An automatic packaging production line for emulsified explosive rods

An automatic packaging and emulsified explosive technology, which is applied in packaging and other directions, can solve the problems of manual assistance, material jams, and irregular drug strips in measuring the number of medicine strips, so as to facilitate the calculation of quantities and neat output, accurate quantity calculation, and medicine strips The effect of tidy stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

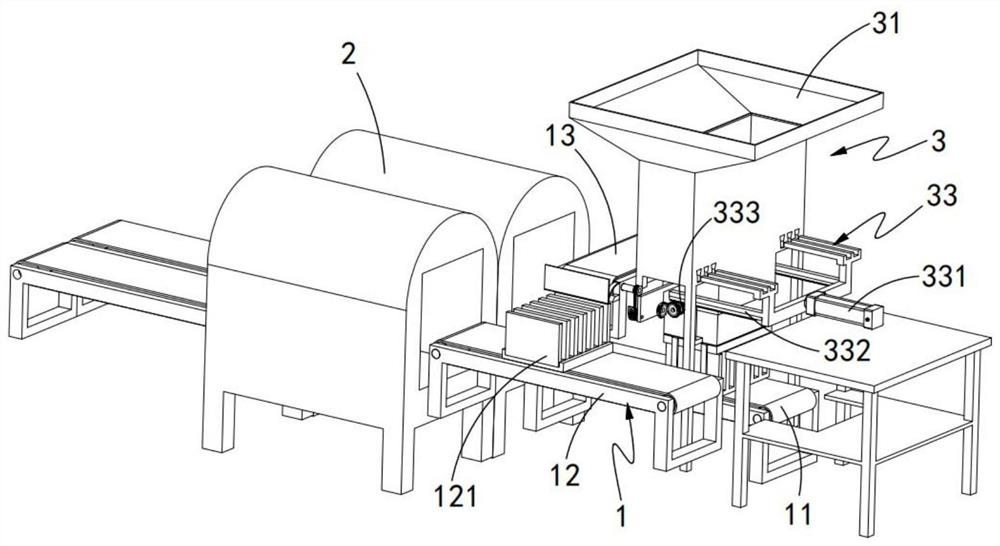

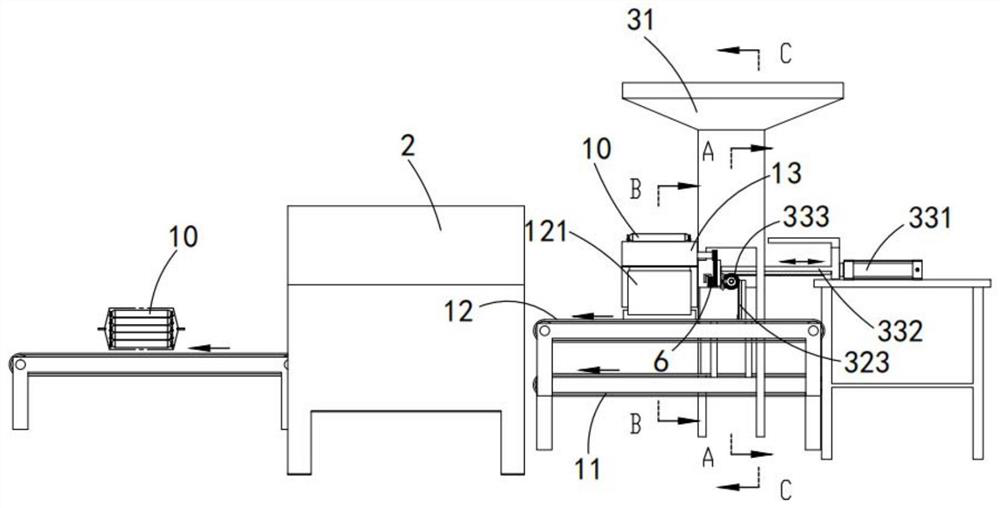

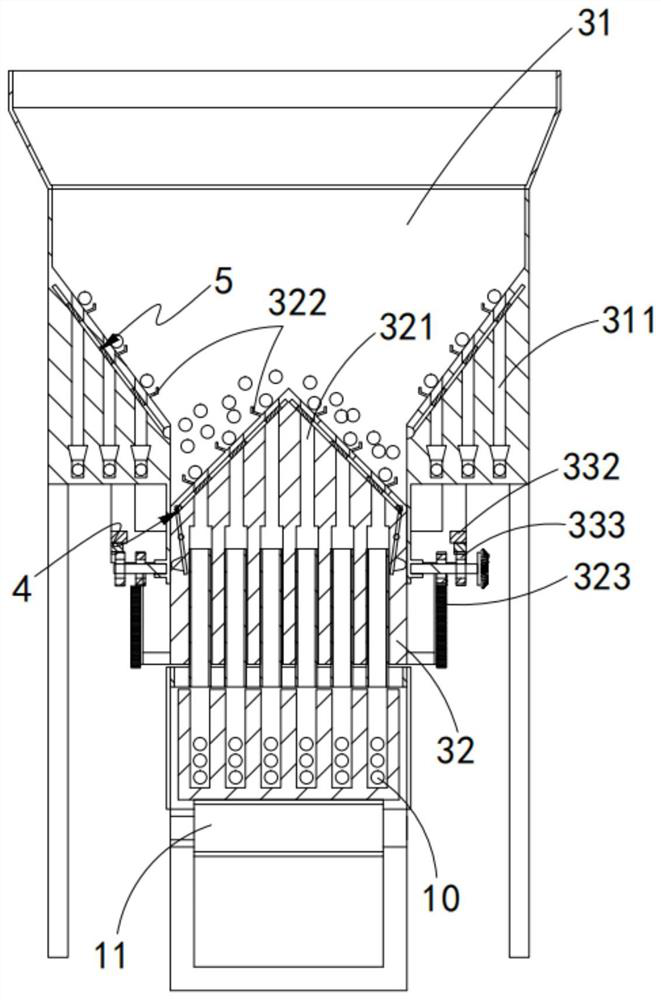

[0038] Such as Figure 1 to Figure 6 As shown, an automatic packaging production line for emulsified explosive rods includes a transmission component 1 and a bag sealing device 2 arranged at the transmission end of the transmission component 1. It is characterized in that it also includes a sorting device 3, which is arranged on the The front end of the conveying assembly 1, the finishing device 3 sorts and arranges the strips of medicine and then transfers them to the bag sealing device 2 for packaging by the conveying assembly 1; The organizing unit 32 and the drive assembly 33 that drives the lifting movement of the organizing unit 32, the interior of the organizing unit 32 is provided with a number of conduction channels 321, and the vertical reciprocating movement of the organizing unit 32 moves the The explosive rods 10 stored in the hopper 31 are neatly output.

[0039] Further, the top surface of the strip unit 32 is set in the shape of a ridge with a high center and ...

Embodiment 2

[0042] Figures 7 to 11 It is a structural schematic diagram of an automatic packaging production line for emulsion explosive rods of the present invention; wherein the same or corresponding parts as in Embodiment 1 adopt the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the description and embodiment are hereinafter 1 point of difference. The difference between this embodiment 2 and embodiment 1 is:

[0043] In this embodiment, the drive assembly 33 includes a cylinder 331, a pushing frame 332 and a reversing gear 333, the pushing frame 332 is provided with a rack meshed with the reversing gear 333, and the cylinder 331 drives the The pushing frame 332 reciprocates, and the two sides of the organizing unit 32 are provided with a spur rack 323 meshing with the reversing gear 333, and the reversing gear 333 drives the organizing unit 32 to go up and down.

[0044] Further, a secondary channel 311 is also included, and the secondary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com