Particle material feeding device, particle material dispersing device and cooking equipment

A granular material and feeding device technology, which is applied in the field of granular material feeding device and cooking equipment, can solve the problems of poor cooking taste of dishes and inaccurate proportioning of auxiliary materials, so as to achieve accurate output, better cooking taste, feeding and mixing more accurate than

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

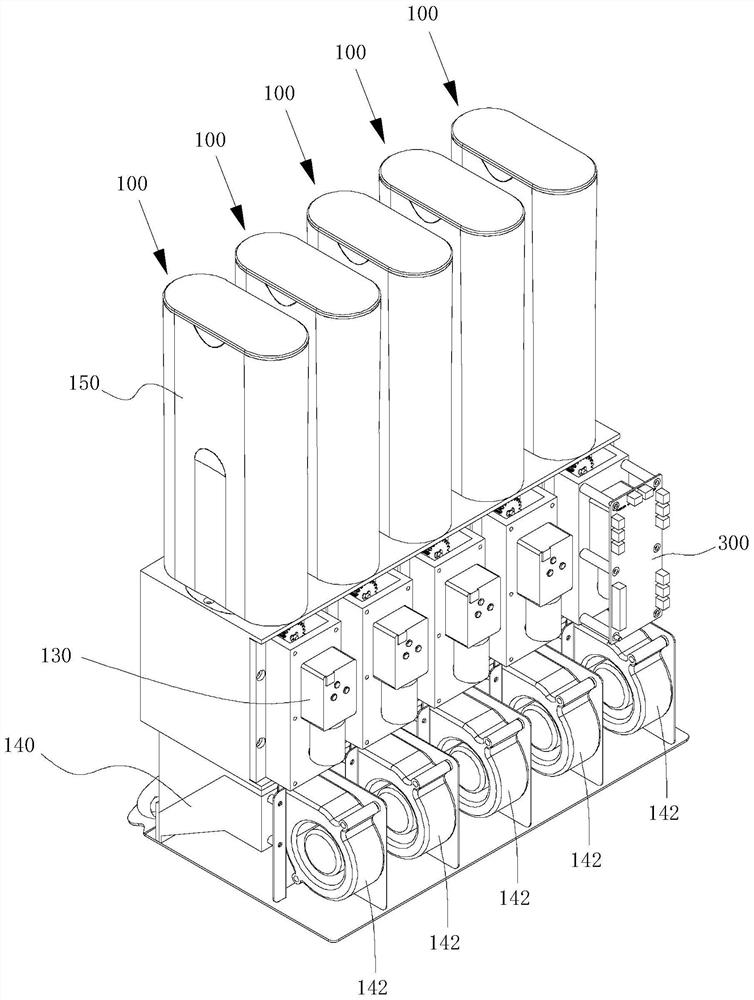

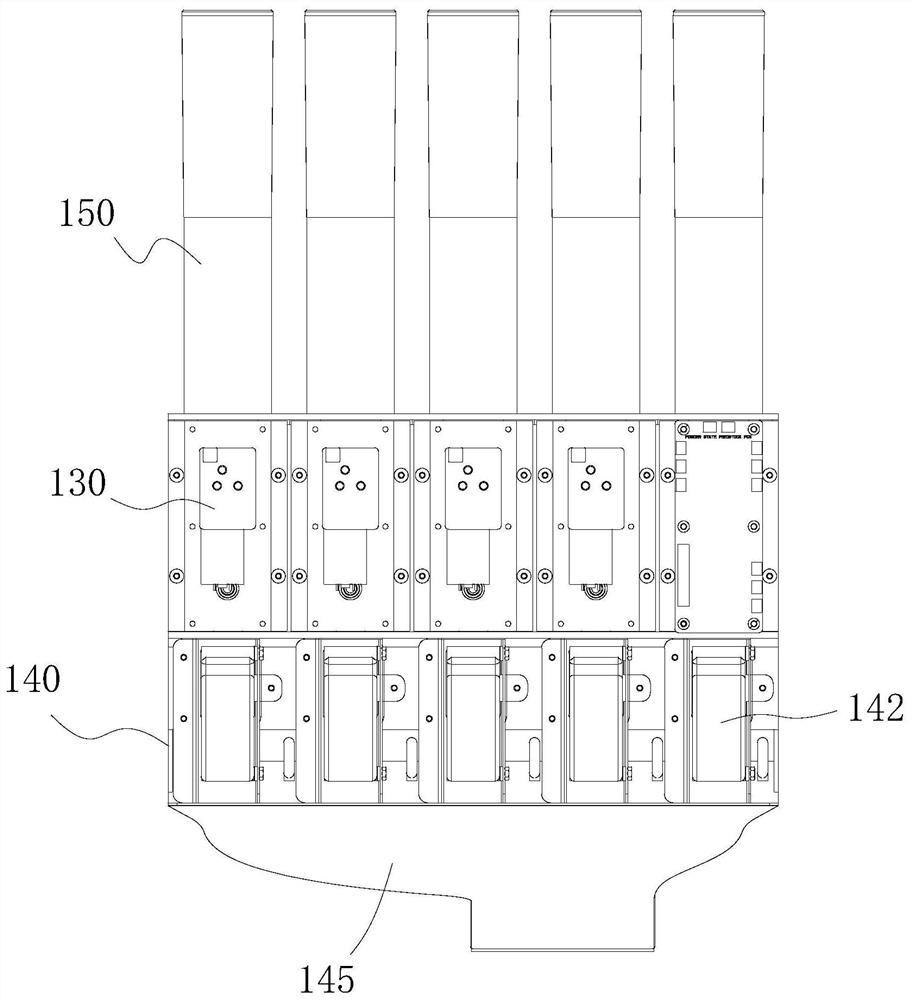

[0031] Such as Figure 1 to 4 As shown, the embodiment of the present invention provides a particulate material feeder 100, in particular, the particulate material feeder includes a first cavity 110, a first loose material 113, and a first shield 114. In the particulate material feeder, the first cavity 110 is provided with a first feed port 111 and a first discharge port 112, wherein the first discharge port 112 is disposed at the bottom position of the first cavity 110; The loofout member 113 can be rotatably provided in the first cavity 110, and the first stopper member 114 can be rotatably disposed at the first discharge port 112, and the outer wall of the first stopper member 114 is provided with a first groove 1141. When the first stopper 114 is rotated, the particulate material in the receiving cavity of the first cavity 110 can be released along the first groove 1141.

[0032] When the feeding is, the particulate material in which the enclosure in the first cavity 110 is co...

Embodiment 2

[0038] Such as Figure 4 , 5 , 7, on the basis of the first example, the particulate material feed apparatus further includes a second cavity 120, a second loose material 121, and a second sheas 122. Among them, the second cavity 120 is disposed in the first cavity 110 and located above the first loose material 113, the second cavity 120 is in communication with the first feed port 111, and the bottom of the second cavity 120 A second discharge opening (not shown) in communication with the receiving cavity of the first cavity 110 is provided, and the second loose material 121 can be rotatably disposed within the second cavity 120, and the second sheas 122 can be Turn it at the second discharge opening, and the second stopper 122 can turn off the second discharge port, wherein a second groove 1221 is provided on the outer wall of the second shutter 122, when the second block During the rotation of the material 122, and the receiving chamber of the second cavity 120 is in communicati...

Embodiment 3

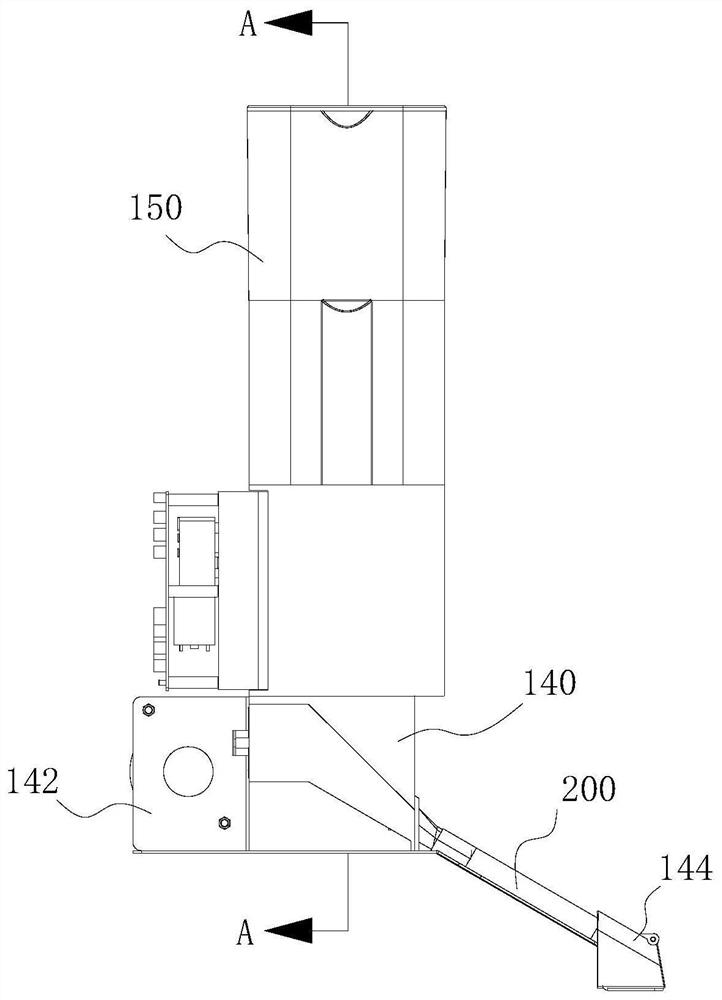

[0043] See image 3 , 8 , 9, on the basis of the first embodiment or the second embodiment, the particulate material feeder also includes a feed assembly 140 and a nozzle 144, wherein the feed assembly 140 includes a third cavity 141 and a blower device 142, in this In the present invention, the blower device 142 is fitted with a fan, and the third cavity 141 is in communication with the first discharge port 112, and the blower device 142 is in communication with the receiving cavity of the third cavity 141, and the third cavity 141 is provided with the first The three discharge port 143, the mouth 144 is connected to the third discharge port 143 to input the particulate material into the target object. When the particle material is dropped by the first discharge port 112 and output from the third discharge port 143, the particulate material is blown into the mouthpiece 144 at this time, the particle material is applied by blowing the particulate material. In the present embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com