Method for preventing muck from being accumulated on upper surface of foundation pit supporting beam

A technology for supporting beams and muck, which is applied in excavation, infrastructure engineering, and processing of building materials, etc. It can solve problems affecting the stability of supporting beams, injuring construction personnel, and threatening the safety of operating personnel, so as to save labor and save money. The effect of benefits and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention can be explained in more detail by the following examples, disclosing all changes and modifications within the scope of the invention, the invention is not limited to the following embodiments;

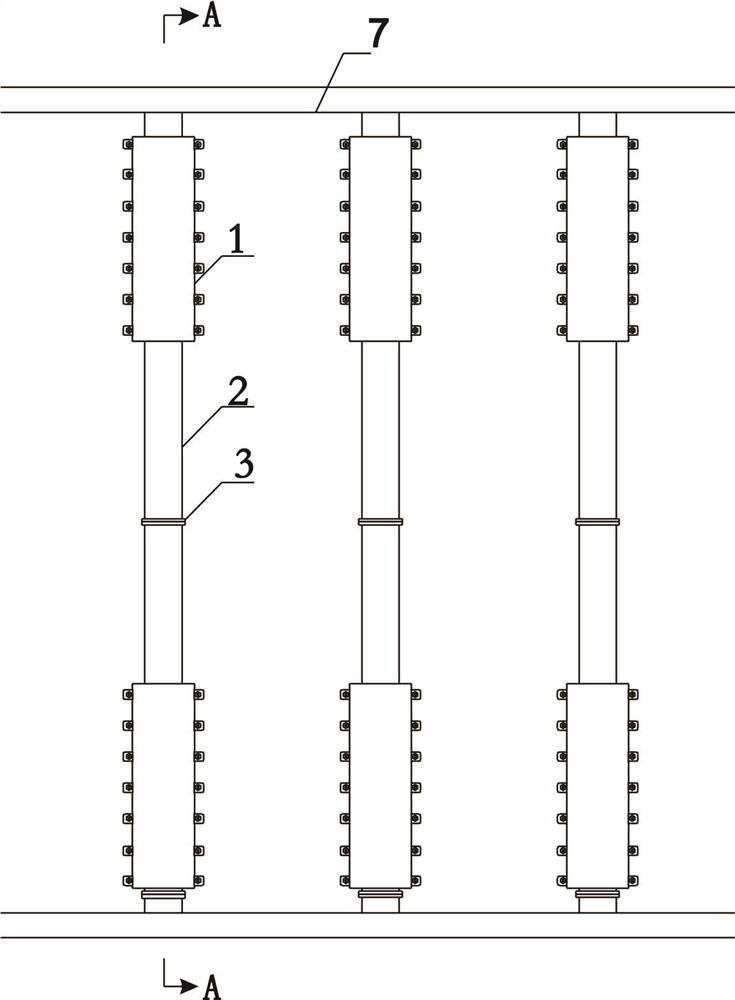

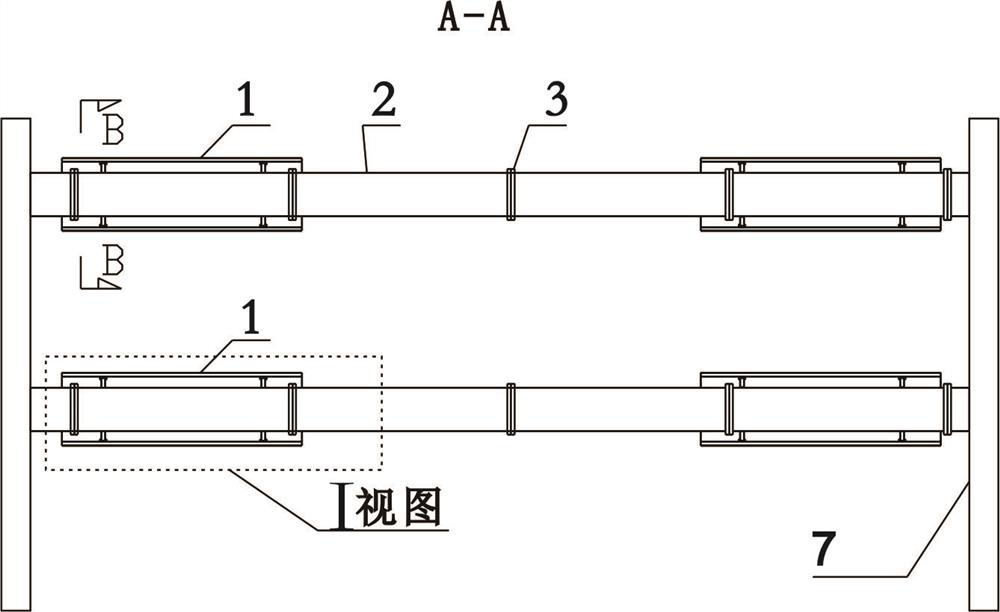

[0024] A method of preventing a surface area of the surface area of the foundation pit support beam in conjunction with the drawings,

[0025] 1) Prefabricated slag soil

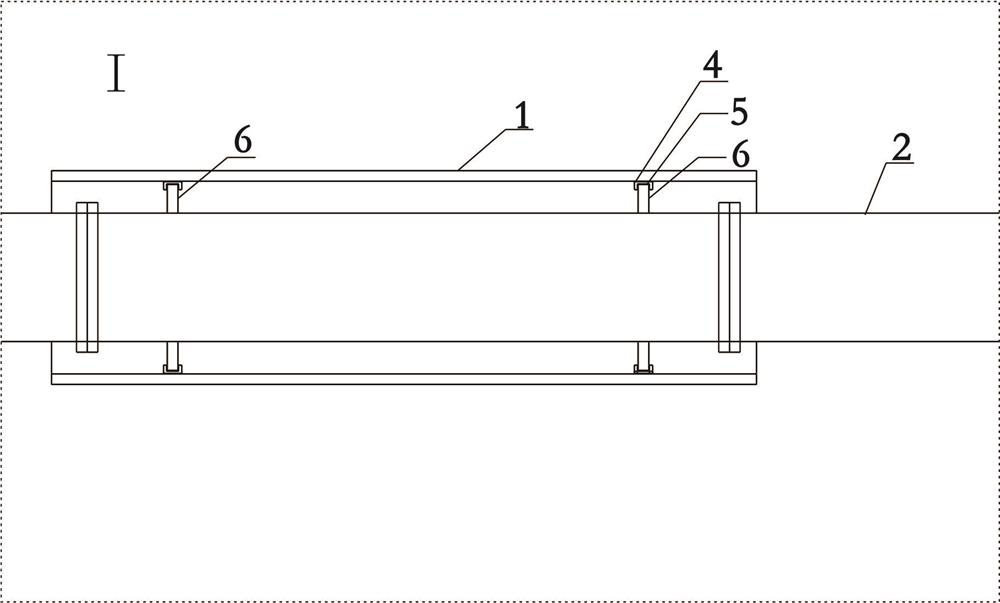

[0026] The slag miles include a hug 6, a slide 4, and a sleeve 1, and the hoop 6 is spliced from the upper hug and the lower hug, and the inner diameter of the ring-shaped hoop 6 is spliced from the radius of the support beam 2. Size determination; slide 4 is formed by the upper slide and sliding to splicing, and the size of the ring slide 4 in which the spliced ring slide 4 is determined by the outer diameter dimension of the hoop 6, and a groove 5 is provided inside the slide 4;

[0027] The sleeve 1 is coupled by the upper sleeve and the lower sleeve, and the upper sleeve and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com