressing force to maintain the closed state, and the water in which the centrifugal drainage assembly is located inevitably contains clothing lint , if the swarf hangs on the elastic member, it is not easy to fall off, even if the drainage water flow, centrifugal water flow and centrifugal force may not be able to separate the swarf from the elastic member; furthermore, the swarf hanging on the elastic member has a certain length , Part of the unhanging parts reach the drain hole and / or the sealing plunger of the inner cylinder under the action of drainage water flow, centrifugal water flow and centrifugal force, resulting in the problem of seal failure.

[0072] Since the centrifugal drainage assembly is an important drainage component of the ...

Embodiment 3

[0096] like figure 1 As shown, this embodiment also provides a drum washing machine with the laundry lifting device for washing machines, including:

[0097] Inner barrel 17;

[0098] The inner cylinder door 6 is installed on the mouth of the inner cylinder 17 which can be opened / closed;

[0099] When the inner cylinder door 6 is closed, it forms an independent washing chamber together with the inner cylinder 17, and independently holds washing water when washing clothes;

[0100] A water outlet is provided on the side wall of the inner cylinder 17, the lifting device 32 is installed on the water outlet on the inner wall of the inner cylinder 17, and the centrifugal drainage assembly blocks and closes the water outlet.

[0101] The drum washing machine of this embodiment installs the inner cylinder door 6 on the mouth of the inner cylinder 17, and the inner cylinder 17 adopts a non-porous cylinder design, and the two together form an independent washing chamber. Filling the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com