Thermal transfer ribbon printer for test tubes

A technology of printers and printing mechanisms, applied in typewriters, printing, labeling machines, etc., can solve problems such as inability to realize automatic operations, inability to popularize chemical laboratories, and information loss, etc., to achieve convenient and quick paper replacement, long-term storage, and reduced corners effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation of the test tube carbon ribbon printer of the present invention will be described in detail below in conjunction with the accompanying drawings.

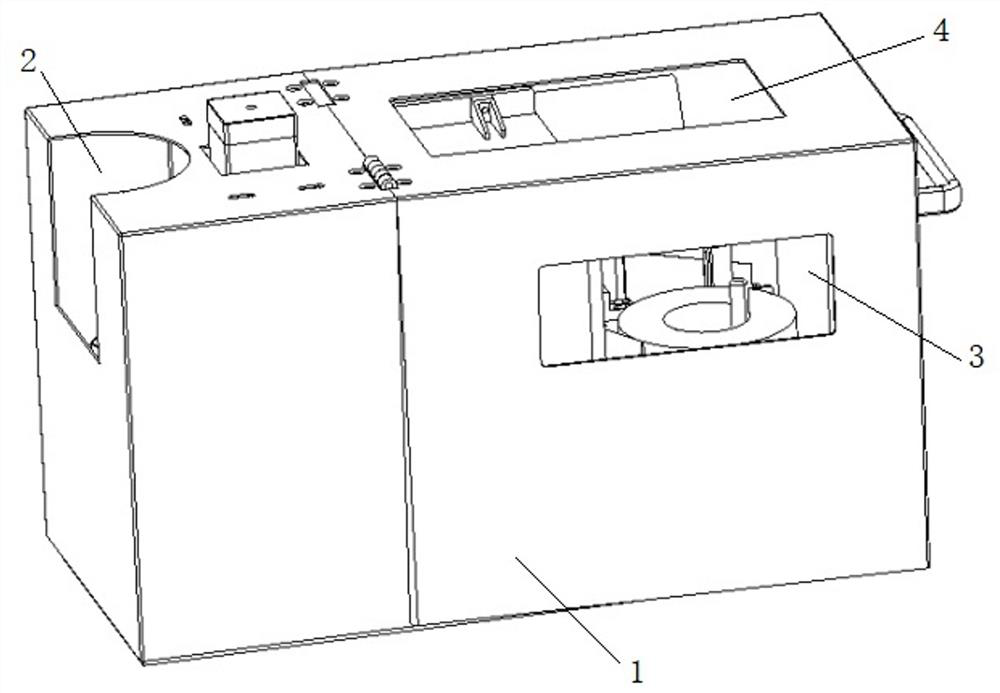

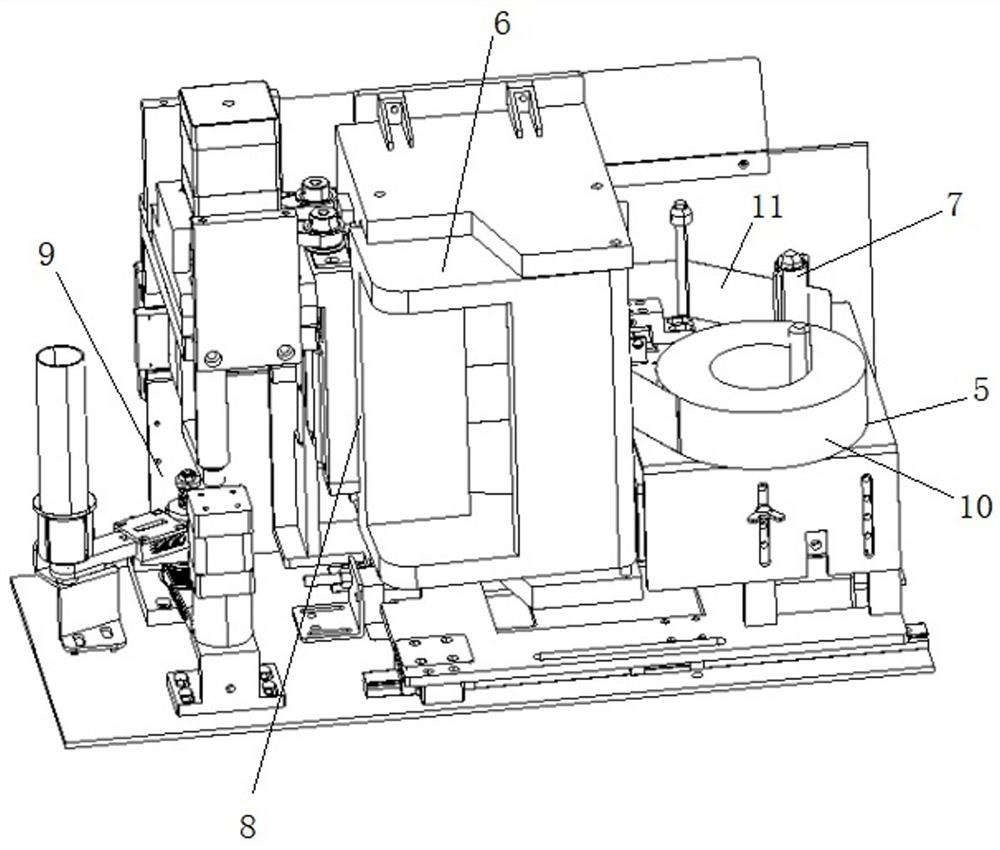

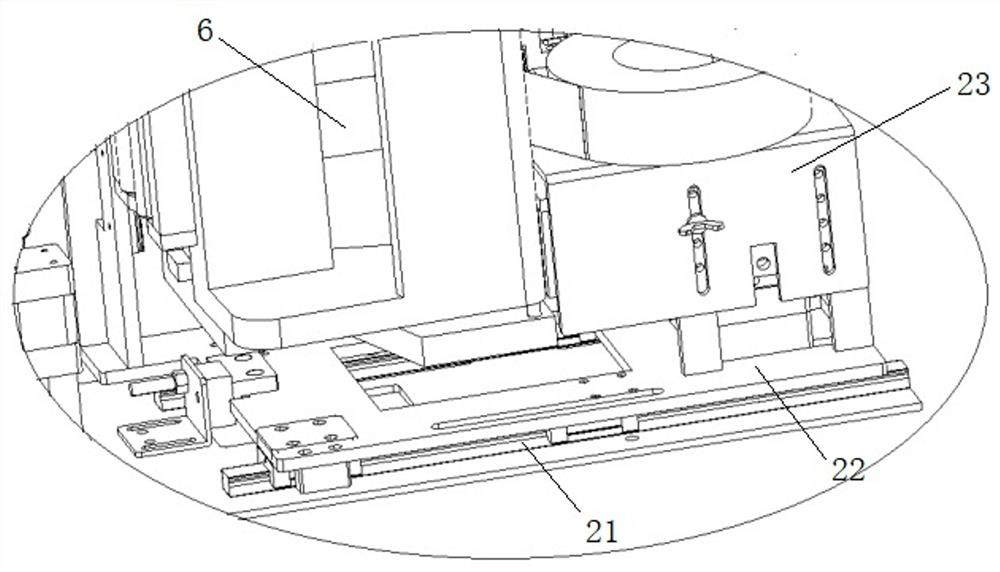

[0044] See attached figure 1 , the shell 1 of the test tube carbon ribbon printer is divided into two parts, which are respectively the part on the test tube delivery side and the part on the printing side. Both sides can be opened separately for maintenance. A test tube input port 2 is provided on the test tube conveying side, which is convenient for inputting and taking out the test tube, and the size of the test tube input port 2 is suitable for the operation of the mechanical arm. On the printing side, there is an inlet 4 for the ribbon paper roll at the top, an observation window 3 is arranged in the front, and an upwardly opened sliding door is provided for the installation and maintenance of the printer.

[0045] The printer of the present invention uses a commercially available general pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com