A dmtd-cofs material and its modification method and application

A modification method and water adsorption technology, which is applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problems of low adsorption capacity of low-concentration heavy metals and long time required for adsorption and diffusion, and achieve Effects of increasing adsorption active sites, solving low adsorption capacity, and solving molecular diffusion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

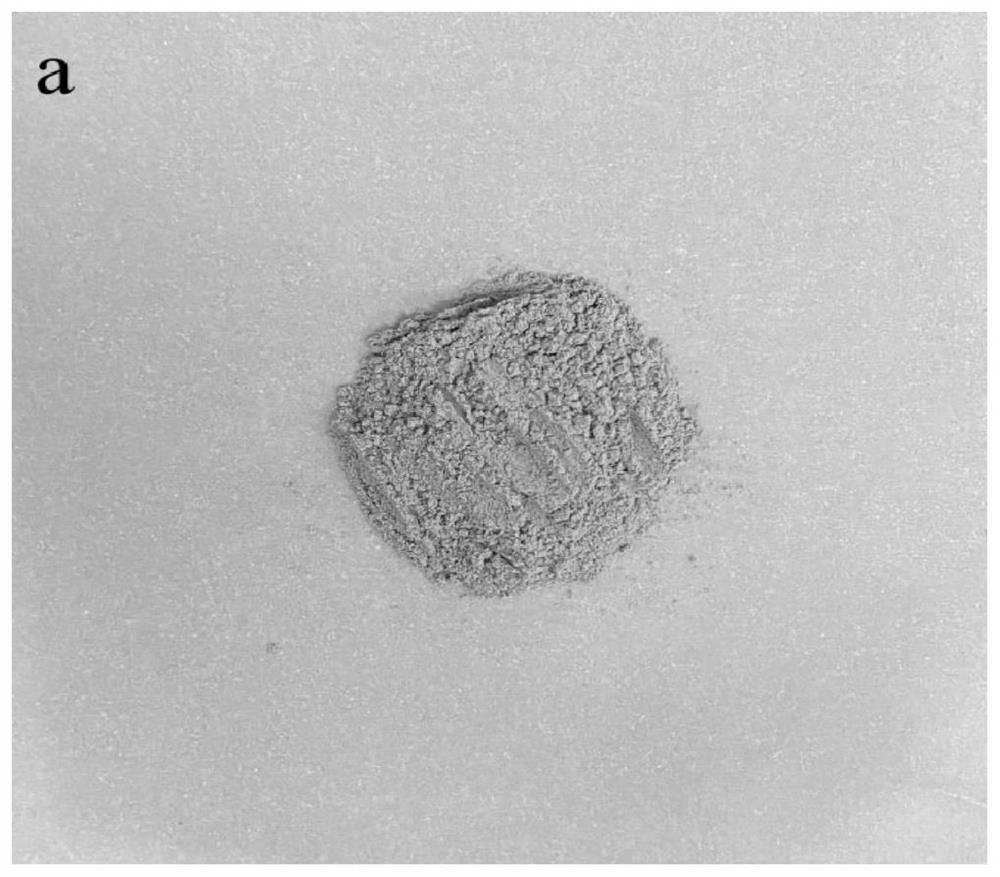

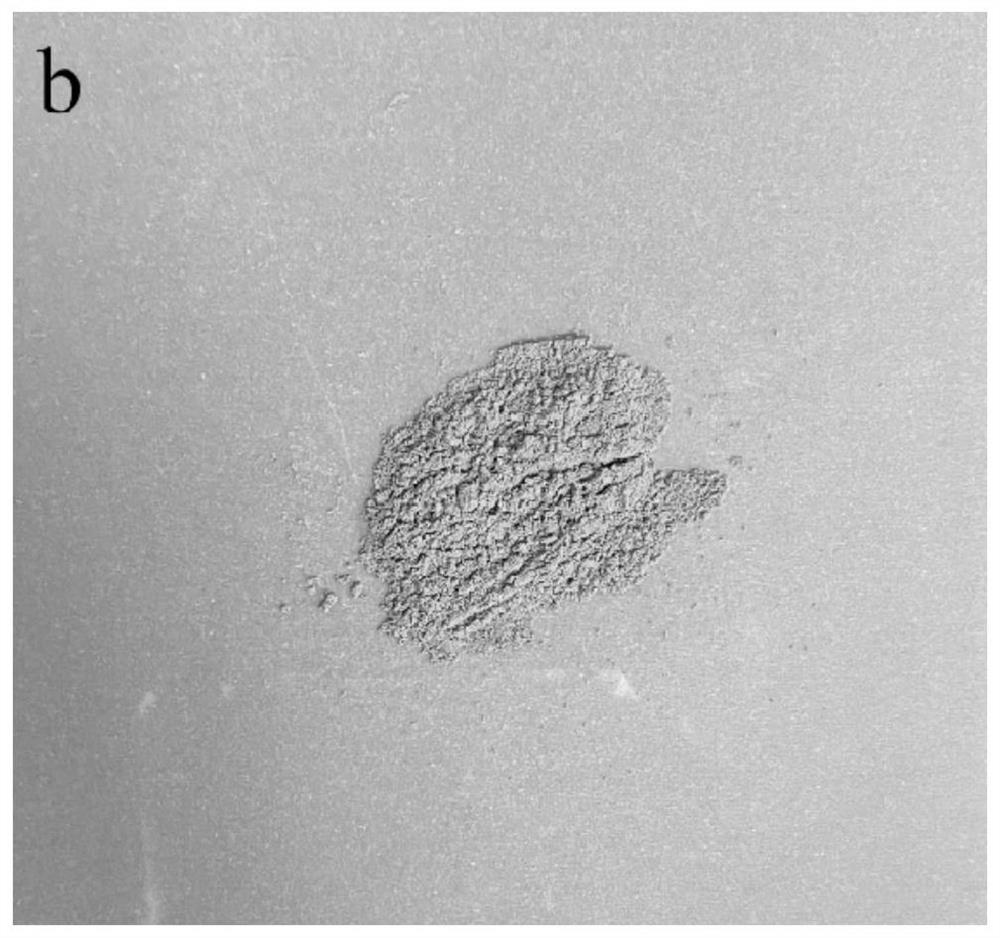

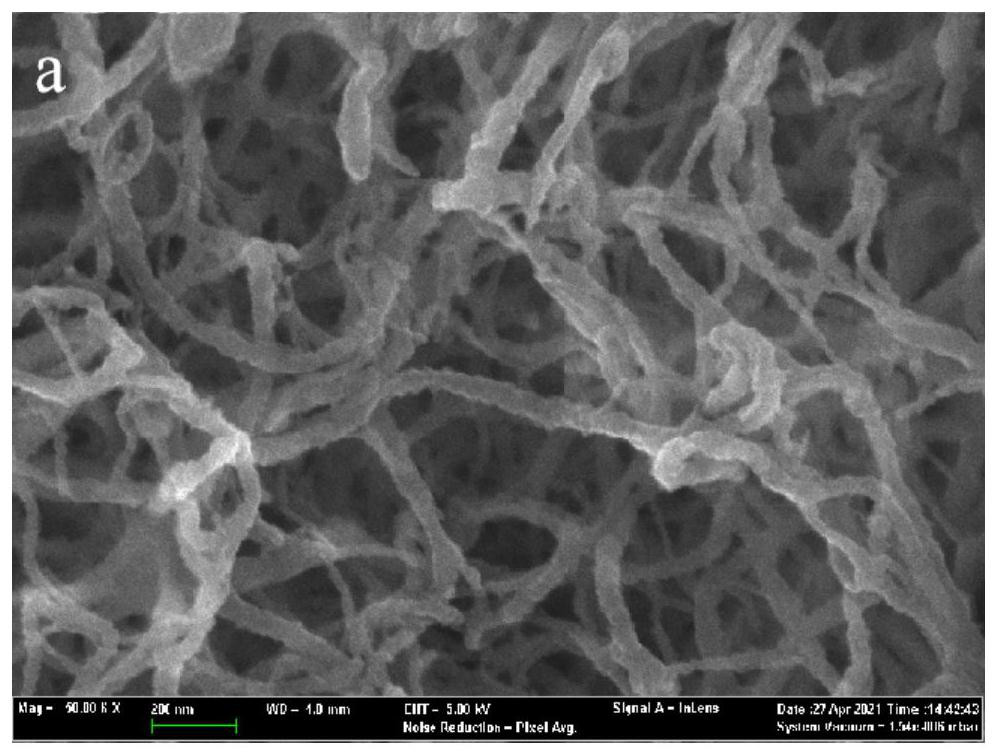

Image

Examples

Embodiment 1

[0051] (1) 2,5-divinylterephthalaldehyde (Dva, 22.3 mg, 0.12 mmol), 1,3,5-tris(4-aminophenyl)benzene (Tab, 28.1 mg, 0.08 mmol), 0.1ml of 6M acetic acid, 0.5ml of n-butanol, 0.5ml of 1,2-dichlorobenzene were added sequentially to a 5ml ampoule. Place ampoules in liquid N 2 Quickly freeze under the bath, vacuumize, freeze-pump-thaw in liquid nitrogen three times, vacuumize the ampoule bottle, and seal the ampoule bottle with a flame spray gun. The ampoule was left to react at 100° C. for 3 days to obtain a yellow-brown precipitate, which was separated by filtration and washed with anhydrous tetrahydrofuran in a Soxhlet extractor for 2 days. The product was dried under vacuum at 50°C to obtain COFs containing C=C double bonds.

[0052] (2) Under the condition of 80 ℃ water bath, in N 2 0.1079 g of DMTD was dissolved in 2 ml of ethanedithiol (the molar ratio of ethanedithiol to DMTD was 34:1) under atmosphere. in N 2 The above solution was added to a 25ml Schreek tube contain...

Embodiment 2

[0070] Carry out the application test to the DMTD-COFs material of the present invention:

[0071] (1) 10 mg of the COFs prepared in Example 1 and the DMTD-COFs sample prepared when the molar ratio of ethanedithiol to DMTD was 34:1 were added to the Pb containing 30 ml 2+ Concentration is 400ppb, Ca hardness is 20ppm, pH=6.5±0.25 solution in Erlenmeyer flask. After constant temperature shaking in a water bath at 20 °C for 5 min, 5.00 ml was taken for centrifugation, the supernatant was passed through a 0.22 μm filter, 1% nitric acid was added to acidify and the volume was adjusted to 10.00 ml, and Pb in the solution was determined by ICP-MS. 2+ Concentration, the measurement result is multiplied by the dilution factor 2 to obtain the actual Pb in the solution 2+ concentration. In this way, the adsorption performance of DMTD-COFs was evaluated and compared with that of unmodified COFs.

[0072] Figure 8 The adsorption performance of the DMTD-COFs samples prepared when the ...

Embodiment 3

[0083] (1) 2,5-divinylterephthalaldehyde (Dva, 22.3 mg, 0.12 mmol), 1,3,5-tris(4-aminophenyl)benzene (Tab, 28.1 mg, 0.08 mmol), 0.1ml of 6M acetic acid, 0.5ml of n-butanol, 0.5ml of 1,2-dichlorobenzene were added sequentially to a 5ml ampoule. Place ampoules in liquid N 2 Quickly freeze under the bath, vacuumize, freeze-pump-thaw with liquid nitrogen three times, vacuumize the ampoule bottle, and seal the ampoule bottle with a flame spray gun. The ampoule was left to react at 100° C. for 3 days to obtain a yellow-brown precipitate, which was separated by filtration and washed with anhydrous tetrahydrofuran in a Soxhlet extractor for 2 days. The product was dried under vacuum at 50°C to obtain COFs containing C=C double bonds.

[0084] (2) Under the condition of 80 ℃ water bath, in N 2 0.0540 g of DMTD was dissolved in 2 ml of ethanedithiol (the molar ratio of ethanedithiol to DMTD was 68:1) under atmosphere. in N 2 The solution was added to a 25 ml Schreek tube containing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap