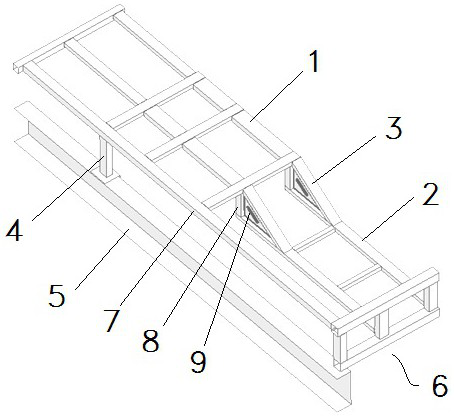

Front passenger car and front floor framework thereof

A front floor and bus technology, applied to the upper structure of the bus, vehicle parts, upper structure sub-assembly, etc., can solve the driver's safety threat and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

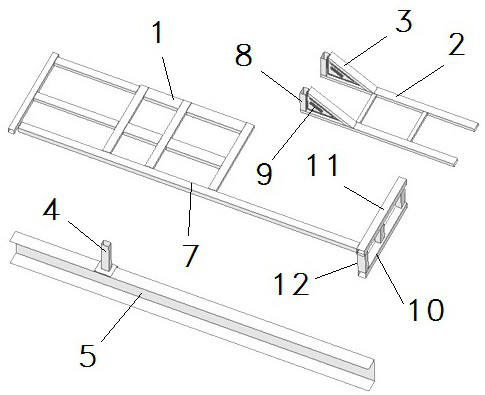

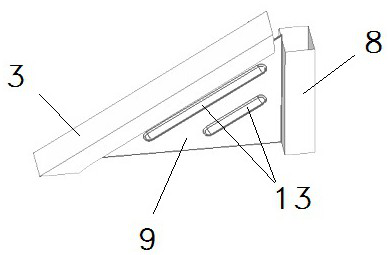

Method used

Image

Examples

Embodiment 2

[0071] The specific embodiment 2 of the front floor frame of the front passenger car of the present application: the difference between this embodiment and the embodiment 1 is that no erecting load-bearing members and force-transmitting longitudinal beams are provided, and the oblique connecting beams and stress dispersing plates are dispersed and connected. The stress at the beam, the stress dispersing structure consists only of connecting vertical beams and stress dispersing plates.

specific Embodiment 3

[0072] The specific embodiment 3 of the front floor frame of the front passenger car of the present application: the difference between this embodiment and the embodiment 1 is that the connecting vertical beams and the stress dispersing plates are not provided, and the vertical load-bearing members and the force-transmitting longitudinal beams are dispersed to connect the inclined beams. The stress at the beam, the stress dispersion structure is only composed of the vertical bearing member and the force transmission longitudinal beam.

specific Embodiment 4

[0073] The specific embodiment 4 of the front floor frame of the front passenger car of the present application: the difference between this embodiment and the embodiment 1 is that no connecting vertical beams are provided, and the oblique connection is dispersed by means of the vertical load-bearing members, the force-transmitting longitudinal beams and the stress dispersion plate. stress on the beam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com