Asynchronous motor load torque observation method for low-precision encoder occasion

A load torque, asynchronous motor technology, applied in the control of generators, motor generators, electronically commutated motors, etc., can solve problems such as sudden changes, poor speed control performance, etc., to avoid system chattering and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

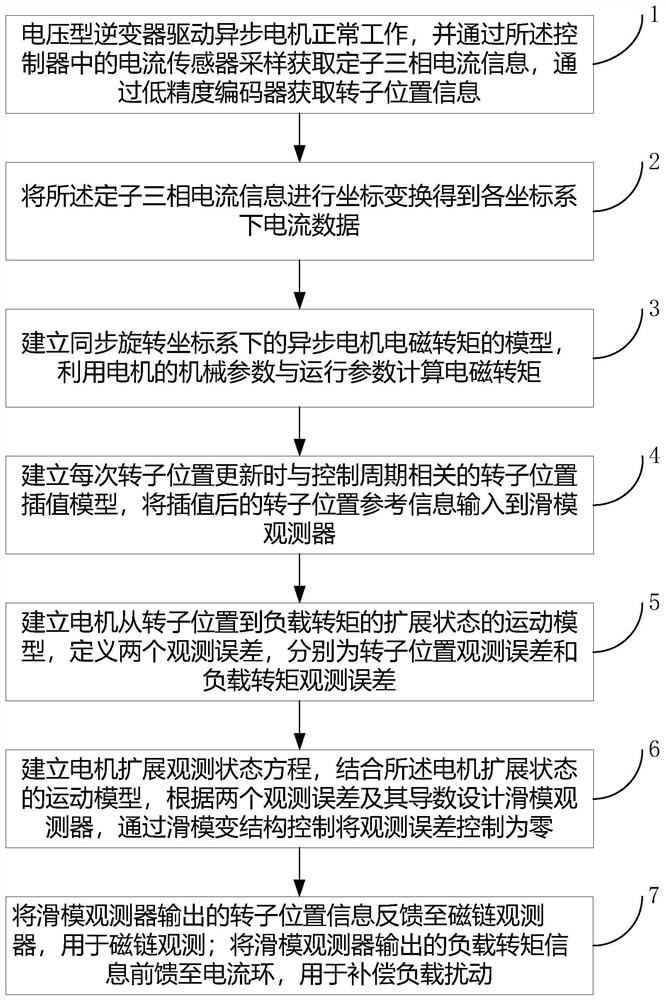

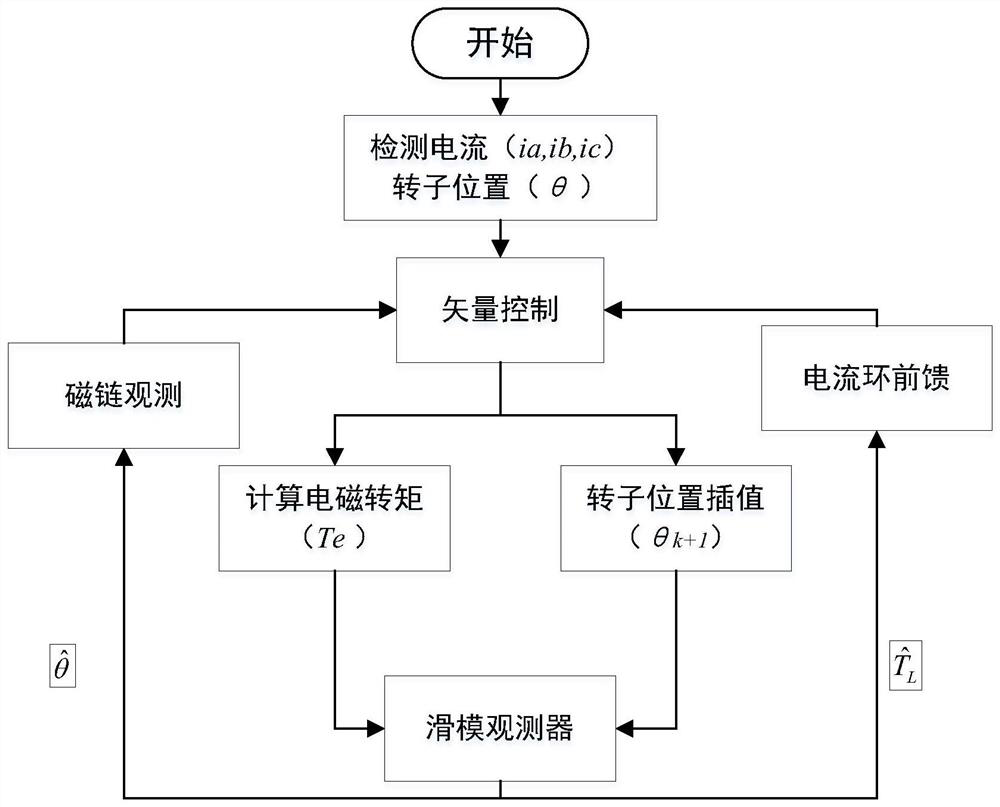

[0022] Such as figure 1 As shown, the embodiment of the present invention provides a method for observing the load torque of an asynchronous motor used in the case of a low-precision encoder, including:

[0023] Step 1, the voltage-type inverter drives the asynchronous motor to work normally, and obtains the three-phase current information of the stator through the current sensor in the controller, and obtains the rotor position information through the low-precision encoder;

[0024] Step 2, performing coordinate transformation on the stator three-phase current information to obtain current data in each coordinate system;

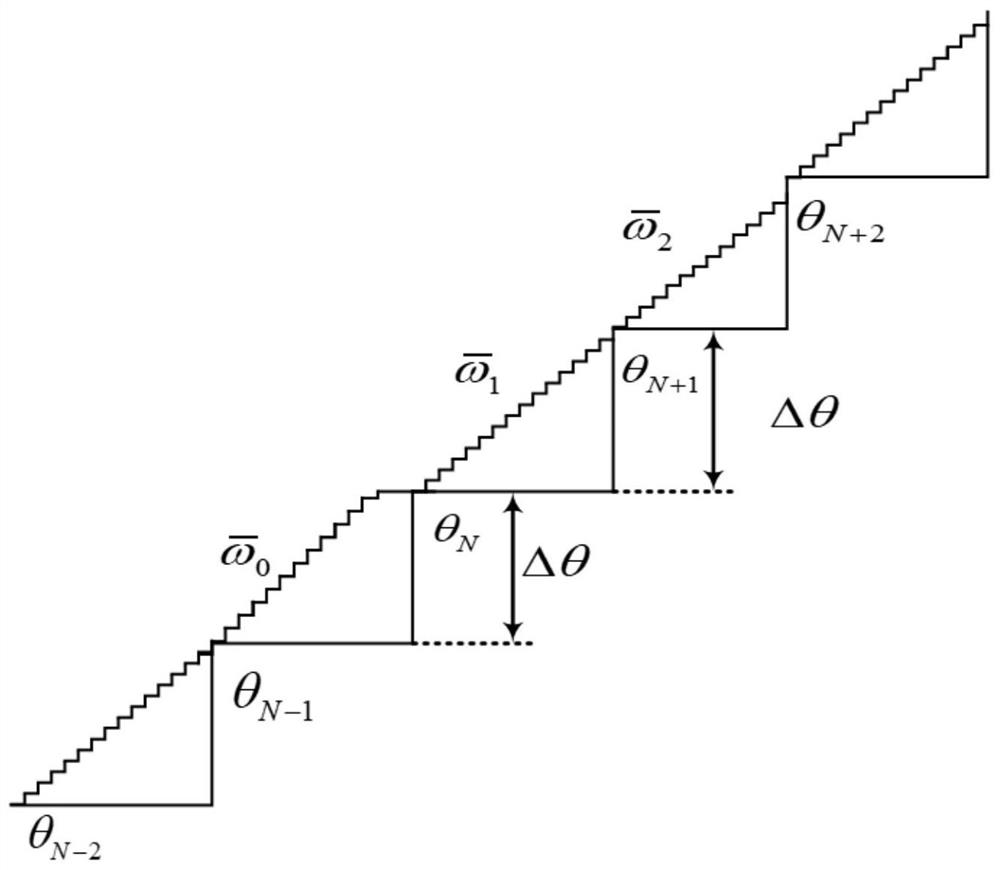

[0025] Step 3, establish a model of the electromagnetic torque of the asynchronous motor under the synchronous rotating coordinate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com