Using method of anti-impact collaborative yielding annular support for deep well roadway

A technology of ring support and deep well roadway, which is applied in the direction of pillar/support, tunnel, shaft lining, etc., and can solve problems such as support and difficult deep well roadway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples.

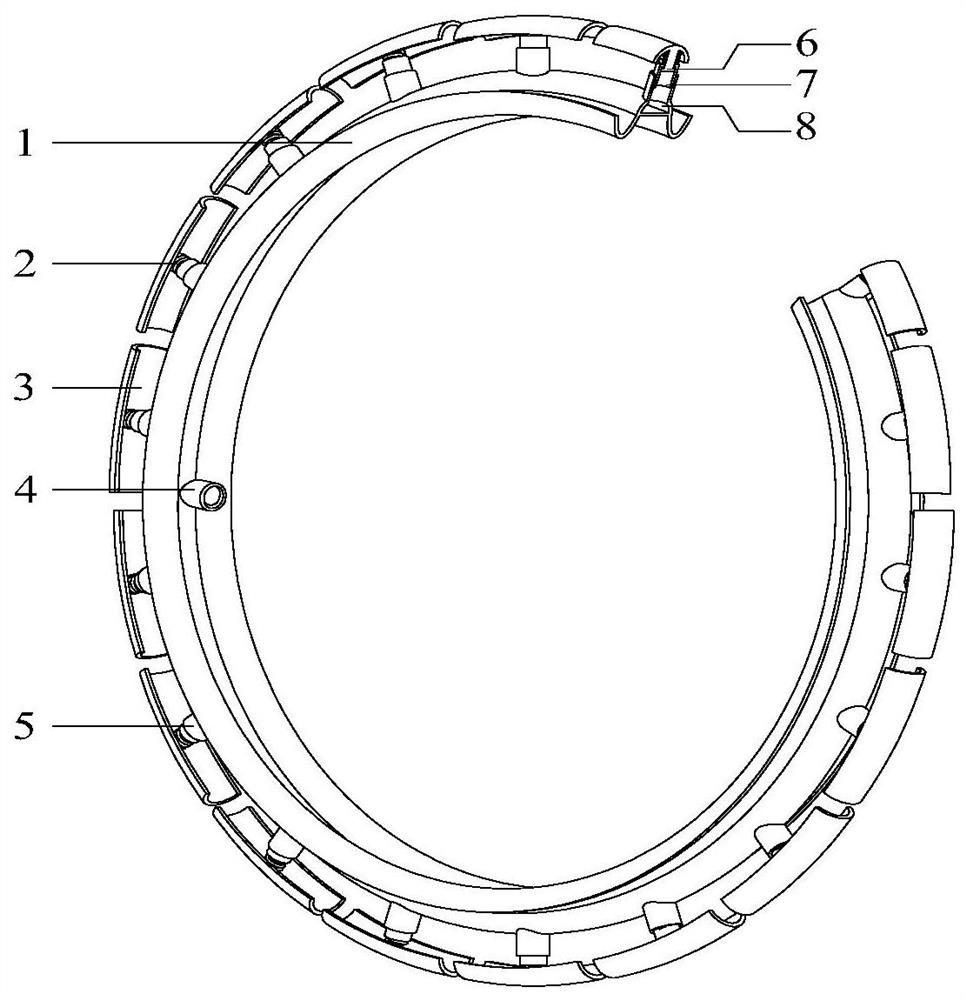

[0018] The invention provides a method for using a deep well roadway anti-impact synergistic pressure-yielding annular support. like Figure 1 to Figure 4 As shown, including bracket construction, pressure control, displacement monitoring three parts:

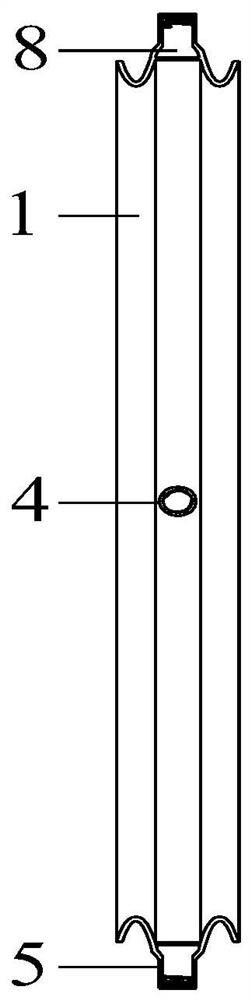

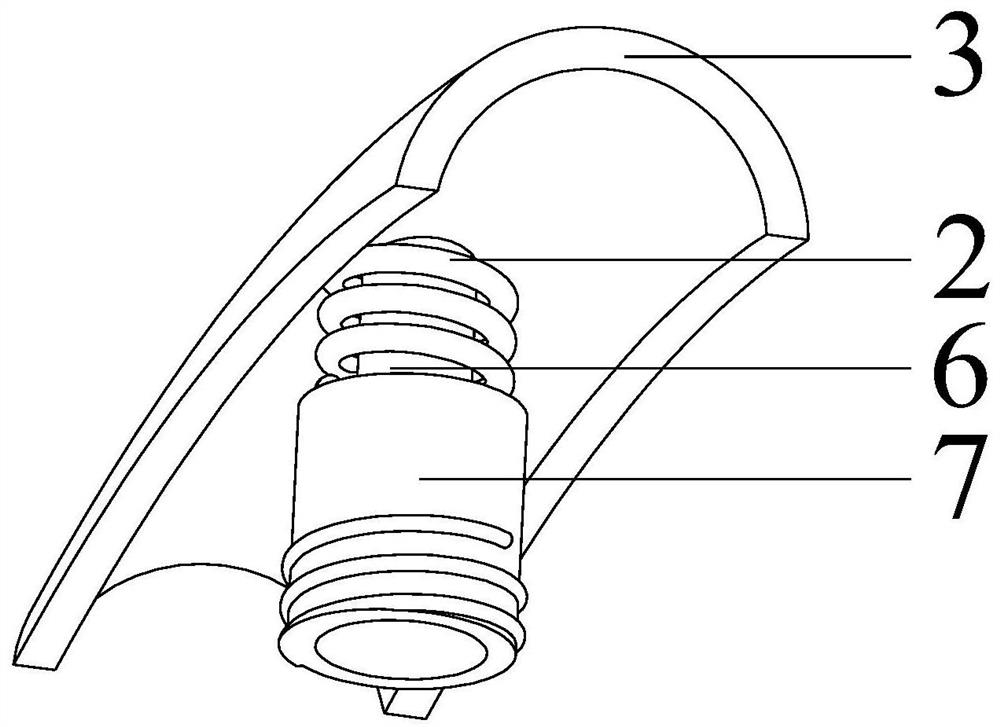

[0019] Step 1, connect the support and pressure column 6 with the connecting bearing tube 7 in turn, and let the pressure spring 2 be nested, and the support and pressure plate 3 and the support and pressure column 6 are welded and fixed, and then use this part to pass the external bearing tube. 7. The upper thread is connected with the external bearing port 5 on the periphery of the ring support 1 to form an anti-shock synergistic pressure ring support;

[0020] In step 2, the support is placed in the deep well roadway, the hydraulic pump is used to connect the hydraulic control port 4, the hyd...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap