Shoe washing method and shoe washing device

A technology for washing shoes and shoes, which is applied in the field of shoe washing devices and mechanical shoe washing for realizing the shoe washing method, can solve the problems of reduced washing capacity, high cost, and high labor intensity, so as to ensure the washing quality and prevent radial Shaking, the effect of reducing the weight of the drum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The device of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

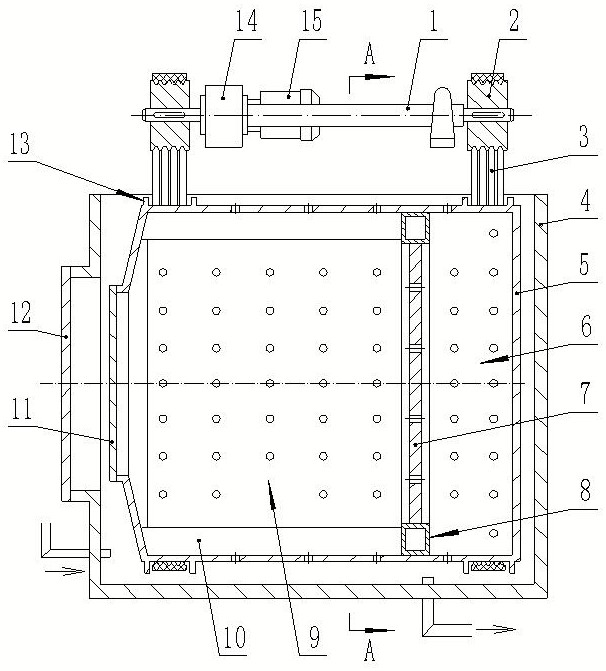

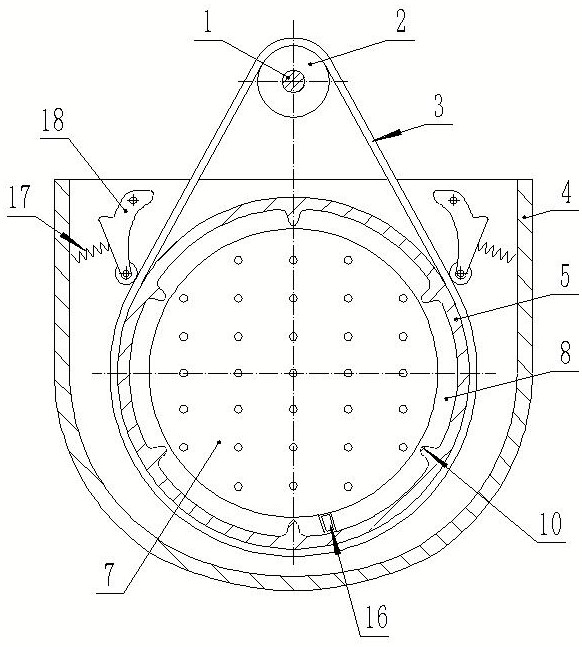

[0041] The inventive device such as Figure 1~4 As shown: the rotating shaft 1 is installed on the frame (not shown in the figure) through the bearing (not shown in the figure), and the motor 15 fixed on the frame drives the rotating shaft 1 to rotate through the reducer 14, and the two ends of the rotating shaft Pulleys 2 are respectively fixed. Below the rotating shaft 1 is a water tank 4 fixed on the frame, and the drums 5 are horizontally suspended in the water tank 4 by two belts 3 correspondingly connected with the belt pulley 2 respectively.

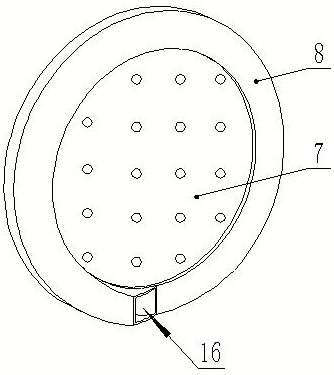

[0042] The wall of the drum 5 is distributed with some water holes (not marked in the figure), and the transfer device that divides its interior into a washing compartment 9 and a storage compartment 6 is fixed in the drum. The transfer device is composed of a spiral tube 8 welded t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com