Corrosion-resistant invisible hinge for aluminum alloy doors and windows

A technology of aluminum alloy doors and windows and invisible hinges, applied in door/window accessories, hinges with pins, construction, etc., can solve the problems of reducing window stability and reducing window sealing, so as to achieve buffer service life, increase service life, The effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

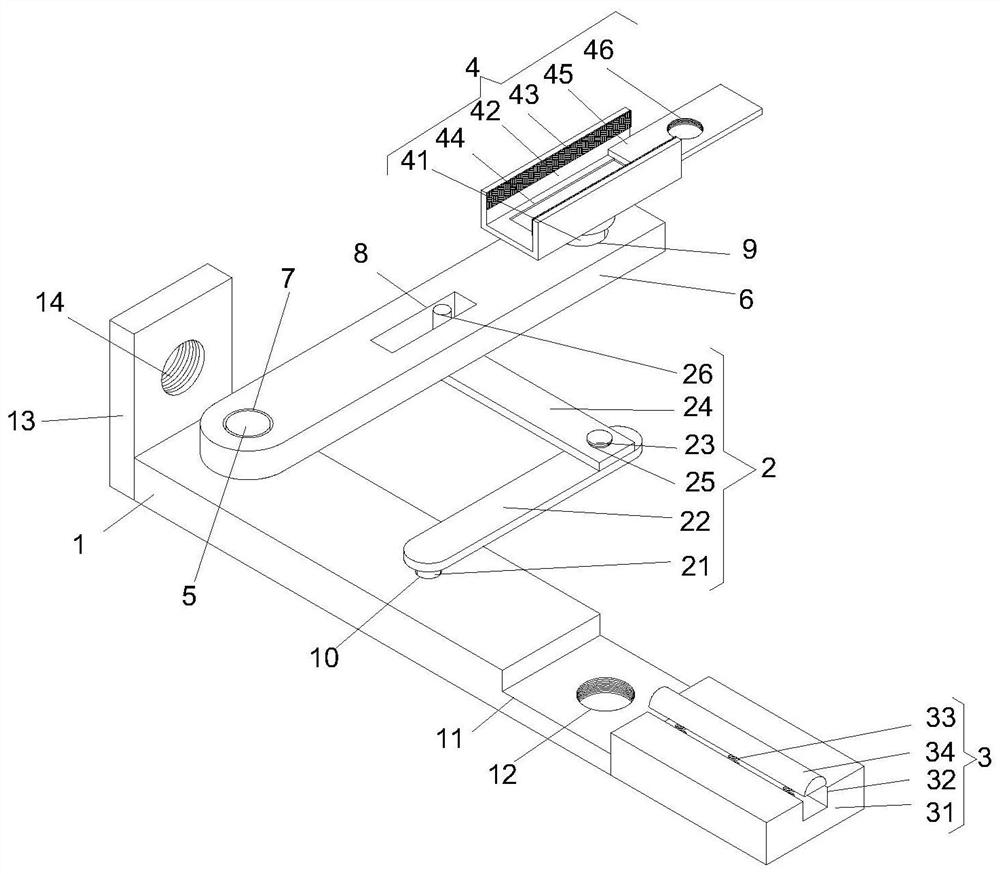

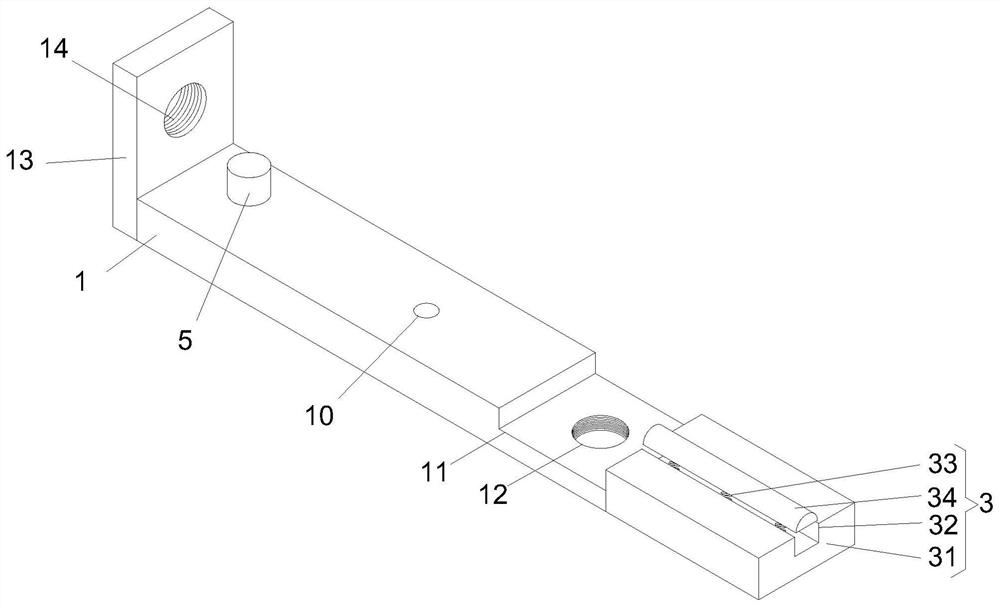

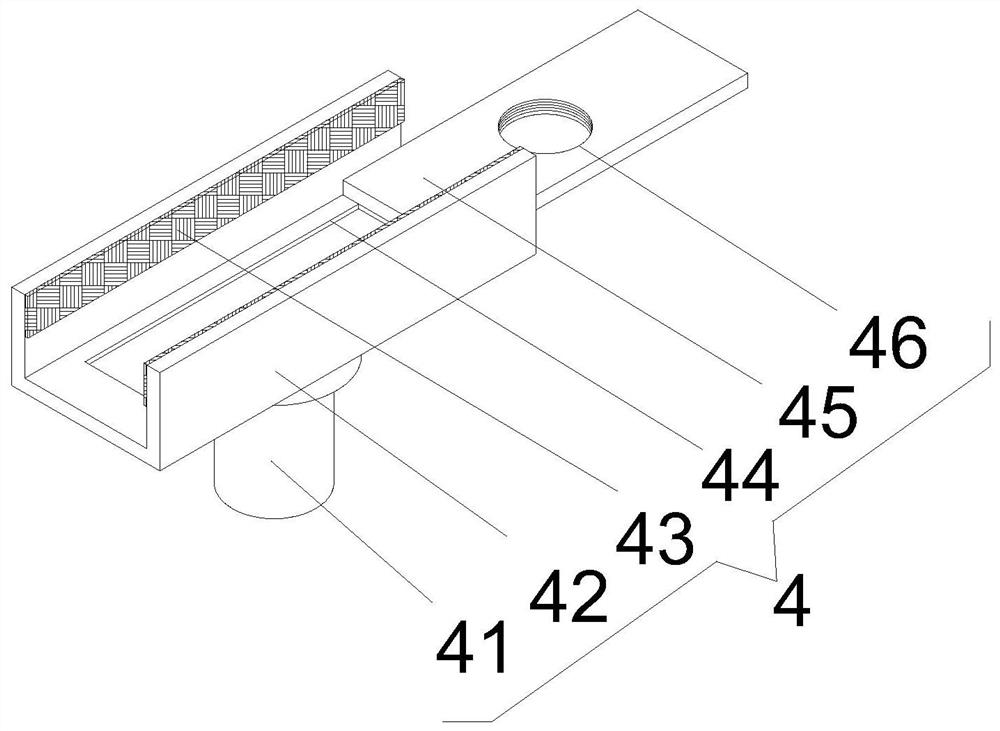

[0029] Embodiment 1: A corrosion-resistant invisible hinge for aluminum alloy doors and windows, such as Figure 1-Figure 4As shown, the installation base 1 is included, the installation base 1 is a rectangular block, the top of the installation base 1 is fixedly installed with a limit post 5, the limit post 5 is a cylindrical rod, and the top of the installation base 1 is vertically provided with a rotating Slot 10, the rotary slot 10 is a circular slot, the rotary slot 10 and the limit column 5 are on the same plane, and the top of the mounting base 1 is vertically provided with a groove 11, and the groove 11 is an L-shaped groove, and the concave The top of the groove 11 is vertically provided with a first threaded groove 12, and the first threaded groove 12 is a circular through hole provided with threads inside. The plate 13 is a rectangular plate, and the upper half of the limiting plate 13 is provided with a second threaded groove 14 transversely. The second threaded gr...

Embodiment 2

[0034] On the basis of Embodiment 1, as shown in figure limit column 5, movable device 2 can also comprise second rotating column 28, and described second rotating column 28 is a cylindrical rod, and second rotating column 28 is installed vertically and movably. Inside the rotating tank 10, a first movable plate 27 is movably installed on the top of the second rotating column 28, the first movable plate 27 is a rectangular plate, and the first movable plate 27 is away from the side wall surface of the second rotating column 28 The first connecting column 29 is fixedly installed, and the first connecting column 29 is a cylindrical column, and the outer circle of the first connecting column 29 is sleeved with a third connecting plate 210, and the third connecting plate 210 is a circle at both ends. The plate of the hole, the third connecting plate 210 is socketed on the second connecting post 211 on the side of the third connecting plate 210 away from the first connecting post 29...

Embodiment 3

[0037] On the basis of Example 1, as Figure 6 As shown, the buffer device 3 can also include a second buffer base 35, the second buffer base 35 is a rectangular block, and the middle position of the top of the second buffer base 35 is vertically provided with a sinking groove 36, and the sinking groove 36 is rectangular Groove, the inner wall surface that falls into the groove 36 is horizontally fixedly installed with fixed rod 37, and described fixed rod 37 is cylindrical elongated rod, and the outer circle place of fixed rod 37 is movably installed with stopper 38, and described stopper 38 is rectangular block A baffle block 39 is fixedly installed on the top of the block 38, and the baffle block 39 is a triangular block.

[0038] When in use, because the inner wall surface of the sinking groove 36 is laterally fixedly equipped with a fixed rod 37, the outer circle of the fixed rod 37 is movably equipped with a stopper 38, and the stopper 38 moves up and down at the outer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com