Fast assembly type building wallboard

A prefabricated and assembled board technology, which is applied in the direction of construction, building components, and building structures, can solve the problems of labor-intensive, low-efficiency, and time-consuming for workers, so as to enhance the safety of use and service life, and improve Applicability, effect of improving connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following is attached Figure 1-7 The application is described in further detail.

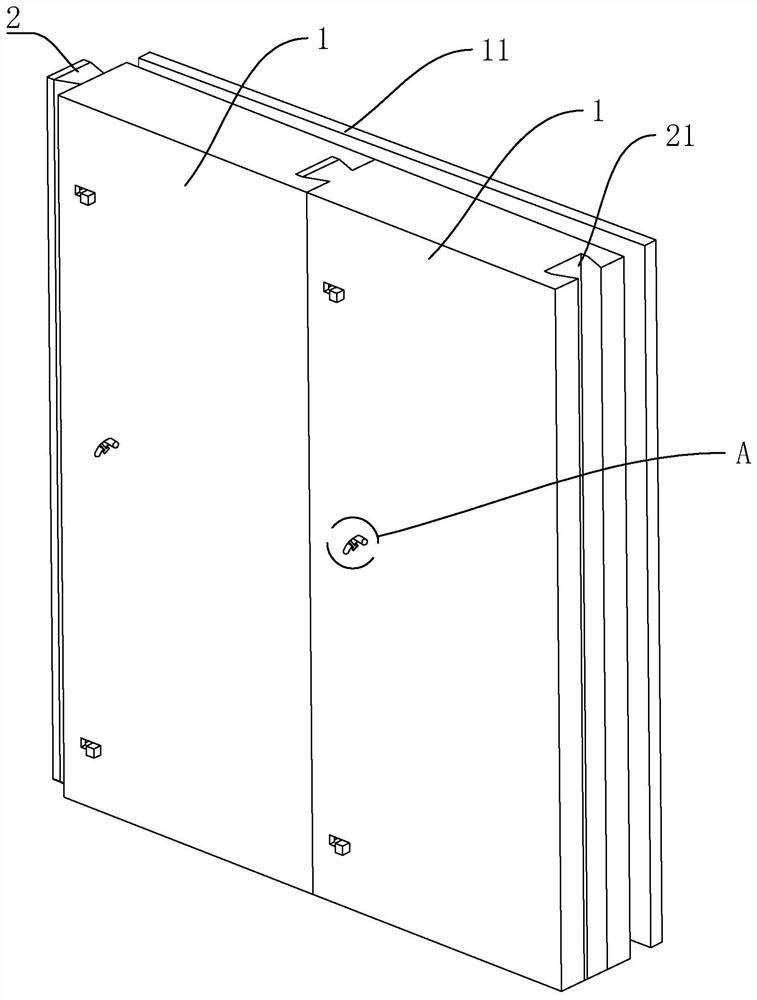

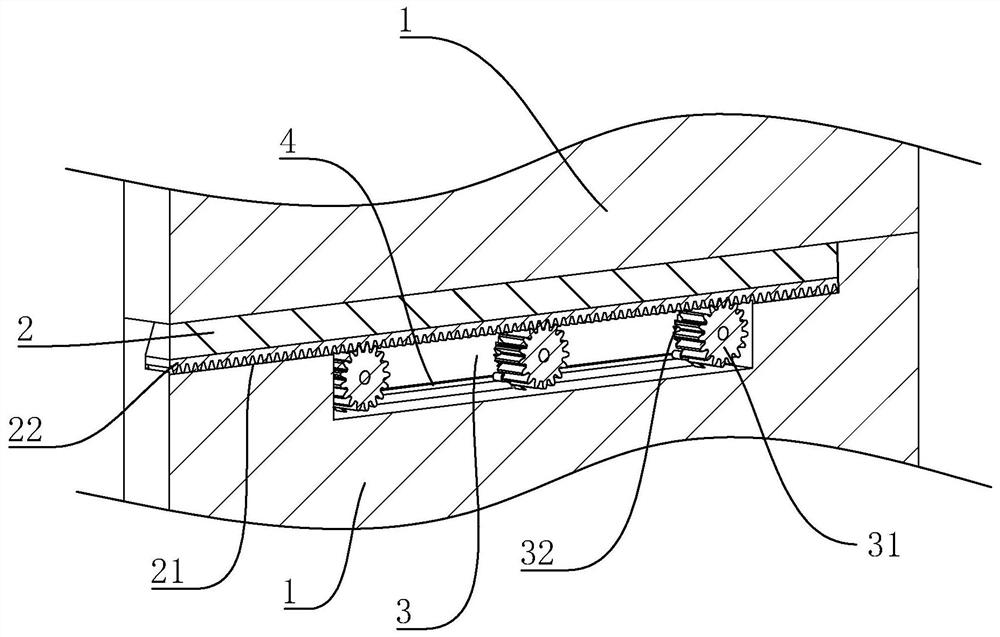

[0035] The embodiment of the present application discloses a quick-assembled building wall panel. refer to figure 1 and figure 2 , including an assembly plate 1, a dovetail block 2 is fixed on the end wall of the assembly plate 1 by bolts, and the length direction of the dovetail block 2 is arranged along the length direction of the assembly plate 1. The end of the assembly plate 1 away from the dovetail block 2 is provided with a dovetail groove 21, the dovetail block 2 on the assembly plate 1 can be inserted into the dovetail groove 21 on another assembly plate 1, the outer wall of the dovetail block 2 and the inner side of the dovetail groove 21 The walls fit together.

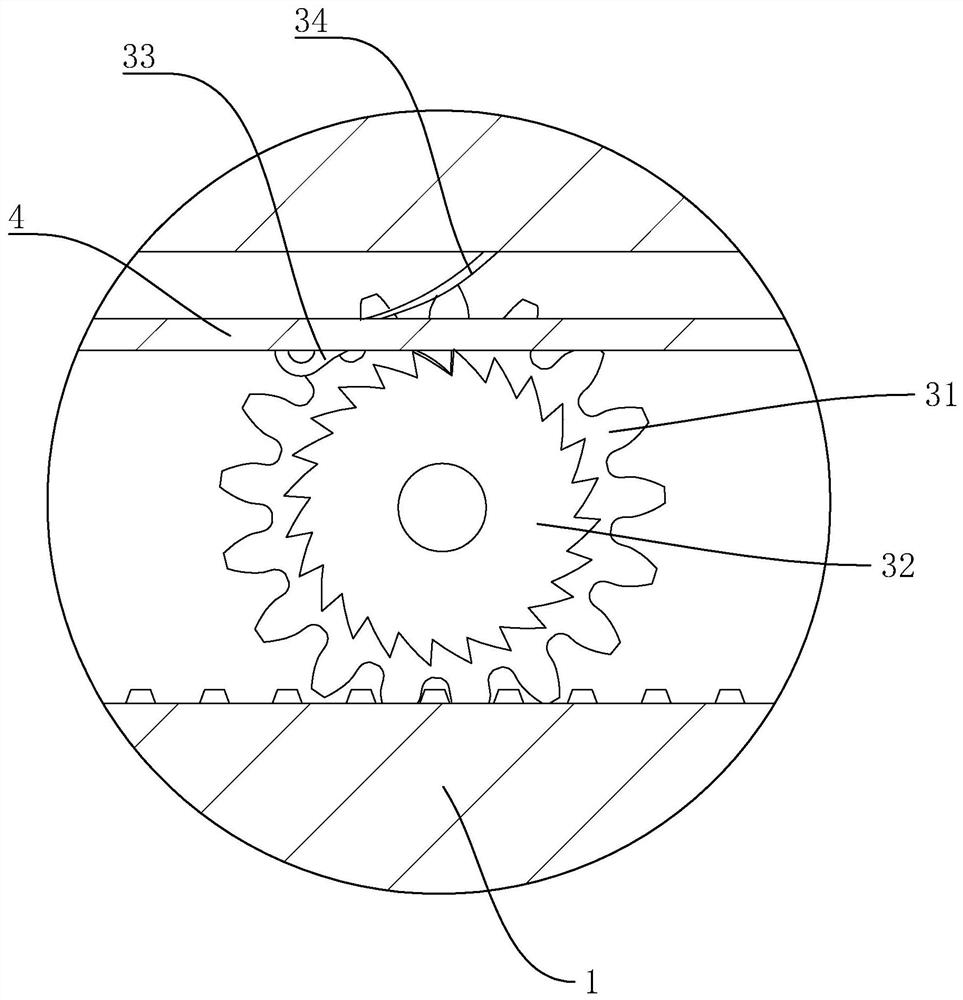

[0036] refer to figure 1 and figure 2 The side of the dovetail block 2 far away from the assembly plate 1 is fixed with a rack 22 by welding, the length direction of the rack 22 is set along the length dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com