Optimal design method for low-speed magnetic gear of high-power wind-electromagnetic gearbox

A technology of optimized design and magnetic gear, which is applied in the field of optimal design of low-speed gears of wind power gearboxes and low-speed magnetic gears of high-power wind electromagnetic gearboxes. Work efficiency, improve transmission accuracy, reduce the effect of angle error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in further detail below in conjunction with the accompanying drawings.

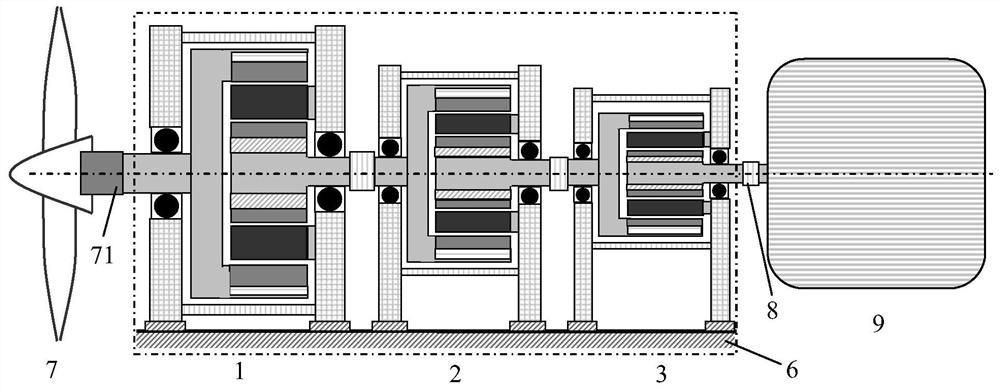

[0053] Such as figure 1 As shown, the topological structure of the doubly-fed wind power generation system of the present invention includes the wind wheel 7 and its main shaft 71, the magnetic gearbox of the present invention, the generator coupling 8 and the doubly-fed wind power generator 9;

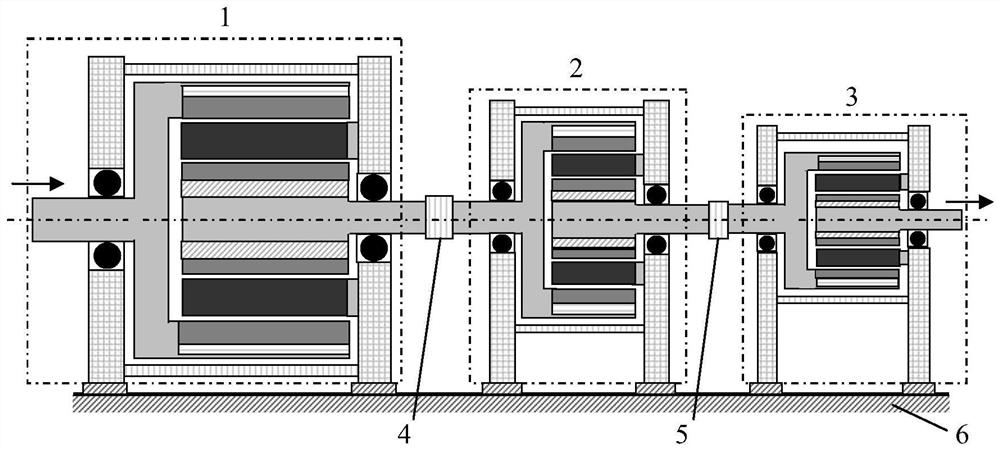

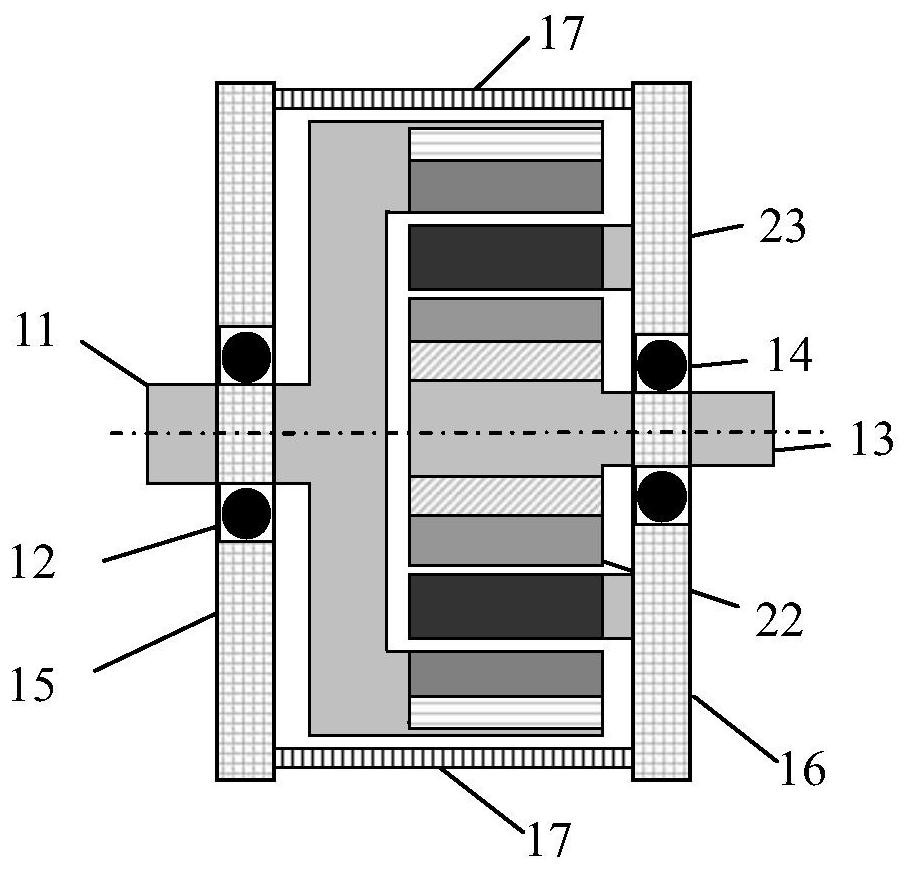

[0054] Such as figure 1 , figure 2 As shown, the magnetic gear box of the present invention includes: a low-speed magnetic gear 1, a first coupling 4, a medium-speed magnetic gear 2, a second coupling 5, a high-speed magnetic gear 3, and a base 6. The driving shaft 11 of the low-speed magnetic gear 1 is connected to the main shaft 71 of the wind wheel 7; the driven shaft 13 of the low-speed magnetic gear 1 is connected with the driving shaft of the medium-speed magnetic gear 2 through the first coupling 4; the medium-speed The driven shaft of the magnetic gear 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com