A piezometric extension tube for a large-scale penetration test and method of operation thereof

An extension tube and pressure measurement technology, applied in permeability/surface area analysis, pipes, hoses, etc., can solve problems such as reducing the accuracy of measurement data, improve the test success rate, and solve the contact surface gap and side wall flow around The effect of interference and improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

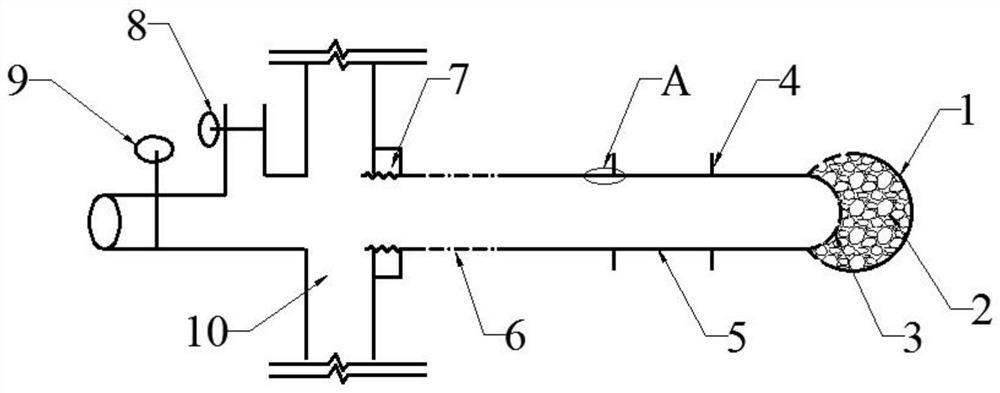

[0024] Such as figure 1 As shown, a pressure measurement extension tube for large-scale penetration tests, including an outer filter 1, a filler material 2, an inner filter 3, a rigid extension tube 5, a flexible extension tube 6, a control valve, a pressure sensor, and a permeameter The inner wall of the box wall 10 is connected with the flexible extension pipe 6, the rigid extension pipe 5 and the inner filter screen 3 successively from left to right, the right end of the rigid extension pipe 5 is connected with the outer filter screen 1 and the outer filter screen 1 is positioned at the right outer side of the inner filter screen 3, The filling material 2 is filled between the inner filter 3 and the outer filter 1, the control valve is respectively connected to the flexible extension pipe 6 and the pressure sensor and the control valve is located on the outer wall of the permeameter box wall 10, and the pressure sensor is connected to the flexible extension pipe 6.

[0025]...

Embodiment 2

[0027] On the basis of Embodiment 1, the shape of the outer filter 1 is spherical, and the shape of the inner filter 3 is hemispherical. The outer filter 1 and the inner filter 3 of this shape reduce the contact area between impurities and the filter (outer filter and inner filter) when filtering the sample, so as to prevent impurities from depositing on the filter, blocking the filter, and affecting the filtration. Effect.

[0028] Further, the outer filter is a spherical structure with a diameter of 2.0-4.0cm, and the inner filter is a hemispherical structure with a diameter of 1.0-2.0cm; preferably the outer filter is a spherical structure with a diameter of 3.0cm, and the inner filter is a diameter of 2.0cm The hemispherical shape of the filter; this size screen filters better than other screen sizes.

[0029] Further, the filler 2 is fine gravel. The fine gravel is conducive to the collection and seepage of water when the seepage sample is passed, reducing the interfere...

Embodiment 3

[0032] On the basis of Example 2, the rigid extension pipe 5 adopts a hollow 304 steel circular pipe. Its tensile strength is better than ordinary stainless steel materials, even reaching the effect of 520MPa. Because of its high strength, when the extension tube is buried in the sample, it can ensure that the extension tube is not deformed and safe when faced with vibration shock in the later stage. High, because its own density is 7.93, so it can adapt to the external environment well when used, and it is not easy to rust.

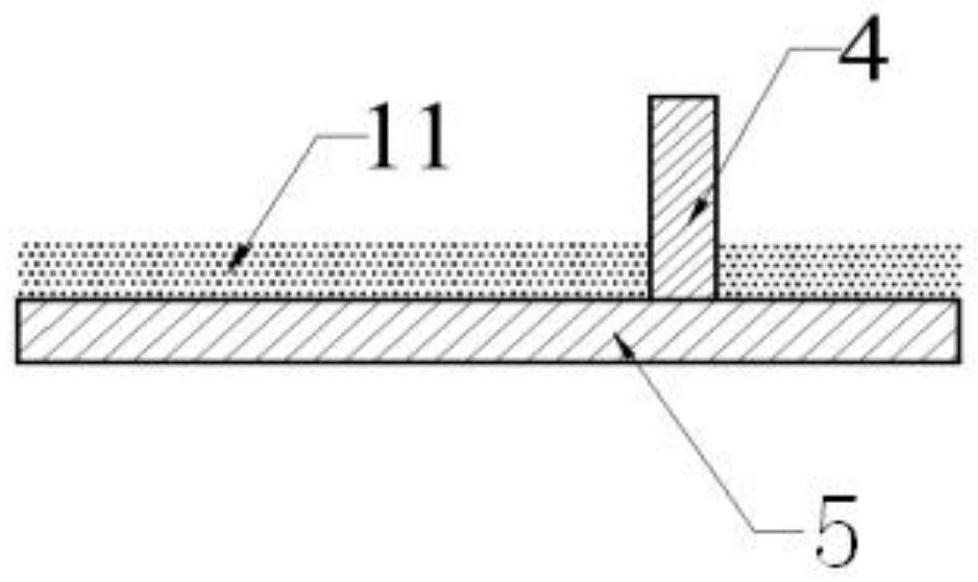

[0033] Such as figure 2 As shown, further, the outer wall of the rigid extension pipe 5 is sleeved with an annular steel sheet 4 . The annular steel sheet 4 can effectively block the pore passage between the outer wall of the rigid extension tube 5 and the sample.

[0034] Further, the rigid extension tube 5 adopts a hollow 304 steel circular tube with a diameter of 2.0 cm and a wall thickness of 0.5 cm; the outer diameter of the annular steel sheet 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com