Portable lubricating oil filtering device

A filter device and lubricating oil technology, applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve the problems of reducing filtration efficiency, clogging of composite filter elements, etc., and achieve the goals of reducing air pressure, improving service life, and reducing use costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

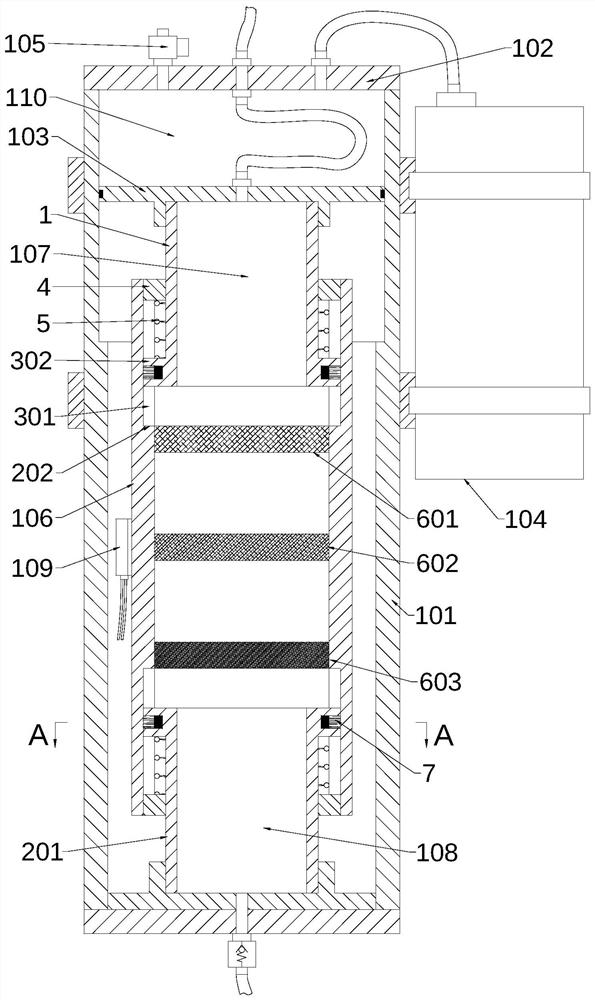

[0023] Such as figure 1 and 2 As shown, a portable lubricating oil filter device provided by the present invention includes: an outer piston cylinder, a filter cylinder and a vibration generator 109, the outer piston cylinder includes an outer cylinder body 101, an outer cylinder cover 102 and a linkage piston 103, and the outer piston cylinder The top opening of the cylinder body 101 is sealed and fixedly connected with the outer cylinder head 102. The outer cylinder head 102 is provided with an air inlet and an exhaust port. The air inlet is connected with an air source device 104, and the air source device 104 is electrically connected There is a controller, the controller is electrically connected to a power supply device, the exhaust port is connected to an electromagnetic switch valve 105, the electromagnetic switch valve 105 is electrically connected to the controller, and one end of the linkage piston 103 is connected to the top of the outer cylinder body 101 The inne...

Embodiment 2

[0028] On the basis of Embodiment 1, in order to prevent the vibration generated by the vibration generator 109 from being transmitted to the outer cylinder 101 through the filter cylinder 106, thereby effectively reducing the noise generated when the device is in operation.

[0029] Such as figure 1 As shown, wherein, a filter cylinder piston 201 is also provided between the filter cylinder body 106 and the outer cylinder body 101, one end of the filter cylinder piston 201 is fixedly connected to the bottom inner wall of the outer cylinder body 101, and the other end of the filter cylinder piston 201 is connected to the inner wall of the bottom of the outer cylinder body 101. The bottom inner wall of the filter cylinder 106 is sealed and slidingly connected, and the top and bottom inner walls of the filter cylinder 106 are provided with a limit spacer 202, and the limit spacer 202 at the top of the filter cylinder 106 is used to limit the movement of the linkage piston. 103, ...

Embodiment 3

[0032] On the basis of Embodiment 2, in order to prevent the vibration generated by the vibration generator 109 from causing the filter cylinder 106 to rotate and cause the pipeline to be entangled.

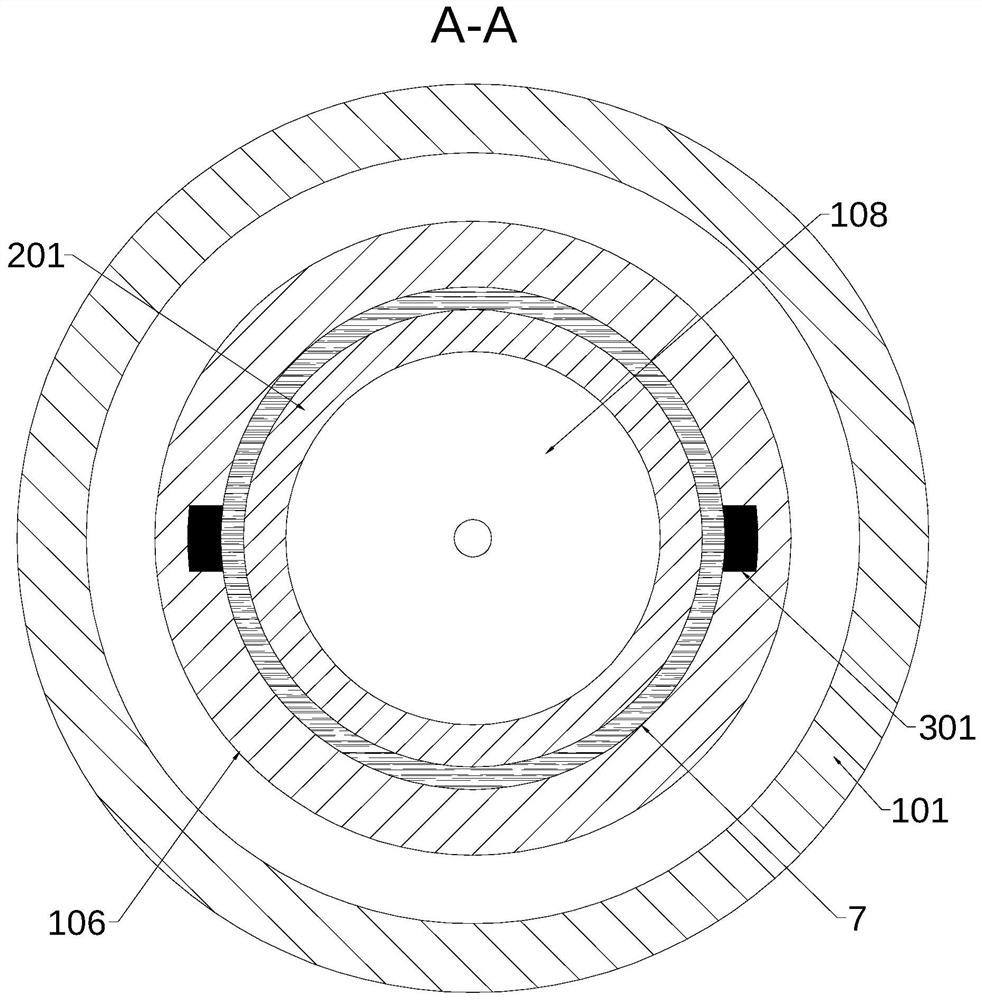

[0033] Such as figure 1 and 2As shown, wherein, the top inner wall and the bottom inner wall of the filter cylinder 106 are provided with a guide groove 301 along the axial direction of the filter cylinder 106, and the linkage piston 103 and the filter cylinder piston 201 are both provided with a guide block 302. The guide block 302 of the piston 103 is in sealing and sliding connection with the guide groove 301 on the top inner wall of the filter cylinder body 106 , and the guide block 302 of the filter cylinder piston 201 is in sealing and sliding connection with the guide groove 301 on the inner wall at the bottom end of the filter cylinder body 106 .

[0034] By setting the guide block 302 and the guide groove 301, the linkage piston 103 and the filter cylinder piston 201 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com