Gear tooth locking type copper net quick-changing mechanism for field emission transmission electron microscopy

A technology of transmission electron microscopy and locking mechanism, which is applied in the direction of circuits, discharge tubes, electrical components, etc., can solve the problems of wrong placement of copper mesh, damage to copper mesh, cumbersome operation, etc., so as to reduce the probability of operation errors and ensure normal operation. The effect of using and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

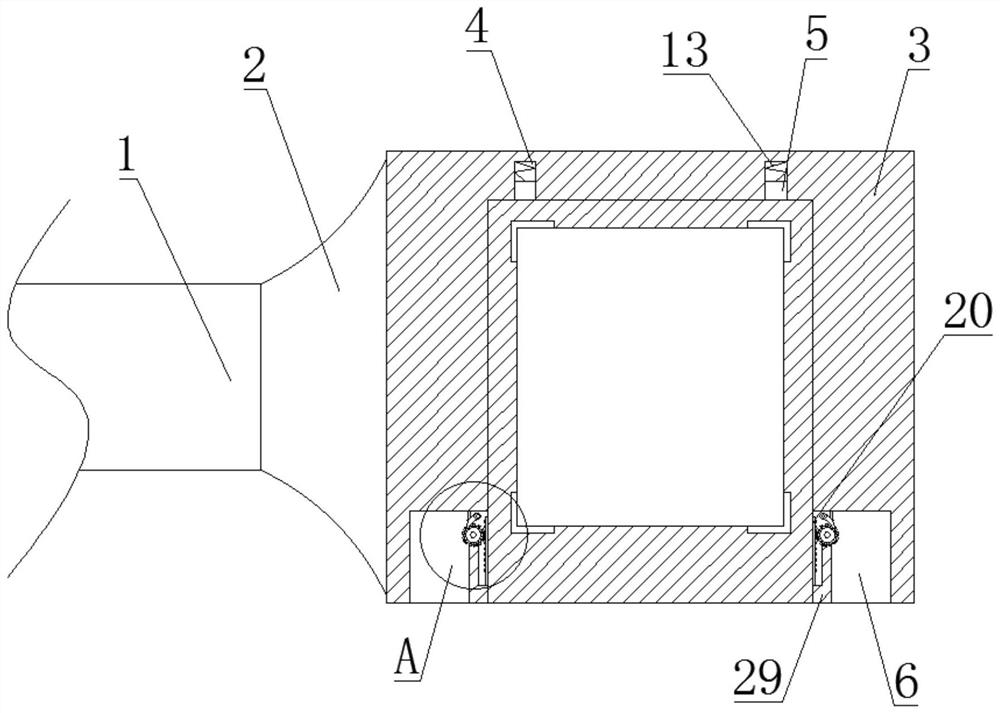

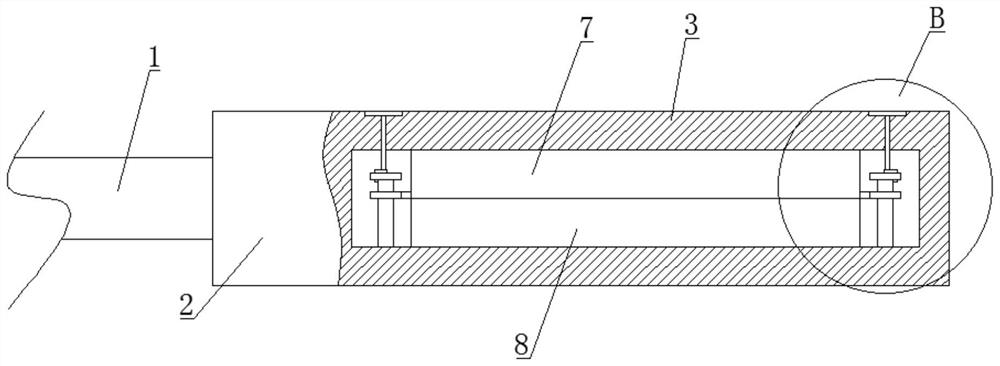

[0020] The present invention provides a tooth-locked copper mesh quick change mechanism for field emission transmission electron microscopy, which is characterized in that it includes a connection table 2, a fixed box 3, a mounting groove a4, a top block 5, a spring b13, and a copper mesh installation mechanism , the locking mechanism, the connection table 2 is set on the sample rod 1, the right end of the connection table 2 is installed with a fixed box 3, the front surface of the fixed box 3 is provided with a mounting groove b6, and the left and right ends of the rear inner wall of the mounting groove b6 are respectively opened There is an installation groove a4, a top block 5 is installed in the installation groove a4 through a spring b13, a copper mesh installation mechanism is installed in the installation groove b6, and locking mechanisms are respectively installed on the left and right sides of the copper mesh installation mechanism;

[0021] The copper mesh installatio...

Embodiment 2

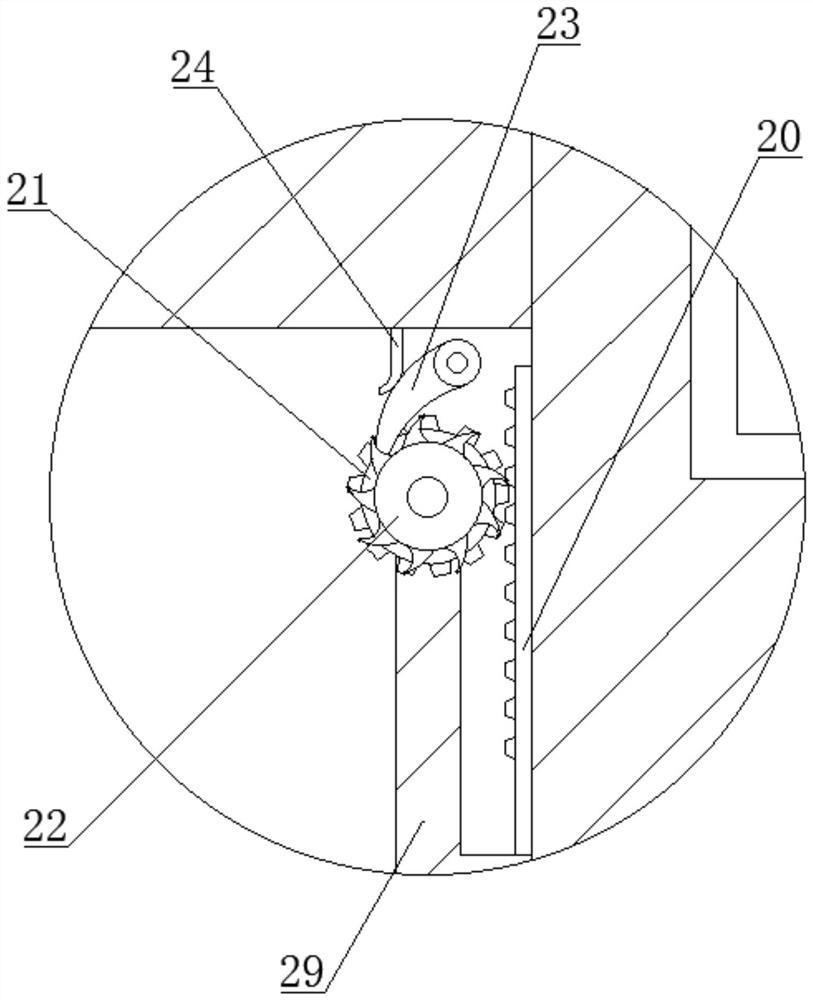

[0025] When it is necessary to disassemble the copper mesh, turn the knob b27, and the knob b27 drives the ratchet 23 to rotate through the connecting rod b26, so that the ratchet 23 is separated from the ratchet 22, so that the ratchet 22 can rotate. At this time, due to the resilience of the spring b13, the copper mesh The installation mechanism is ejected from the installation groove b6, and then the staff pulls out the copper mesh installation mechanism, and then turns the knob a18, the knob a18 drives the connecting rod a17 to rotate, and the connecting rod a17 drives the pin rod 16 to rotate. After 15 is parallel, lift the upper cover 7, the pin rod 16 is extracted from the pin hole 14 and the through groove 15, the upper cover 7 makes a circular motion with the left end as the center point, and then the staff takes out the copper mesh 10 with tweezers, and the copper mesh The dismantling work is completed;

[0026]When the copper mesh 10 needs to be installed, the staff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com