Freezing and thawing method of freezing and thawing machine and freezing and thawing machine

A freeze-thaw and push-pull mechanism technology, applied in the field of freeze-thaw machines, can solve problems such as poor temperature uniformity, inability to monitor data, and inability to select temperature, so as to increase the speed of feeding and discharging, improve the uniformity of temperature, reduce The effect of lamellar motion stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

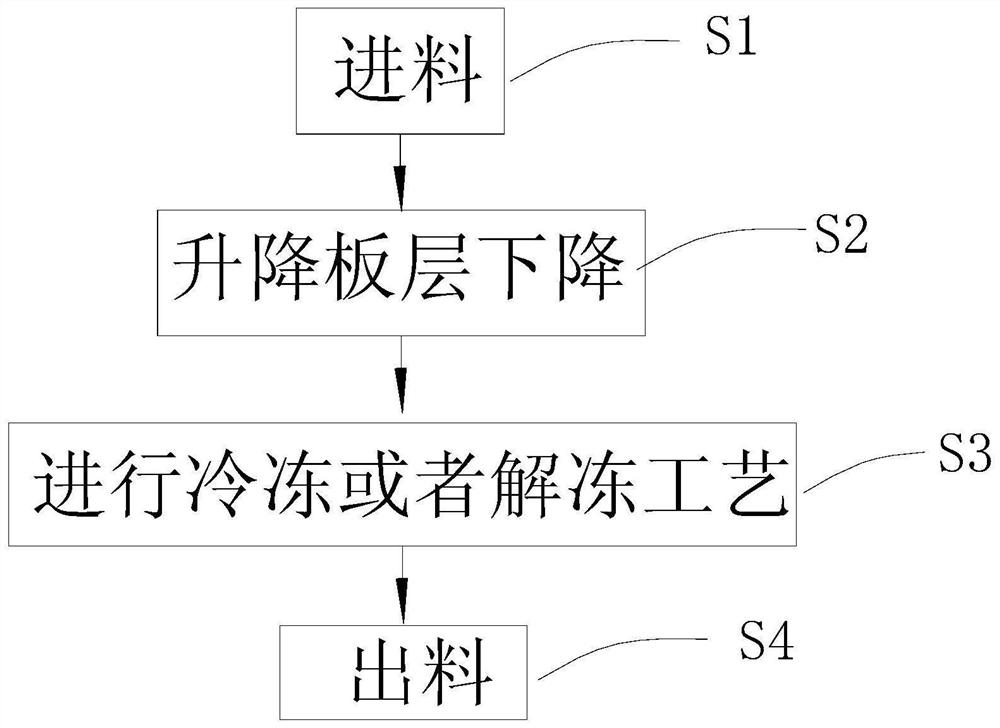

[0037] Such as figure 1 As shown, the freeze-thaw method of the freeze-thaw machine of the present embodiment may further comprise the steps:

[0038] S1. Feeding: The feeding and discharging trolley 4 is docked with the fixed plate layer 2 in the freeze-thaw chamber 1, and the push-pull mechanism 6 on the feed-in and discharge trolley 4 pushes the clamping frame 7 loaded with materials to the fixed plate in the freeze-thaw chamber on layer 2;

[0039] S2. Lowering of the lifting plate: the lifting plate 3 arranged above the fixed plate 2 is lowered, and fits with the clamping frame 7 on the fixed plate 2;

[0040] S3, performing a freezing or thawing process;

[0041] S4. Material discharge: the lifting plate layer 3 rises away from the clamping frame 7, and the push-pull mechanism 6 absorbs the clamping frame 7 through the electromagnetic component 9 and pulls the clamping frame 7 back to the feeding and discharging trolley 4.

[0042] The freeze-thaw method of the freeze...

Embodiment 2

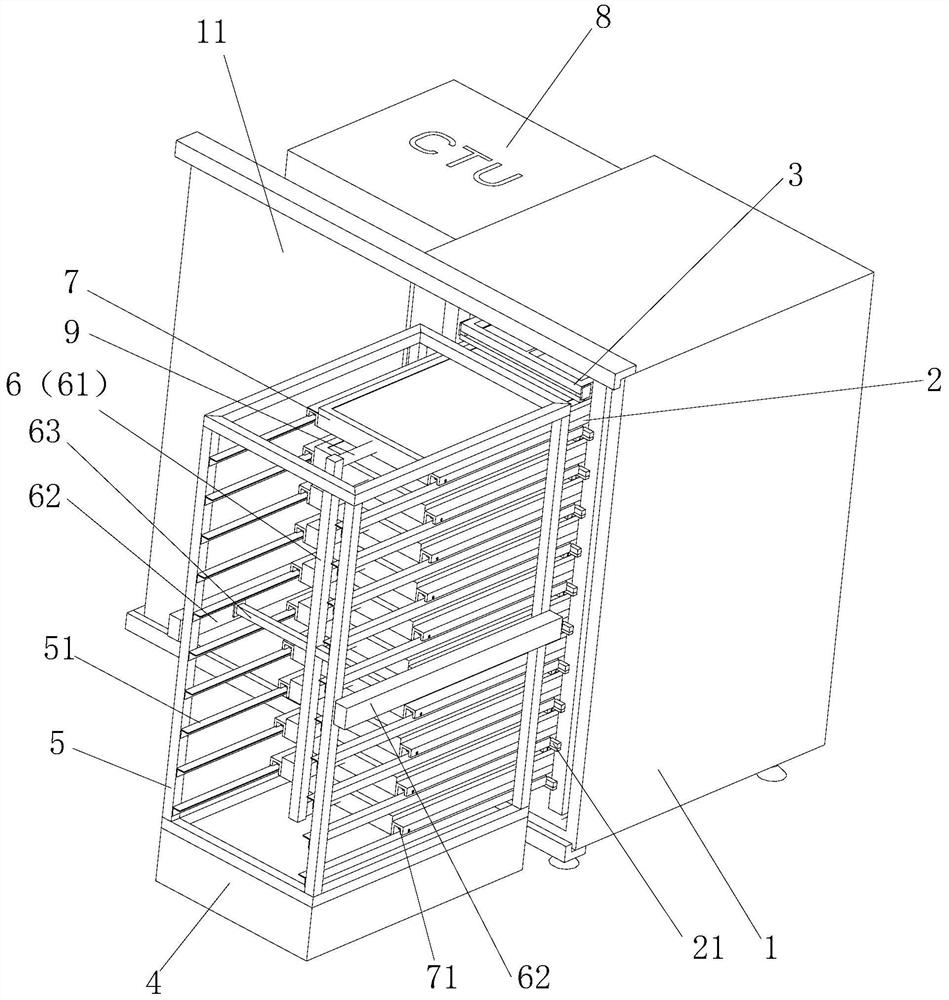

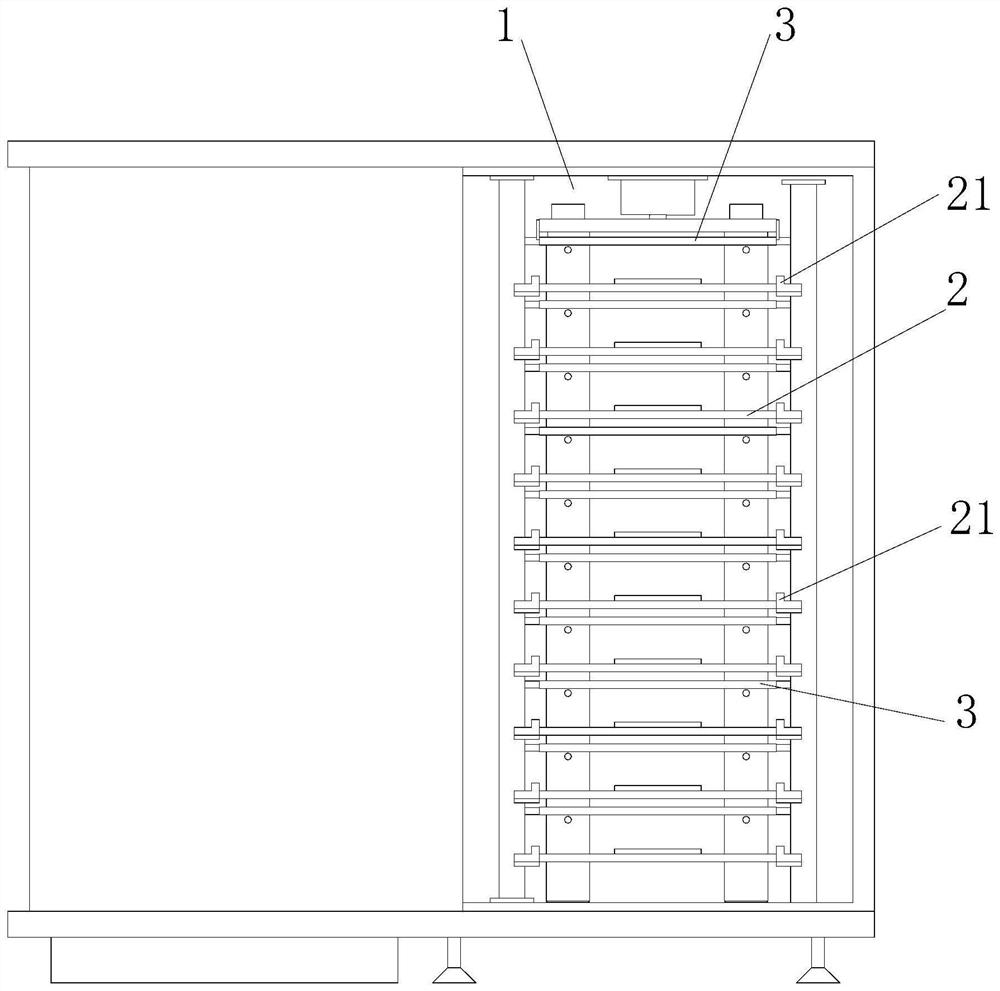

[0045] Such as Figure 2 to Figure 9 As shown, the freeze-thaw machine of the present embodiment includes a freeze-thaw chamber 1, a fixed plate 2, a lifting plate 3 and a feeding and discharging trolley 4, the fixed plate 2 is fixed in the freeze-thaw cavity 1, and the lifting plate 3 It is arranged above the fixed slab 2 and can be raised and lowered relative to the fixed slab 2. The in-out material trolley 4 includes an in-out material frame 5, a push-pull mechanism 6, and a clamping frame 7. The clamping frame 7 is arranged on the in-out material frame 5. The mechanism 6 is used to drive the clamping frame 7 to move back and forth on the input and output rack 5 and the fixed plate layer 2 , and an electromagnetic assembly 9 is arranged between the push-pull mechanism 6 and the clamping frame 7 . Wherein, the lifting plate layer 3 and the fixed plate layer 2 are hollow, and a heat conducting or cooling medium is provided inside.

[0046] When working, first feed the materi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap