Device for separating fries according to sizes

A separation device and fish fry technology, which is applied in fish farming, application, animal husbandry, etc., can solve the problems of cumbersome operation and slow fry separation speed, and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

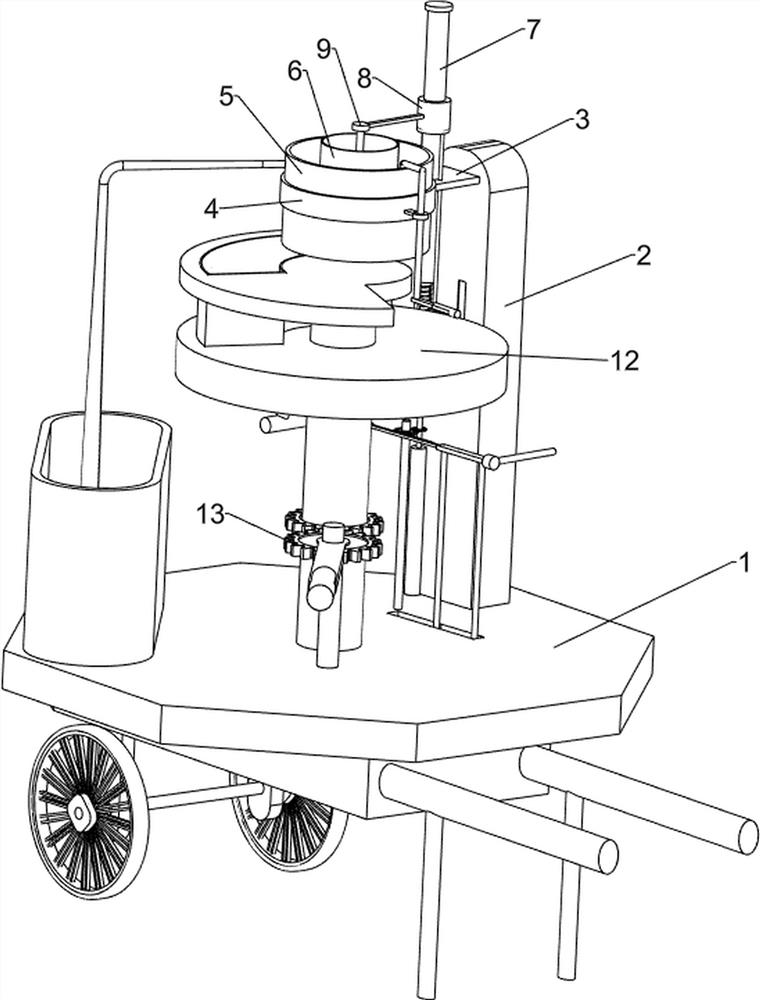

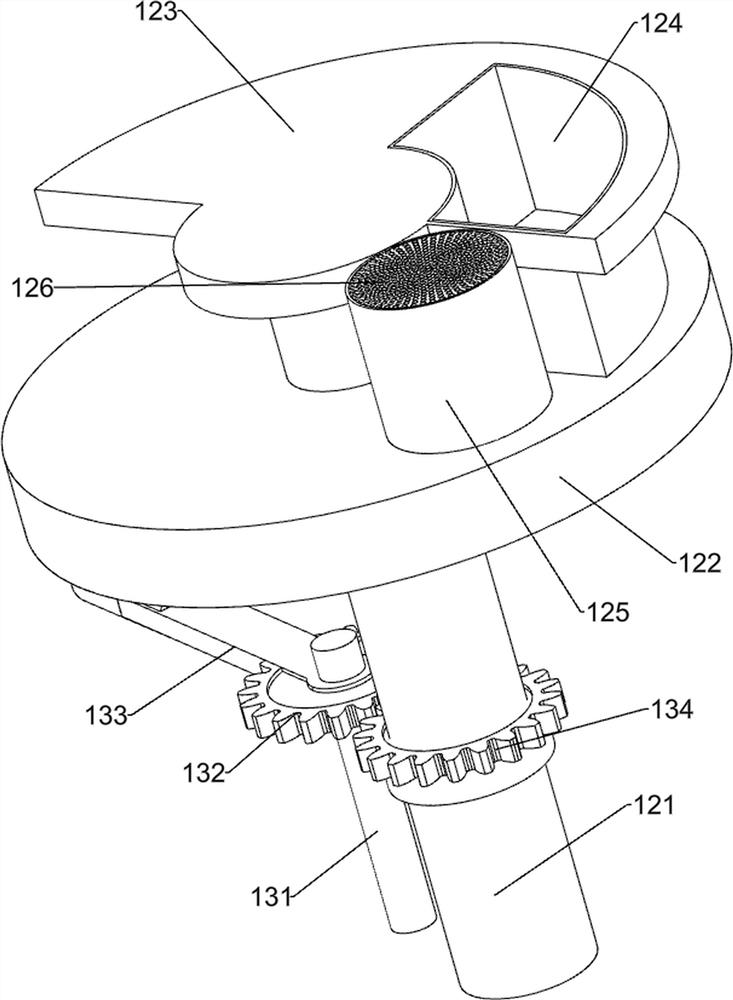

[0066] A fry size separation device such as figure 1 , figure 2 and image 3 As shown, it includes a car body 1, a fixed plate 2, a connecting plate 3, a snap ring 4, a sorting cylinder 5, a cylindrical cylinder 6, a guide rod 7, a guide sleeve 8, an L-shaped connecting rod 9, and a first screen 10 , blocking sealing plate 11, auxiliary sorting mechanism 12 and rotating mechanism 13, car body 1 is movable, and car body 1 top rear side is provided with fixed plate 2, and fixed plate 2 upper front side is provided with connecting plate 3, and connecting plate 3 front There is a snap ring 4 on the side, a sorting cylinder 5 is arranged on the inside of the snap ring 4, a cylindrical cylinder 6 is arranged in the middle of the inner bottom of the sorting cylinder 5, and a guide rod 7 is provided on the front side of the connecting plate 3, and the guide rod 7 is located on the snap ring 4 On the rear side, the upper part of the guide rod 7 is slidingly provided with a guide sle...

Embodiment 2

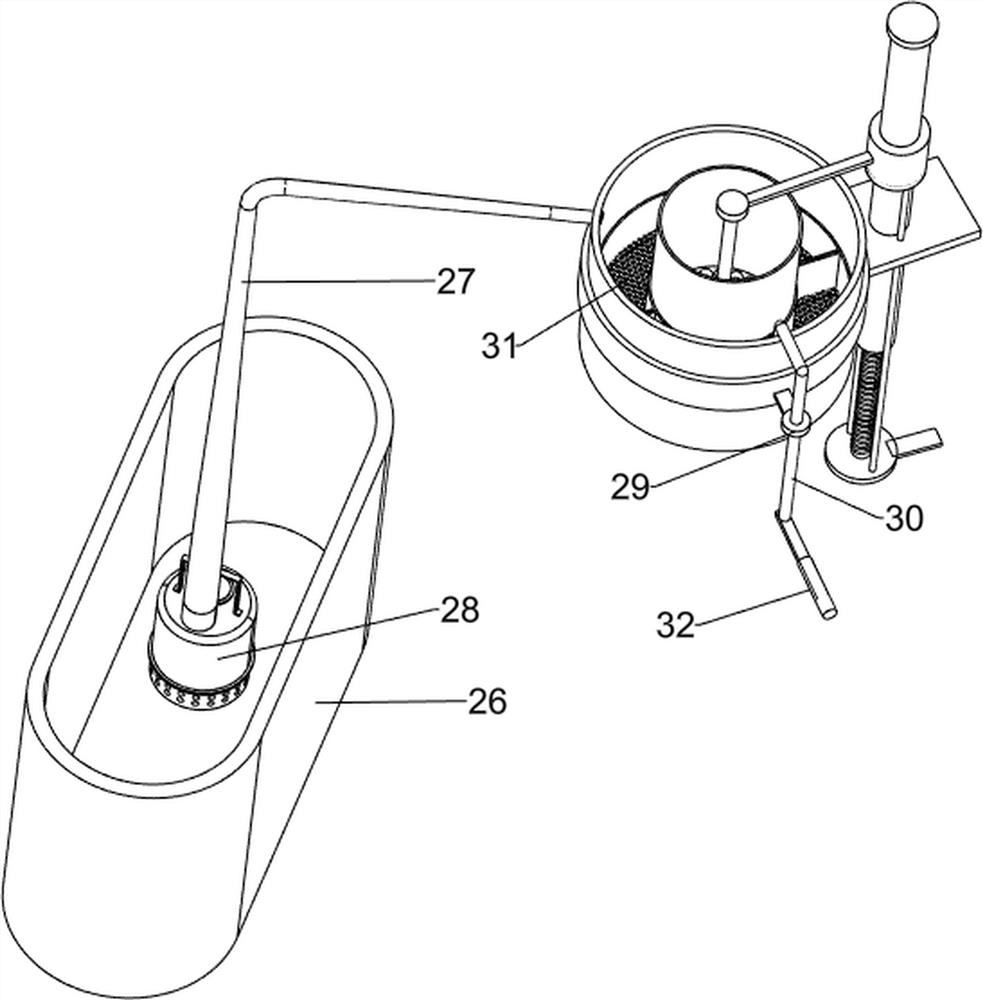

[0073] On the basis of Example 1, such as Figure 4 and Figure 5 Shown, also comprise slide bar 14, installation bar 15, straight connecting bar 16, special-shaped bar 17 and handle 18, car body 1 top rear side left and right symmetrical sliding type is provided with slide bar 14, is provided with between slide bar 14 tops Mounting rod 15, the left side of mounting rod 15 is provided with straight connecting rod 16, and straight connecting rod 16 left side is provided with special-shaped rod 17, and special-shaped rod 17 is connected with shielding sealing plate 11, and mounting rod 15 right sides is provided with handle 18.

[0074] When there is no need to block the sealing plate 11 to block the cylindrical tube 6, people manually push the handle 18 to the left, and the handle 18 drives the installation rod 15 and the sliding rod 14 to move to the left, and the installation rod 15 drives the special-shaped rod 17 to the left through the straight connecting rod 16. Left mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com