Connecting structure and connecting method for components of prefabricated slab culvert

A prefabricated assembly and connection structure technology, which is applied in the direction of buildings and road bottom layers, can solve the problems affecting the construction progress of highway projects, the strength is not fully formed, and the cracks of culvert components are damaged, so as to shorten the construction period, simplify the composition, and reduce the project cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

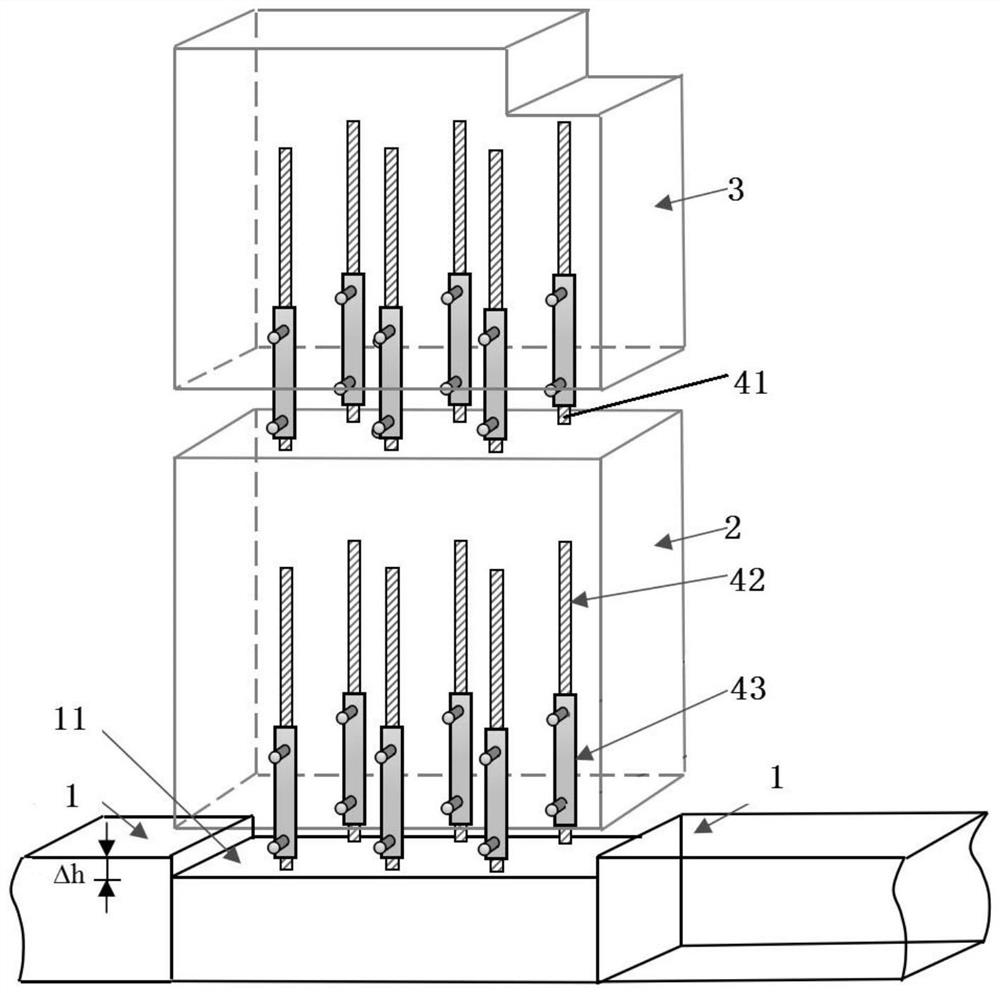

[0039] Attached below Figure 1-7 , the specific implementation of the present invention will be described in detail, but it should be understood that the protection scope of the present invention is not limited by the specific implementation. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

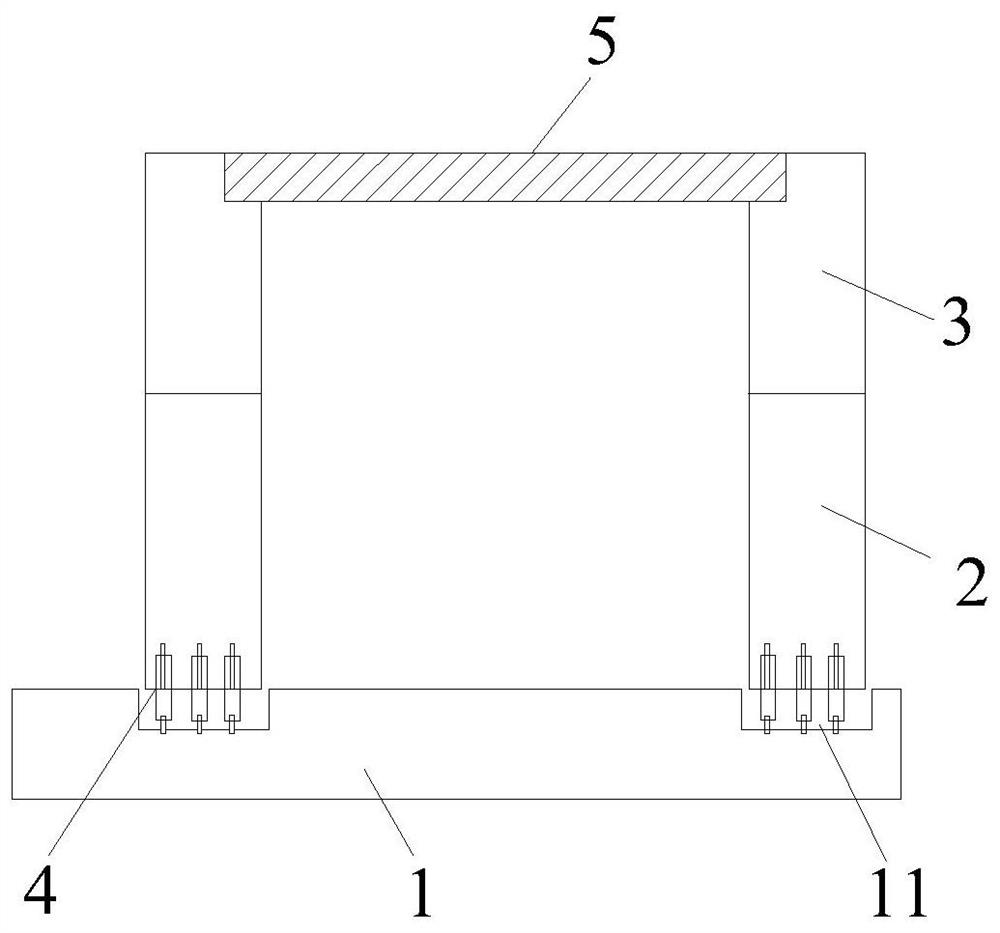

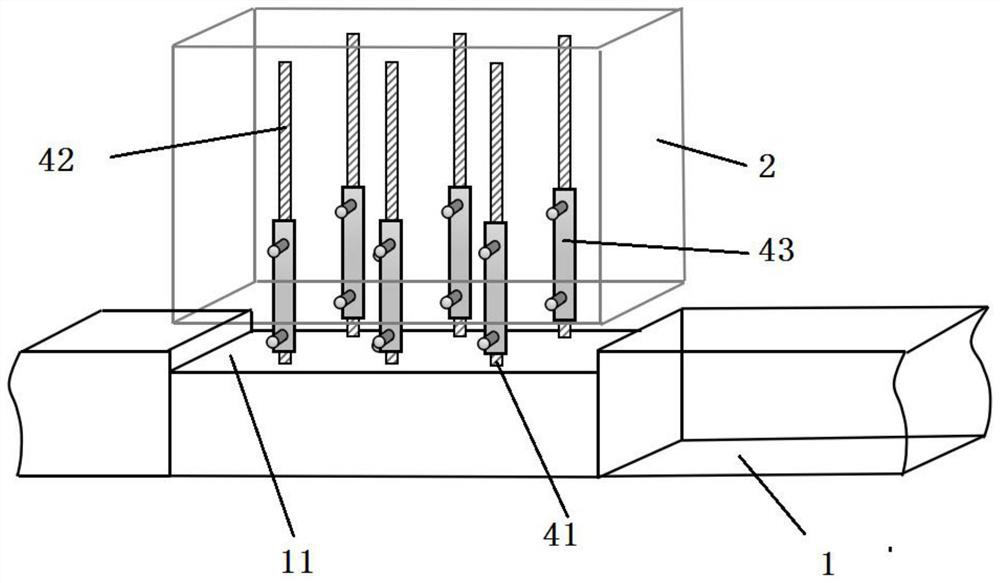

[0040] The present invention provides a prefabricated assembled cover covering the connection structure and connection method of each component, including:

[0041] The culvert foundation 1, the top surface is provided with a groove 11 for accommodating the bottom of the side wall;

[0042] The lower part 2 of the culvert side wall is distributed on both sides of the culvert foundation 1, and its bottom is located in the groove 11;

[0043] culvert side wall sections 3 on top of each culvert side wall lower section 2;

[0044...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com