Prefabricated cylinder retaining wall for manual hole digging pile and construction method

A technology of manually digging piles and cylinders, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of delay in construction period, slow formation of concrete retaining wall, slow formation of reinforced concrete structure, etc., and achieve the effect of speeding up the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following is attached Figure 1-4 The application is described in further detail.

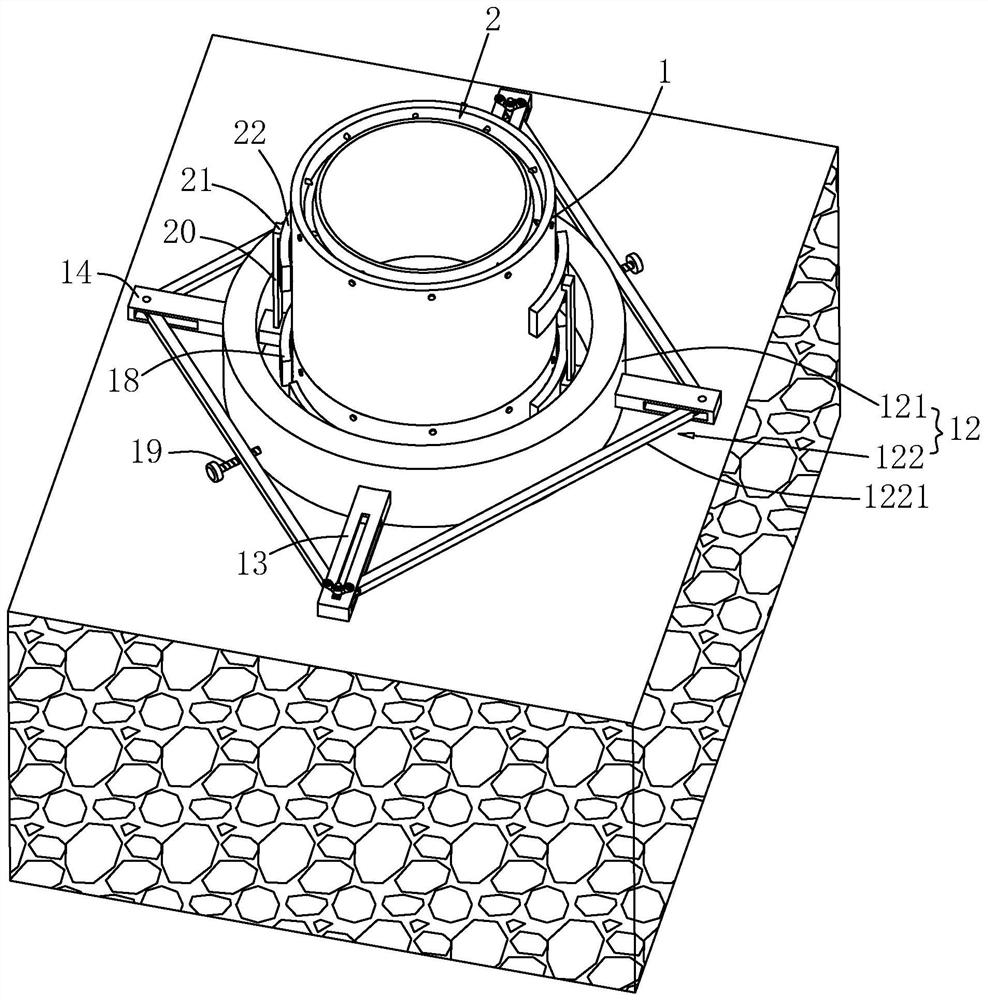

[0036] The embodiment of the present application discloses a prefabricated cylinder retaining wall of manual digging piles. refer to figure 1 , the manual digging pile prefabricated cylinder wall includes a prefabricated cylinder 1 and a positioning assembly 12 for positioning the prefabricated cylinder 1. In this embodiment, the length of the prefabricated cylinder 1 along its axis is 2m.

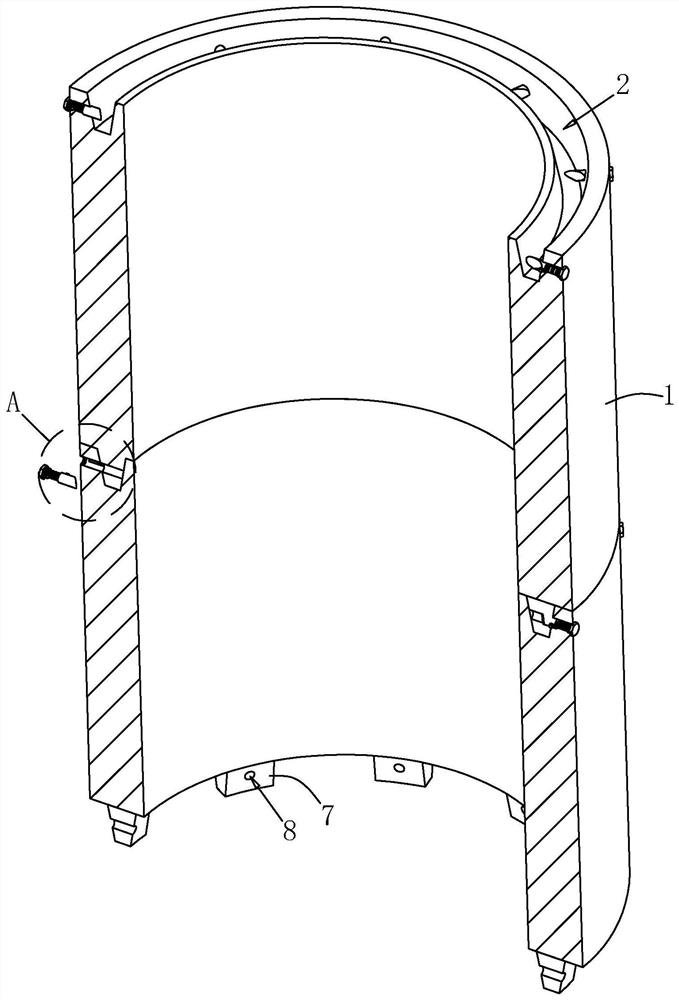

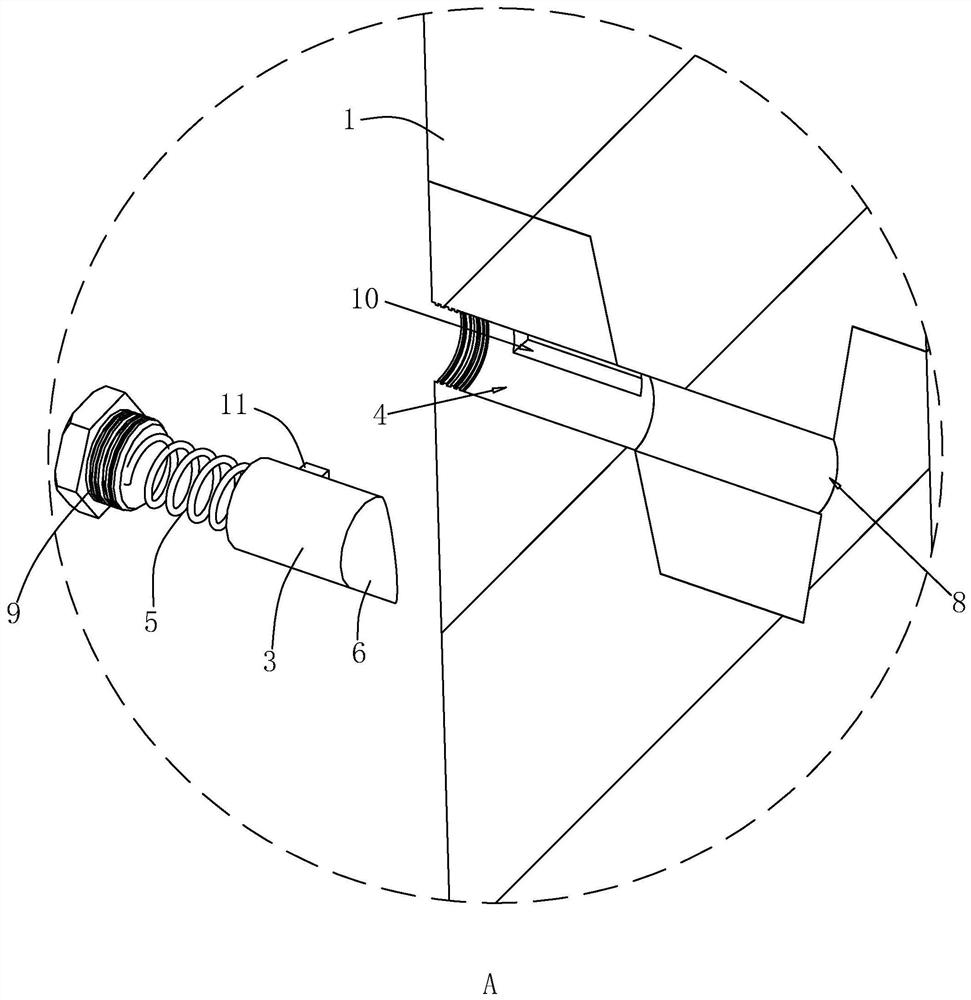

[0037] combine figure 2 with image 3 The prefabricated cylinder 1 is coaxially provided with an annular slot 2 on the outer edge of one end surface thereof, and the cross section of the annular slot 2 along the axis of the prefabricated cylinder 1 is an inverted isosceles trapezoid. The inner wall of the annular slot 2 is provided with a plurality of receiving grooves 4 equidistantly spaced along the axial direction of the prefabricated cylinder 1 , and an insertion rod 3 is movably pierced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com