Brick feeding device for converter building rear platform and brick feeding method of brick feeding device

A technology behind the converter and the furnace, which is applied in the field of brick installation on the platform behind the converter furnace, which can solve the problems of threatening the personal safety of the furnace workers, the long path of reversing the furnace lining bricks, and the complicated structure, so as to shorten the path of bricks reversing, The effect of saving manpower and avoiding safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are specific examples of the present invention, further describing the technical solutions of the present invention, but the protection scope of the present invention is not limited to these examples. All changes or equivalent substitutions that do not depart from the concept of the present invention are included in the protection scope of the present invention.

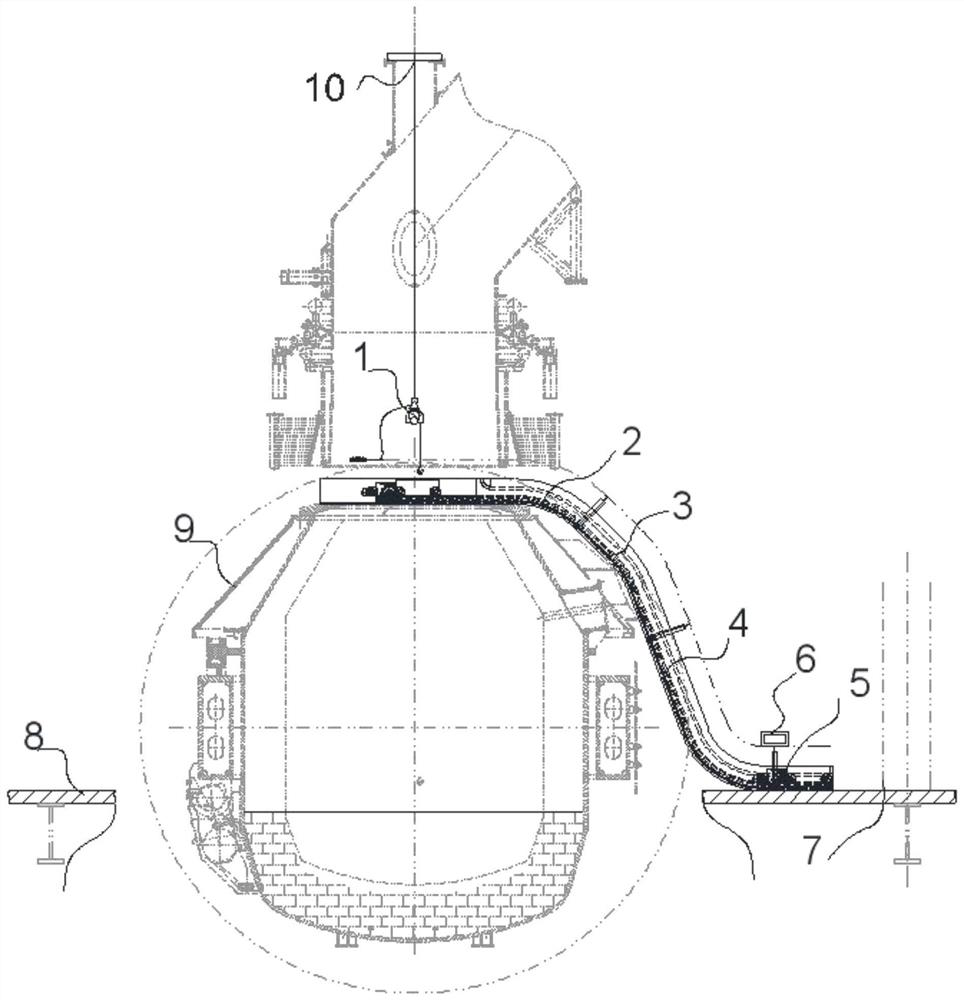

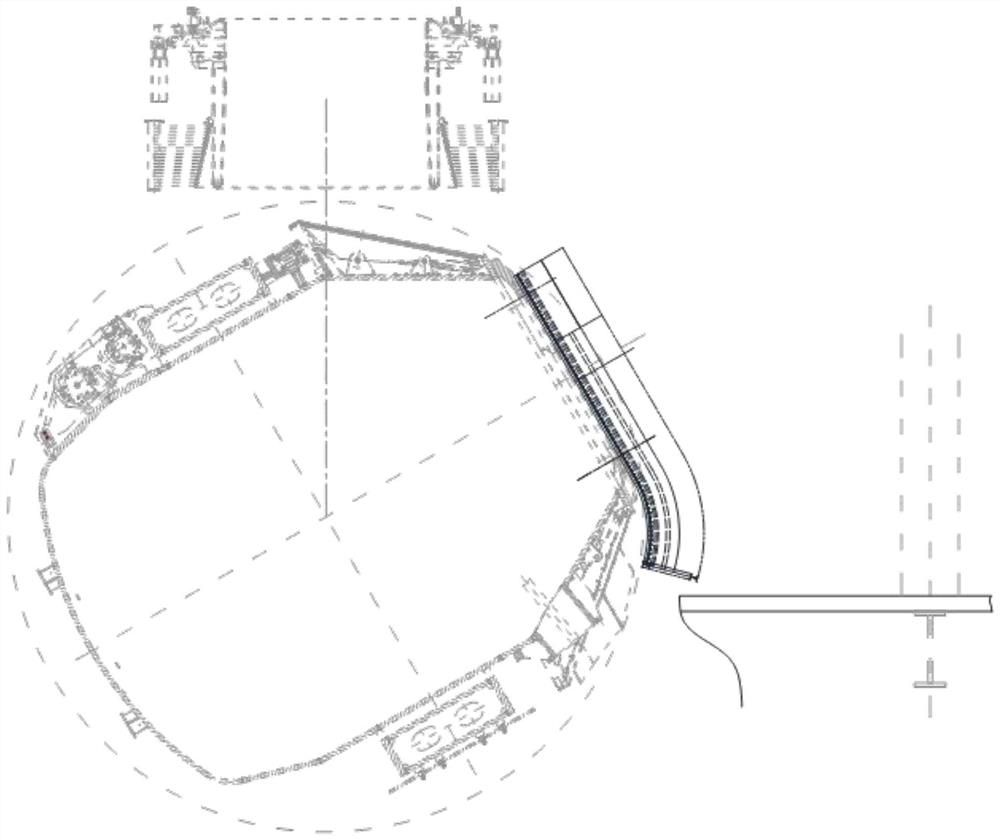

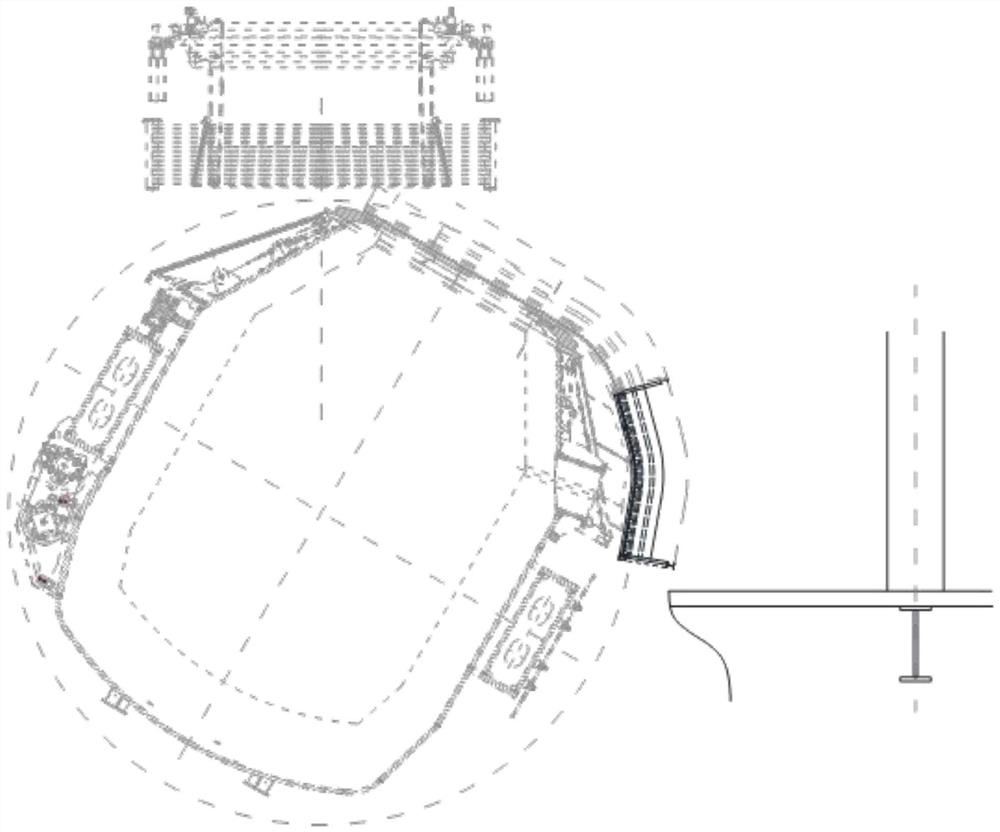

[0023] Such as Figure 1-4 As shown, a device for putting bricks on the rear platform of a converter body, including a converter body 9 and guide rails, the front side of the converter body 9 is the front platform 8, the rear side of the converter body 9 is the rear platform 7, and the rear platform 7 There is a control device 6 on it, and the rear platform 7 of the furnace is connected to the furnace mouth of the converter body 9 through guide rails. The upper brick trolley 5 is arranged on the guide rails. The guide rails include the furnace mouth section guide rail 2, the transition section gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com