Multi-channel circulating oil supply valve

A technology of circulating oil supply and core rotation, applied in multi-port valves, valve details, valve devices, etc., can solve the problems of limited space on site, inability to achieve oil injection point flow, unacceptable to users, etc., and achieve good expansion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

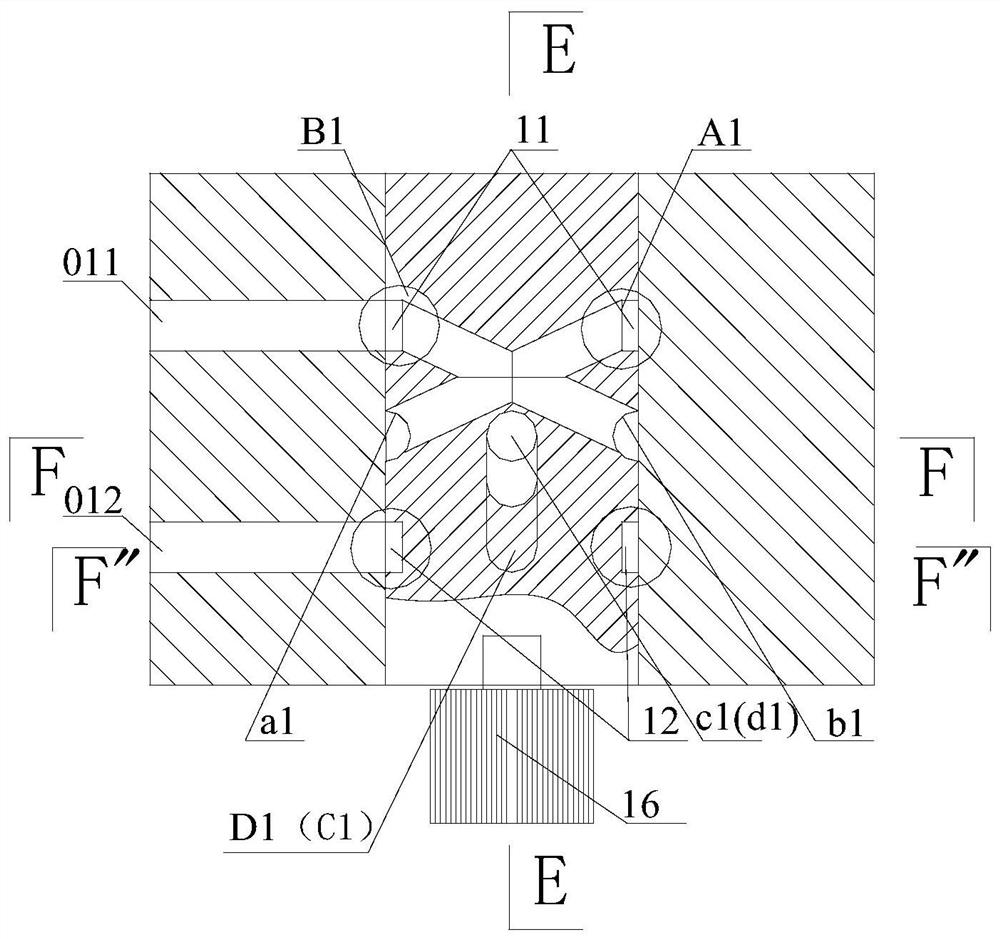

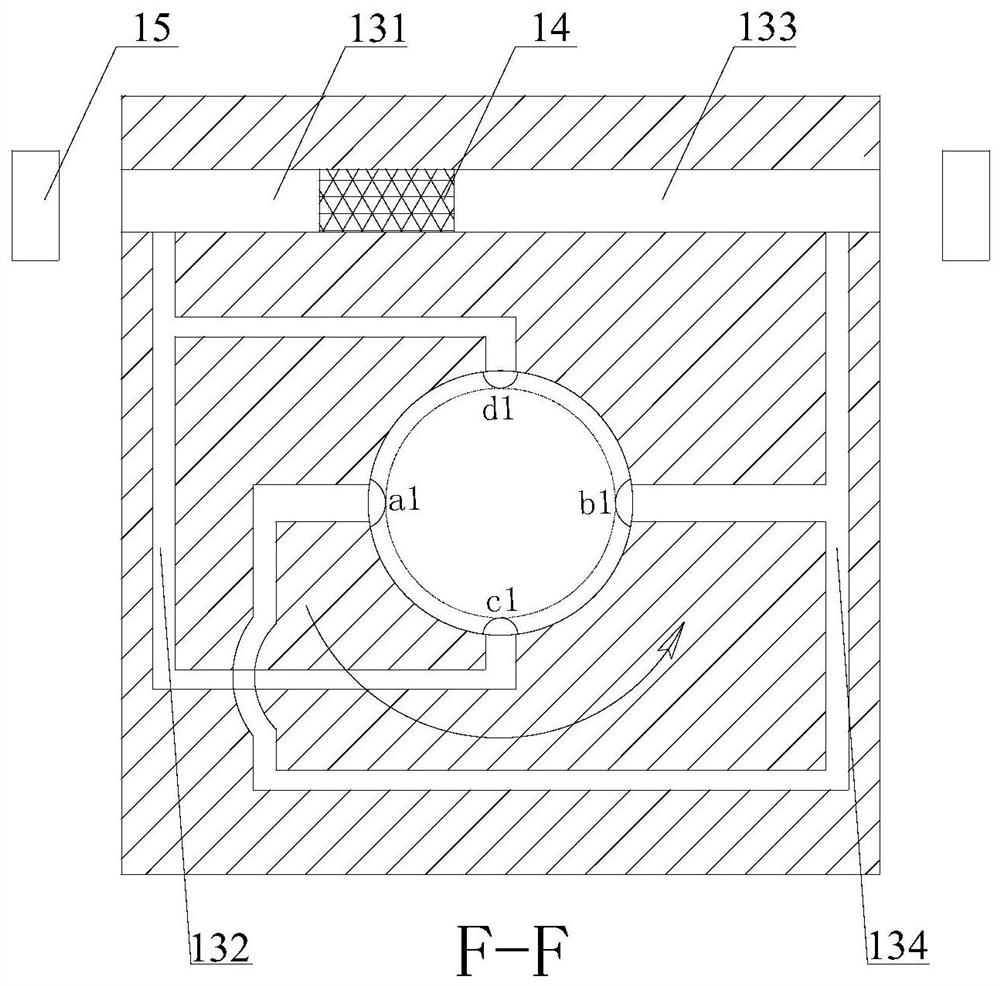

[0036] Such as Figures 5 to 9 As shown, the multi-channel oil supply valve in this embodiment includes a rotor and a stator with a rotor cavity, and the rotor is rotated in the rotor cavity, and the inner wall of the rotor cavity and the outer wall of the rotor are liquid Seal fit.

[0037] The rotating core includes a liquid circuit mechanism, and the liquid circuit mechanism includes a liquid inlet unit and a liquid outlet unit.

[0038] The liquid inlet unit includes a liquid inlet structure, and the liquid inlet structure includes a group of liquid inlet channels and a liquid inlet annular groove 11 arranged on the rotating core, and the liquid inlet annular groove is arranged at the On the same cross-section of the outer wall at one end of the core, the liquid inlet channel is composed of two cross-connected liquid inlet pipes on the rotor core, wherein the liquid inlets B1 and A1 of the two liquid inlet pipes are opposite to each other. It is arranged in the liquid in...

Embodiment 2

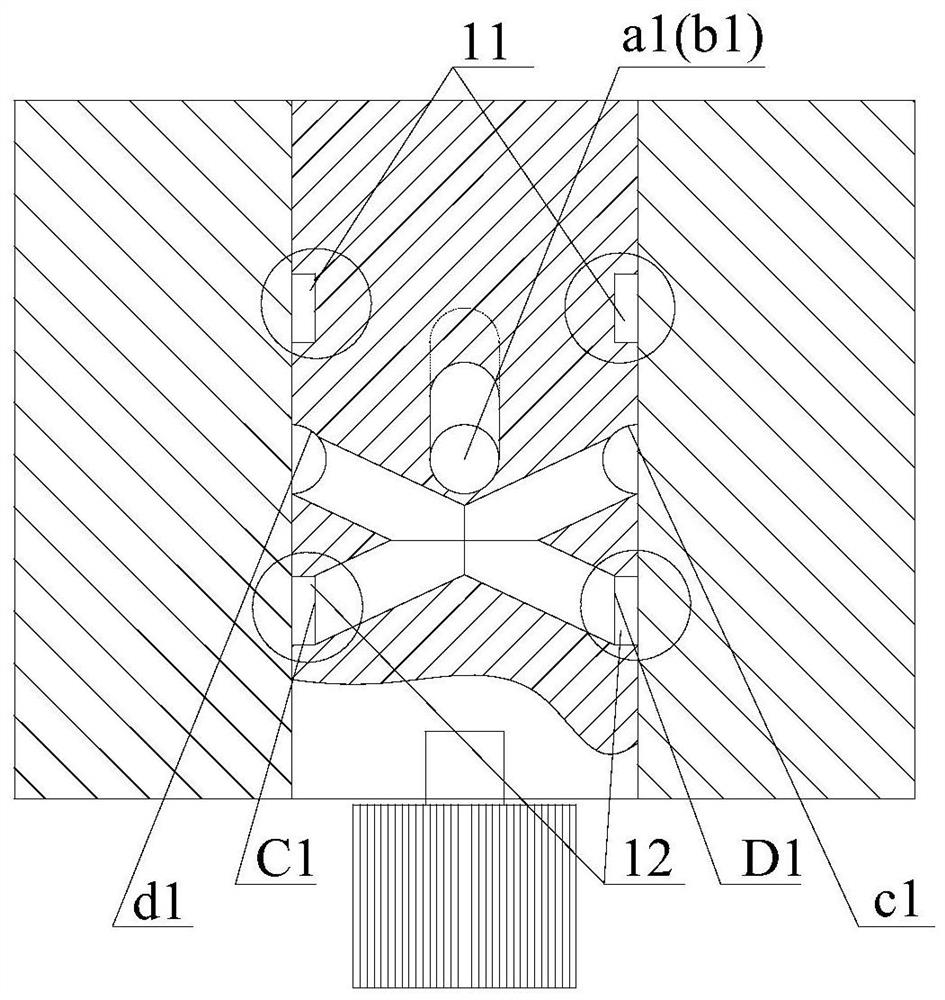

[0054] As a modification of Embodiment 1, the length of the rotor core and the stator is doubled, and the liquid inlet unit and a liquid outlet unit are mirrored on the other side of the rotor core; as Figure 10 and Figure 11 As shown, a form of one-input and four-outlets can be formed in which liquid enters the middle and outputs at both ends.

Embodiment 3

[0056] Such as Figure 12 and Figure 13 As shown, in this embodiment, the angle formed between the line between the liquid inlets of the two liquid outlet pipes and the line between the liquid outlets of the two liquid inlet pipes is 45 degrees. It has 4 outlets correspondingly, which can supply oil to 4 points at the same time. Its specific structure is as follows:

[0057] It includes a rotating core and a stator with a rotating core cavity, the rotating core is rotatably arranged in the rotating core cavity, and the inner wall of the rotating core cavity and the outer wall of the rotating core are liquid-tightly matched.

[0058] The rotating core includes a liquid circuit mechanism, and the liquid circuit mechanism includes a liquid inlet unit and a liquid outlet unit.

[0059] The liquid inlet unit includes a liquid inlet structure, and the liquid inlet structure includes a group of liquid inlet channels and a liquid inlet annular groove 11 arranged on the rotating co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com