Cage for rolling bearing and rolling bearing

A rolling bearing and cage technology, applied in the field of cages, can solve the problems that the cage does not utilize high speed and high load, the axial beam of the cage is broken, and the cage is melted, etc., so as to prevent excessive compression or tension, prevent high speed and High load, reduced tangential load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

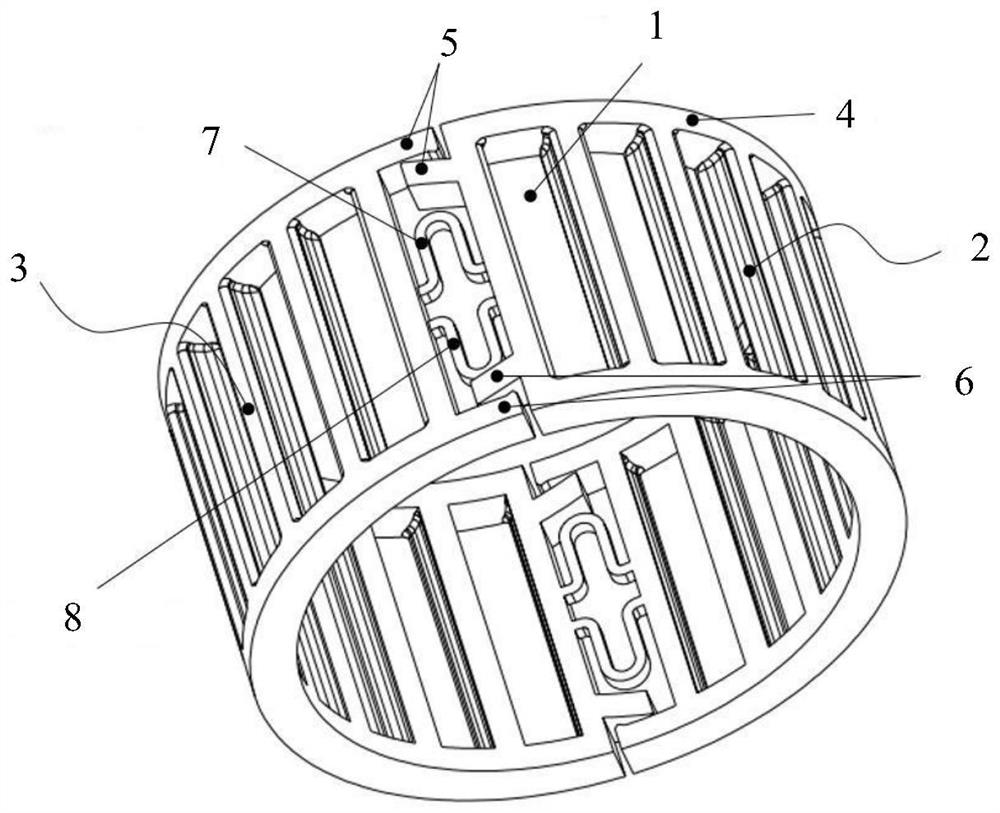

[0026] figure 1 A perspective view of a cage according to a preferred embodiment is shown. In this embodiment, the cage is configured as a nylon cage for needle bearings. The cage is produced in one piece by a molding process.

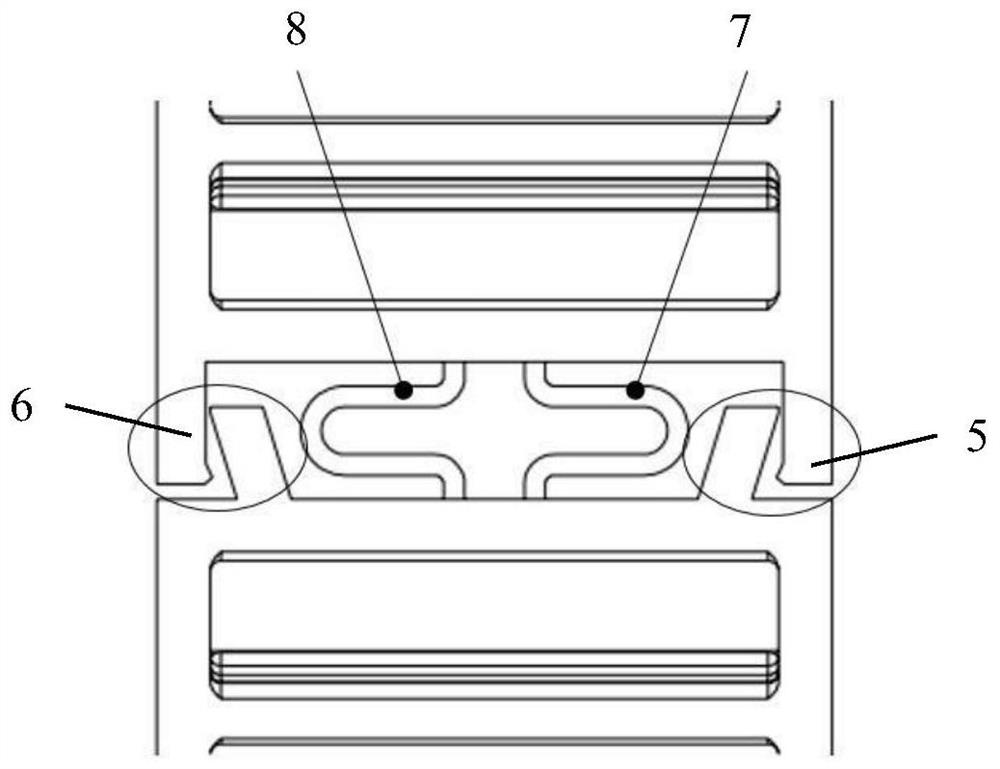

[0027] Such as figure 1 As shown, the cage comprises two cage sections, namely a first cage section 2 and a second cage section 3 . Each cage segment has a row of cage pockets 1 . The two cage sections 2 , 3 extend in the circumferential direction and are here both semi-circular in shape. The two cage sections 2 , 3 are connected to each other by two connections that are elastic in the circumferential direction to form an annular cage. The two connecting parts respectively include a pair of U-shaped springs 7, 8, and the opening directions of each pair of U-shaped springs 7, 8 face each other, and the symmetrical layout of the U-shaped springs 7, 8 can make the cage bear force on both sides in the axial direction balanced. As a result, the tange...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap