Production device for blank body

A technology for producing a device and an embryonic body, which is applied in the field of wool fiber handicrafts, embryonic bodies or parts production of ornaments, can solve the problems of time-consuming, easily damaged staff, structural strength of foam embryos, damage to appearance and shape, etc. Production quality, improved rolling effect, improved structural strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

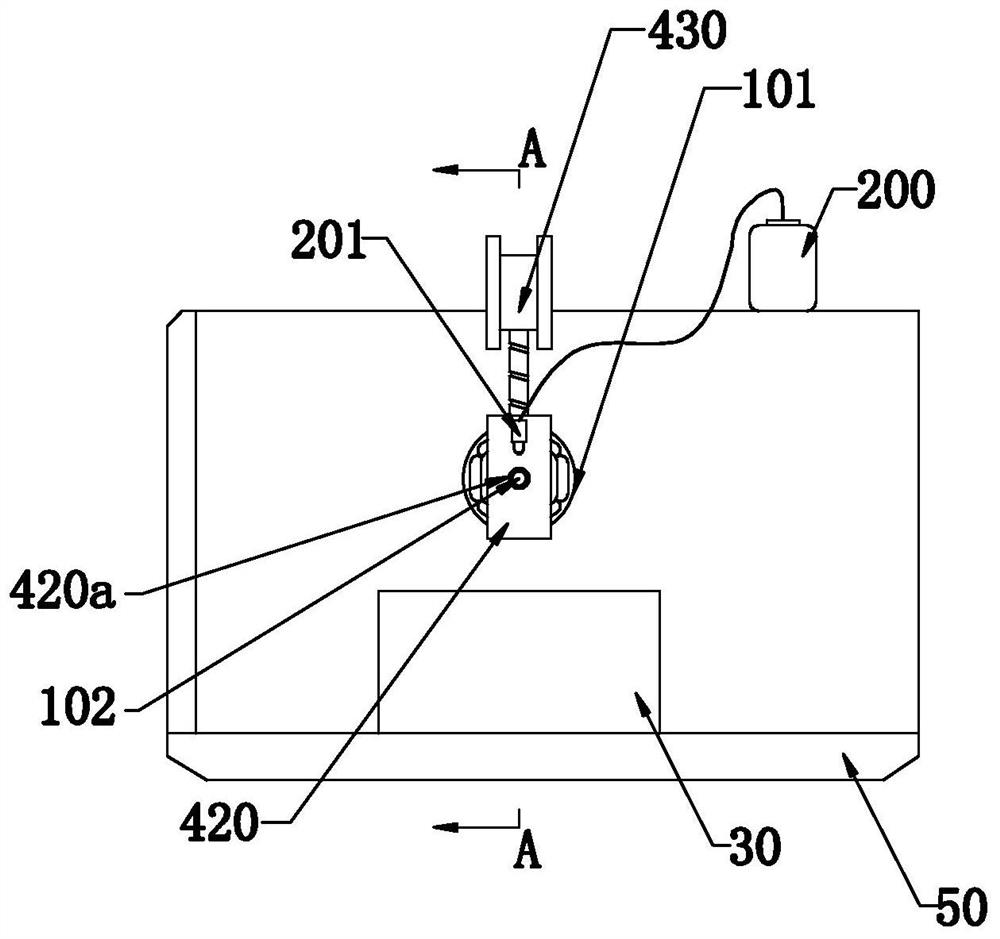

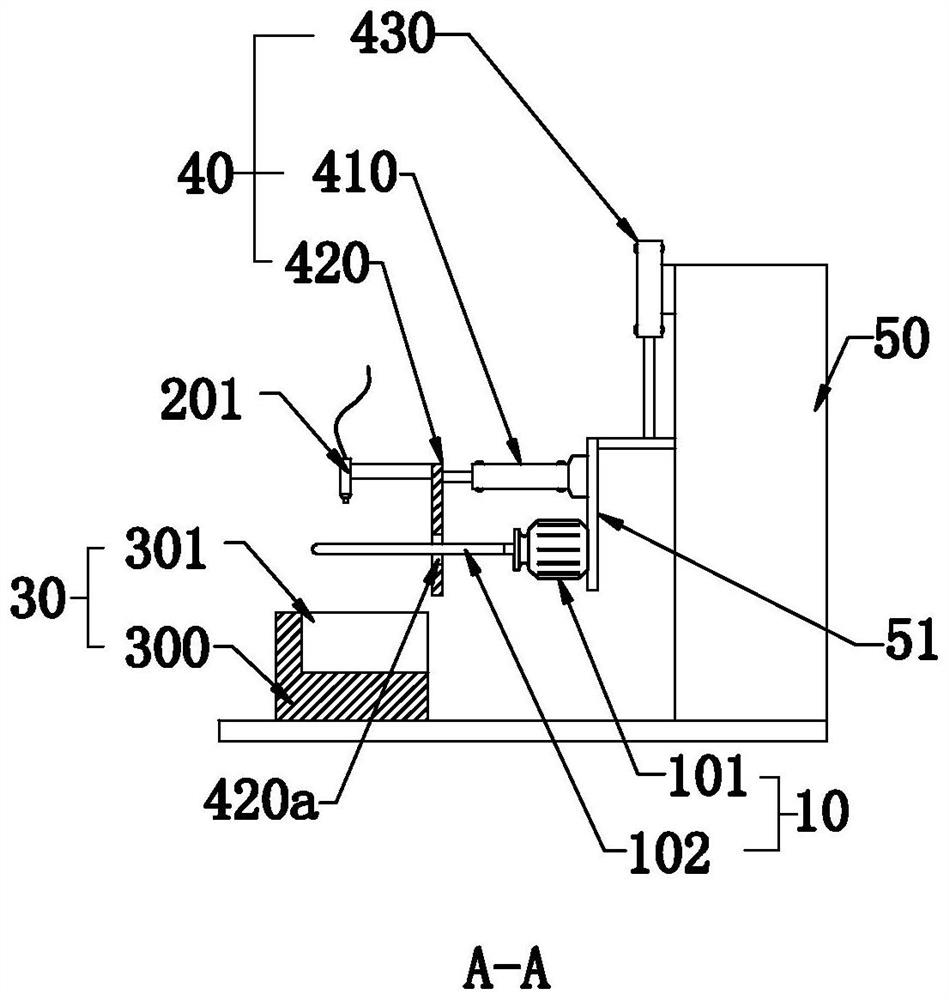

[0031] like Figure 1-Figure 2 As shown, the present invention discloses a production device for an embryo body. In a specific embodiment of the present invention, it includes a rolling assembly 10, a sizing assembly 20, and a mold 30; wherein, the mold 30 has at least one forming area, and the The rolling component 10 has at least one rotatable rolling part, and the rolling part drives the material to knead in the forming area and forms an embryo body. The sizing component 20 is used to supply the forming area or the rolling part. glue.

[0032] In a specific embodiment of the present invention, the mold 30 includes a mold body 300 and a tank body 301 which is arranged on the mold body 300 and can constitute a molding area. The first driver 101 controls the rotating pickup roller 102 .

[0033] In a specific embodiment of the present invention, the gluing component 20 includes a gluing source 200 and a nozzle 201 for supplying gluing to the forming area or rolling part 100 ...

Embodiment 2

[0043] Embodiment 2, the difference with embodiment 1 is that

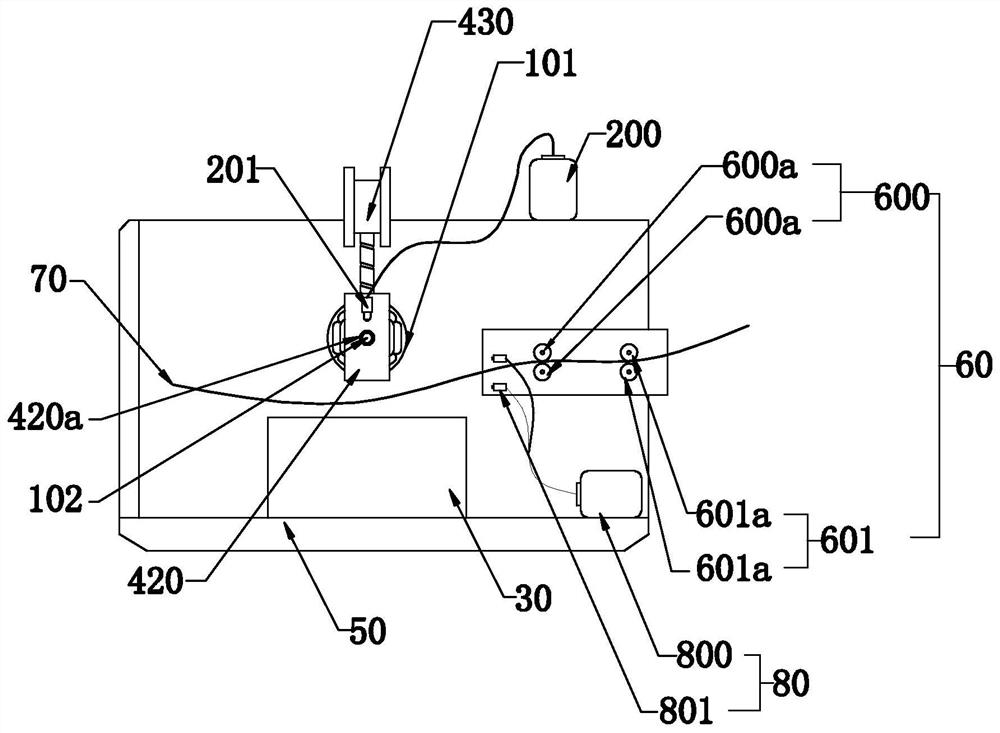

[0044] like image 3 As shown, in the specific embodiment of the present invention, it also includes at least one set of feeding assembly 60 for supplying materials to the molding area, and the feeding assembly 60 includes at least two rotatable conveying rollers arranged in gaps, adjacent The feeding area is formed between the conveying rollers.

[0045] In a specific embodiment of the present invention, the feeding assembly 60 includes a first feed roller set 600 and a second feed roller set 601, and the first feed roller set 600 and the second feed roller set 601 can be controlled by the fourth driver at Rotate in differential mode or constant speed mode;

[0046] In the differential speed mode, the fourth driver controls the first feed roller set 600 and the second feed roller set 601 to rotate at different speeds, and stretch or break the raw material 7;

[0047] In the constant speed mode, the fourth driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com